Equipment delivery detection method and device, electronic equipment and storage medium

A factory inspection and factory test technology, which is applied in the direction of error detection/correction, electrical digital data processing, software testing/debugging, etc., can solve the pressure of factory test program development, high time cost, and factory test program development/verification time compression and other problems, to achieve the effect of solving the low efficiency of factory inspection and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

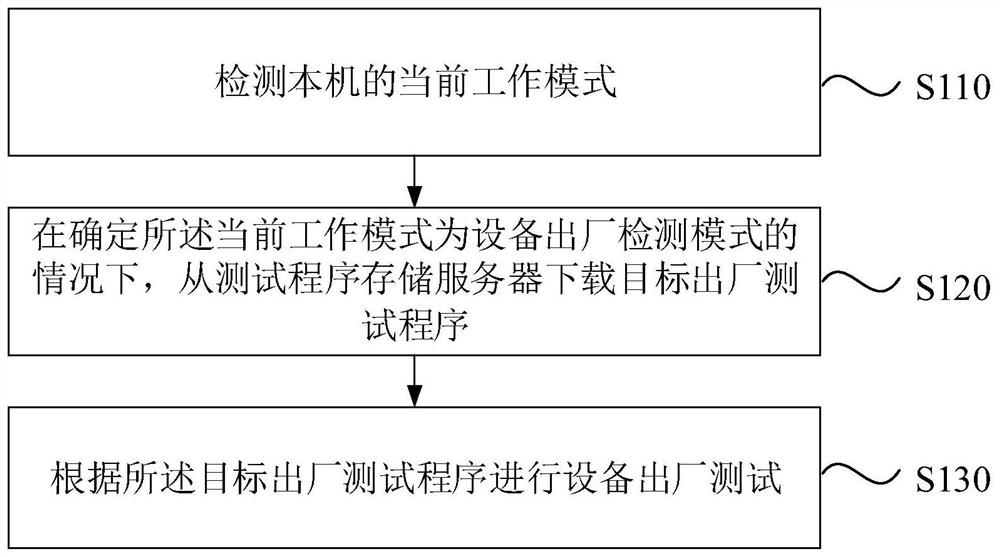

[0029] figure 1 It is a flowchart of a method for ex-factory inspection of equipment provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where the equipment under test downloads the target ex-factory test program from the server for ex-factory inspection. This method can be implemented by the equipment ex-factory inspection device. Execution, the device can be implemented by software and / or hardware, and generally can be integrated in electronic equipment, the electronic equipment can be a device under test, and used in conjunction with a server for storing the target factory test program. Correspondingly, such as figure 1 As shown, the method includes the following operations:

[0030] S110. Detect the current working mode of the machine.

[0031] In the embodiment of the present invention, the device under test may be a device that needs to be tested at the factory, and any device that needs to be tested at the factory can be u...

Embodiment 2

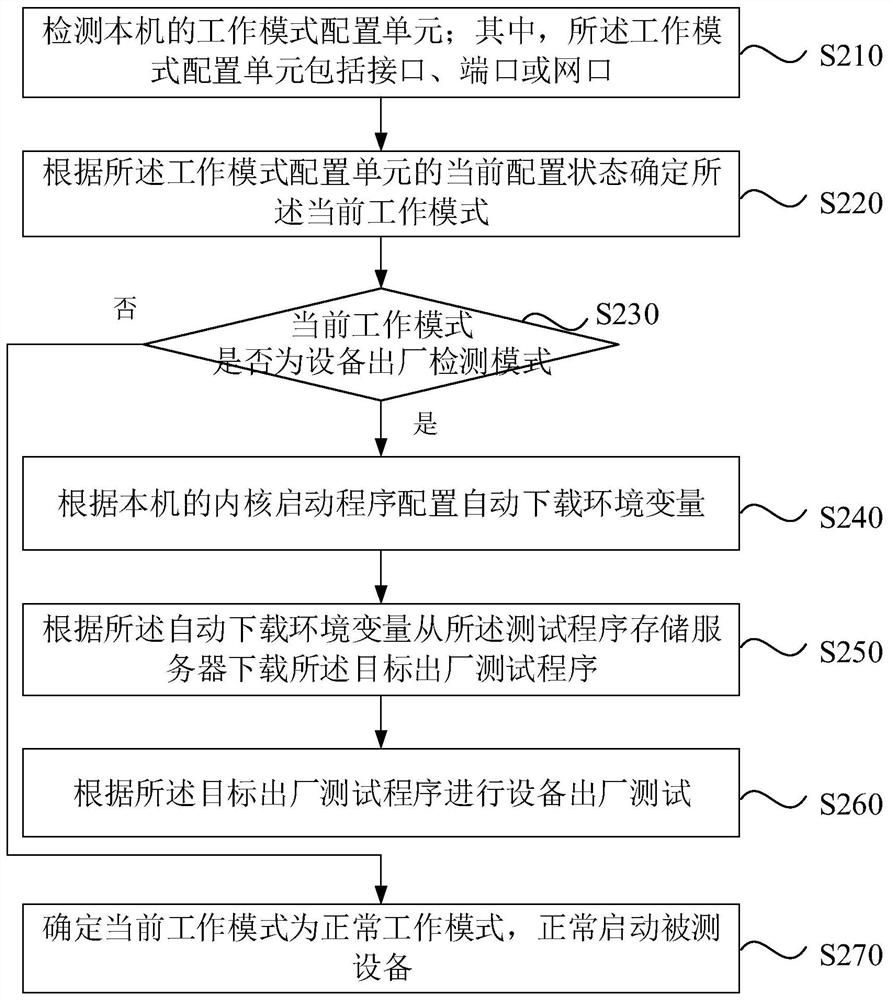

[0045] image 3 It is a flow chart of a method for ex-factory inspection of equipment provided by Embodiment 2 of the present invention. This embodiment is embodied on the basis of the above-mentioned embodiments. The program storage server downloads the target delivery test program and performs multiple specific optional implementations of the device delivery test according to the target delivery test program. Correspondingly, such as image 3 As shown, the method of this embodiment may include:

[0046] S210. Detect the working mode configuration unit of the local machine; wherein, the working mode configuration unit includes an interface, a port or a network port.

[0047] S220. Determine the current working mode according to the current configuration state of the working mode configuration unit.

[0048] Wherein, the working mode configuration unit can be used to configure the working mode of the device under test. Optionally, the operating mode configuration unit can ...

Embodiment 3

[0084] Figure 4 It is a schematic diagram of an equipment delivery inspection device provided in Embodiment 3 of the present invention, as shown in Figure 4 As shown, the device includes: a current working mode detection module 310, a target delivery test program download module 320 and a device delivery test module 330, wherein:

[0085] The current working mode detection module 310 is used to detect the current working mode of the machine;

[0086] The target delivery test program download module 320 is used to download the target delivery test program from the test program storage server under the condition that the current operating mode is determined to be the equipment delivery detection mode;

[0087] The equipment delivery test module 330 is configured to perform the equipment delivery test according to the target delivery test procedure.

[0088] The embodiment of the present invention independently detects the current working mode of the machine through the teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com