Shoeprint hole and insert feature detection and description method

A feature detection and embedding technology, which is applied in image data processing, instruments, calculations, etc., can solve problems such as complex background, large amount of interference information, and large changes in shoe print image patterns, achieving high frequency of occurrence, avoiding interference areas, The effect of guaranteed detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

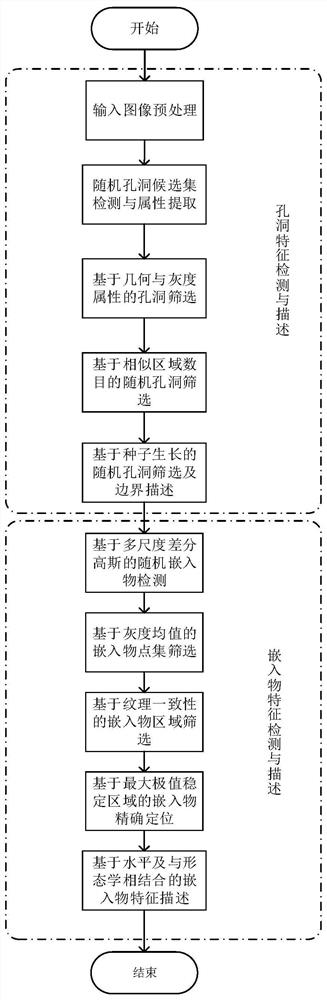

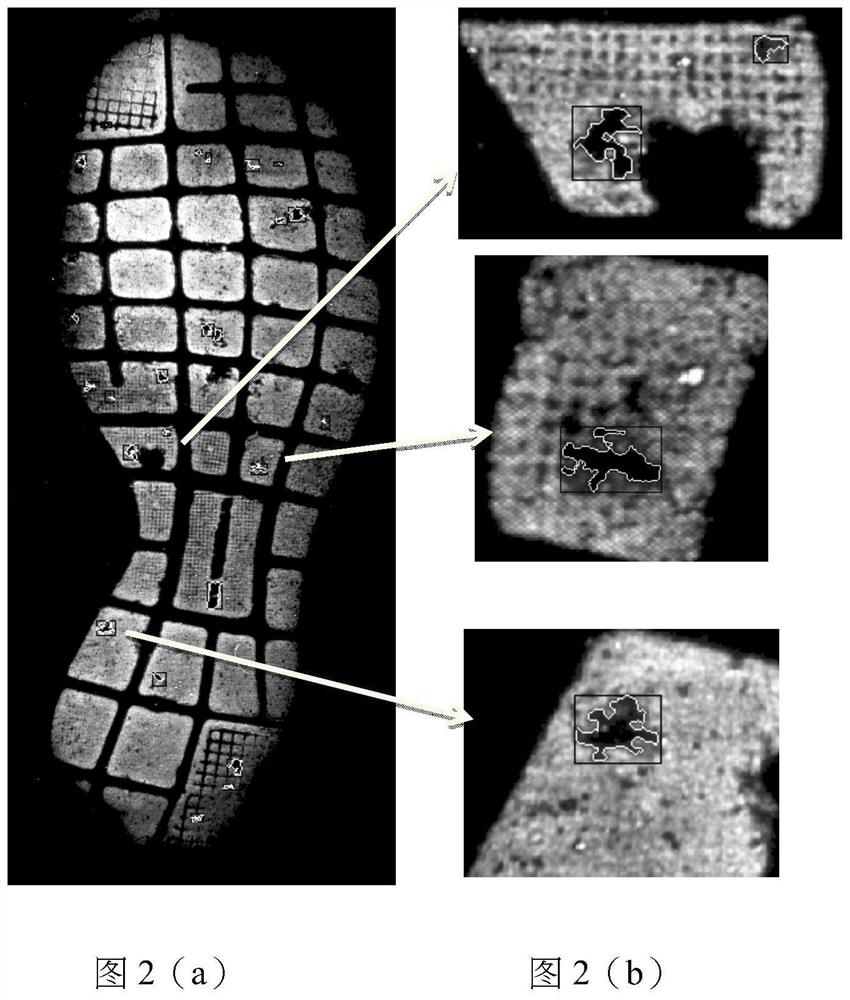

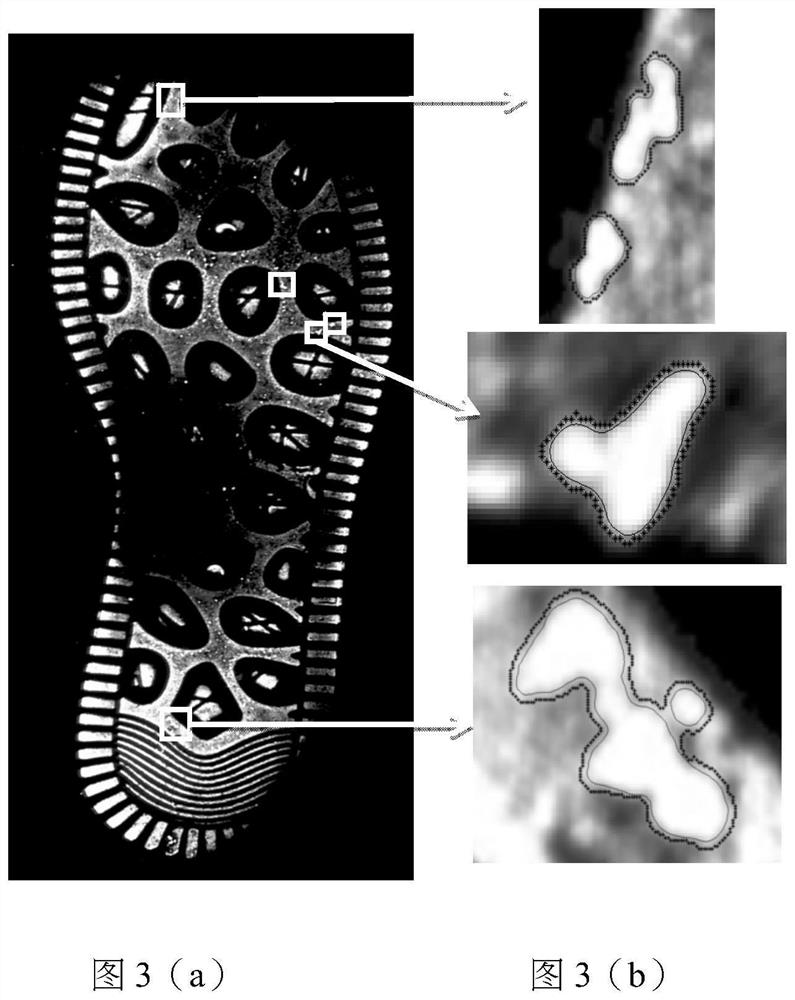

[0050] Such as figure 1 A method for detecting and describing the features of shoe print holes and embedded objects based on multi-level screening of the maximum extreme value stable region is shown, including two parts: hole detection and embedded object detection, and specifically includes the following steps:

[0051] The steps of hole detection and description are as follows:

[0052] S1: Obtain the hole candidate set and extract its attribute information:

[0053] Reduce the image to be detected to half of its original size, and perform median filtering on the reduced image to obtain the preprocessed shoe print image I;

[0054] Perform maximum extremum stable region detection (MSER) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com