Structure applied to common-caliber antenna body test

A common aperture, antenna technology, applied in the field of mobile communication, can solve the problems of strong inductance benefit impedance mismatch, long feeding path, inability to realize bottom feeding test scheme, etc., to avoid impedance mismatch and reduce loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

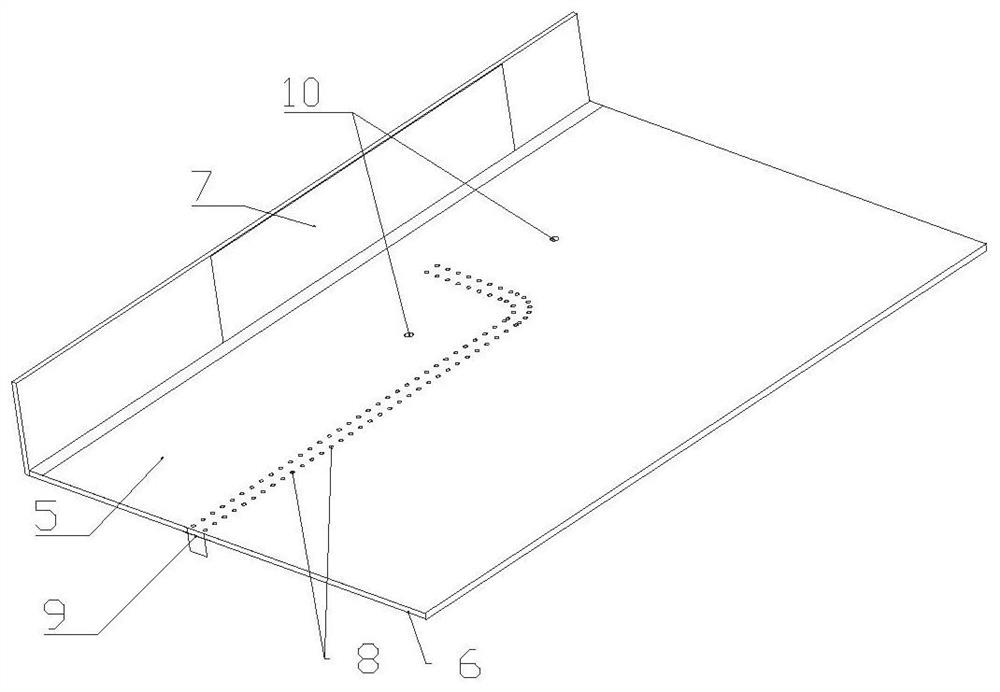

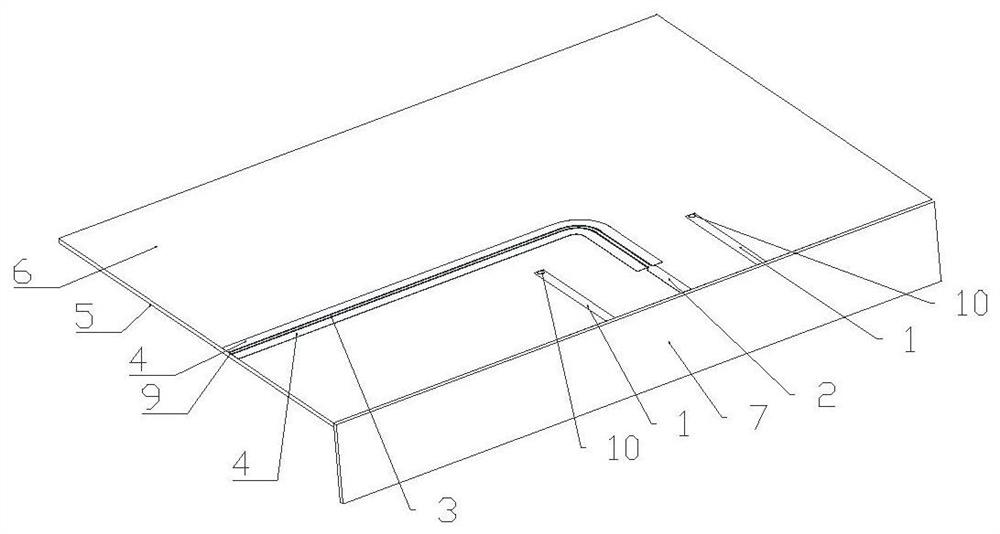

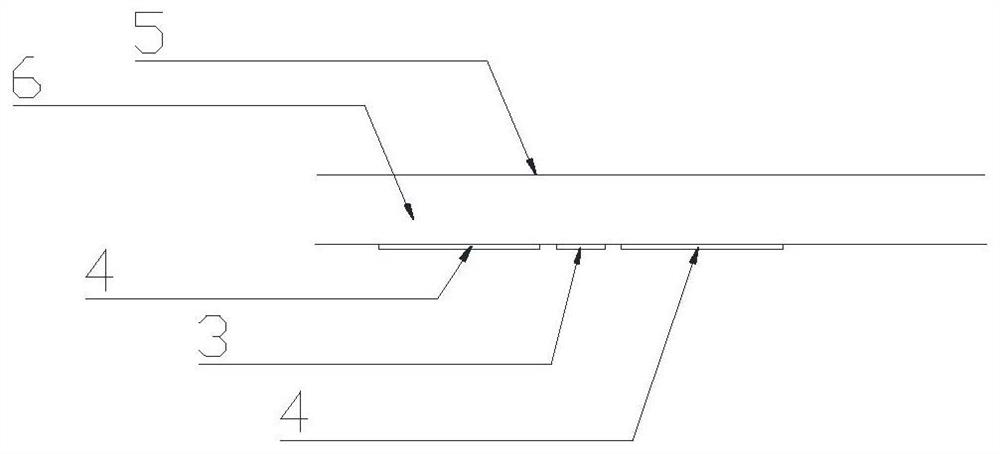

[0037] see figure 1 , figure 2 as well as image 3 , a structure applied to the common-aperture antenna body test, including a common-aperture antenna body 7, a feeding component group, a dielectric plate 6 and a metal floor 5; the common-aperture antenna body 7 includes at least one Sub-6GHz antenna and at least one Millimeter wave antenna; the feeding component group includes first feeding components whose number matches the number of Sub-6GHz antennas, and second feeding components whose number matches the number of millimeter wave antennas; the first feeding component is provided with a second A port 10 and the first microstrip line 1, the first port 10 feeds power to the Sub-6GHz antenna through the first microstrip line 1; the second feeding part is provided with a microstrip group, two A group of metal columns and a second port 9; the microstrip group is composed of a second microstrip line 2, a third microstrip line 3 and two fourth microstrip lines 4; the dielectri...

Embodiment 2

[0040] On the basis of the above structure, the distance from the first port 10 to the center of the common-aperture antenna body 7 is less than 0.5 times the distance from the second port 9 to the center of the common-aperture antenna body 7 .

[0041] Set the feed port of the Sub-6GHz antenna close to the common-aperture antenna body 7, and set the feed port of the millimeter-wave antenna away from the common-aperture antenna body 7, so that the feed ports of the two different frequency bands are far apart , to avoid signal interference between ports.

Embodiment 3

[0043] On the basis of the above structure, the length of the third microstrip line 3 is greater than twice the length of the second microstrip line 2 . When the length of the second microstrip line 2 is far less than the length of the third microstrip line 3 (that is, when the total length of the second microstrip line 2 and the third microstrip line 3 is constant, the coplanar waveguide transmission line is as long as possible), reducing The better the loss effect when the millimeter-wave antenna is fed, the better it is to ensure that the feed ports of two different frequency bands are far away from each other and do not interfere with each other.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap