Production and maintenance scheduling method and system based on improved grey wolf algorithm

A scheduling method and algorithm technology, applied in computing, artificial life, computing models, etc., can solve problems such as the inability to coordinate production and maintenance scheduling, achieve efficient and accurate collaborative scheduling, reduce enterprise operating costs, and ensure update efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

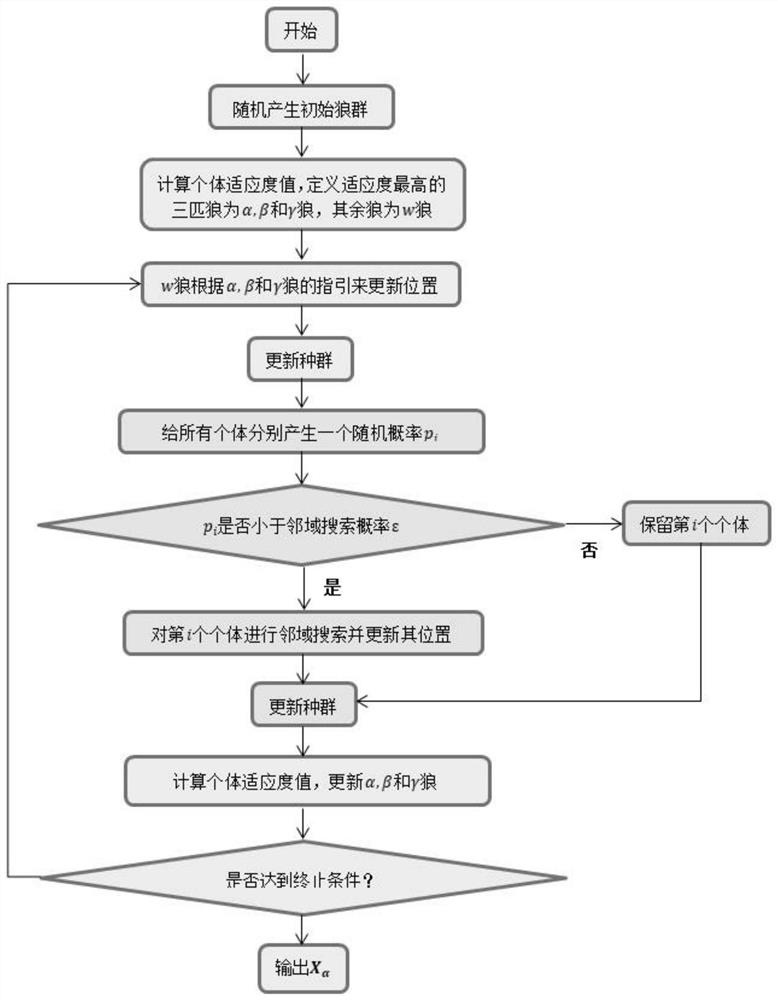

[0116] In the first aspect, the present invention first proposes a production and maintenance scheduling method based on the improved gray wolf algorithm, see figure 1 , the method includes:

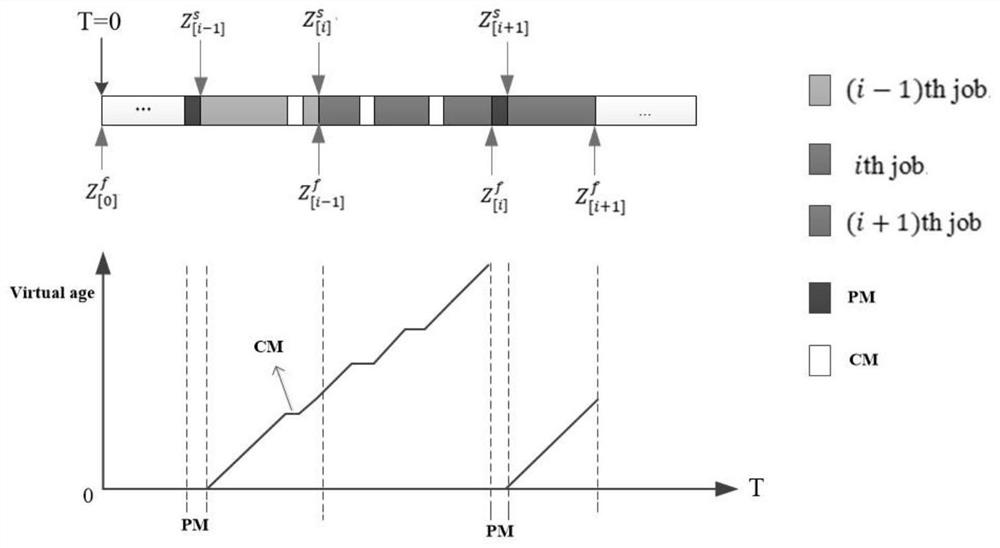

[0117] S1. Input parameters of the initialization algorithm, including the number n of workpieces and the delivery date of workpieces d j , the unit time delay cost w of the workpiece j , unit production cost c l , the time required for a preventive maintenance activity t p and cost c p , the time required for a corrective maintenance activity t r and cost c r , the virtual service age at the initial moment of the machine and the number of preventive maintenance experienced m;

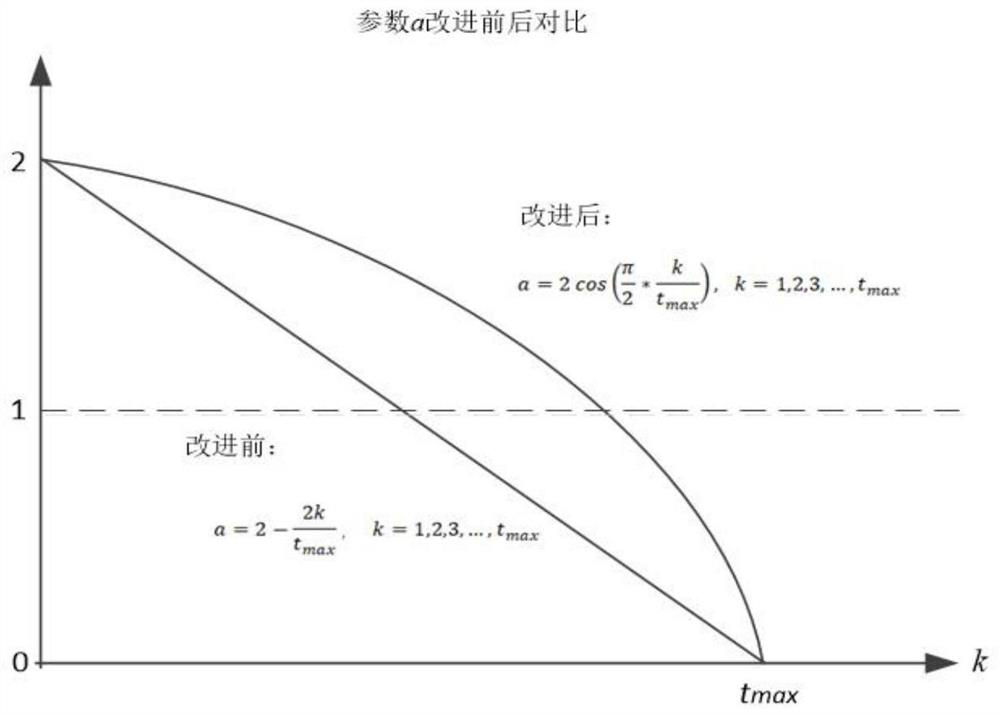

[0118] S2, setting the execution parameters of the algorithm, the execution parameters include the previous number of iterations t=1, the maximum number of iterations t max , neighborhood search probability ε, neighborhood maximum search times s max , according to the nonlinearly reduced iteration param...

Embodiment 2

[0212] In the second aspect, the present invention also provides a production and maintenance scheduling system based on the improved gray wolf algorithm, the system comprising:

[0213] A processing unit for performing the following steps:

[0214] S1. Input parameters of the initialization algorithm, including the number n of workpieces and the delivery date of workpieces d j , the unit time delay cost w of the workpiece j , unit production cost c l , the time required for a preventive maintenance activity t p and cost c p , the time required for a corrective maintenance activity t r and cost c r , the virtual service age at the initial moment of the machine and the number of preventive maintenance experienced m;

[0215] S2, setting the execution parameters of the algorithm, the execution parameters include the previous number of iterations t=1, the maximum number of iterations t max , neighborhood search probability ε, neighborhood maximum search times s max , ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com