Electronic cigarette atomizer and electronic cigarette

An electronic cigarette atomizer and atomizer technology, which is applied in the field of electronic cigarettes, can solve problems such as burnt smell, burnt oil-guiding cotton, and bad suction experience, and achieve the effects of novel structure, avoiding burnt, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

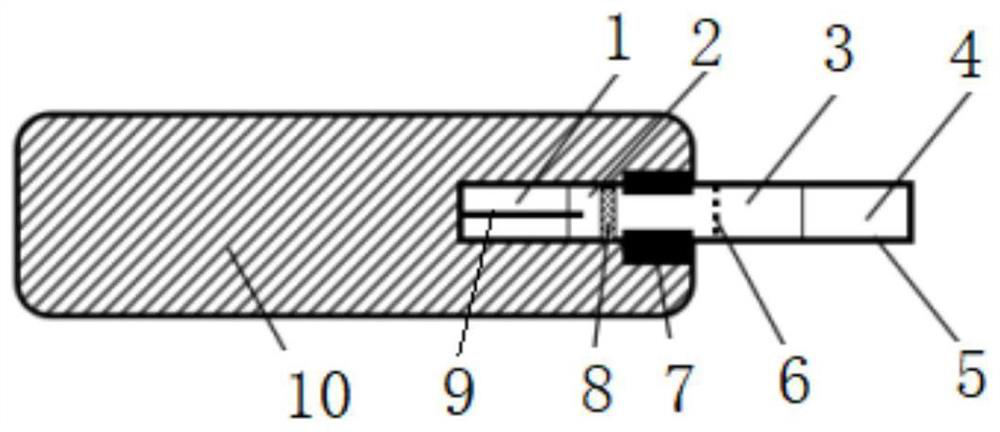

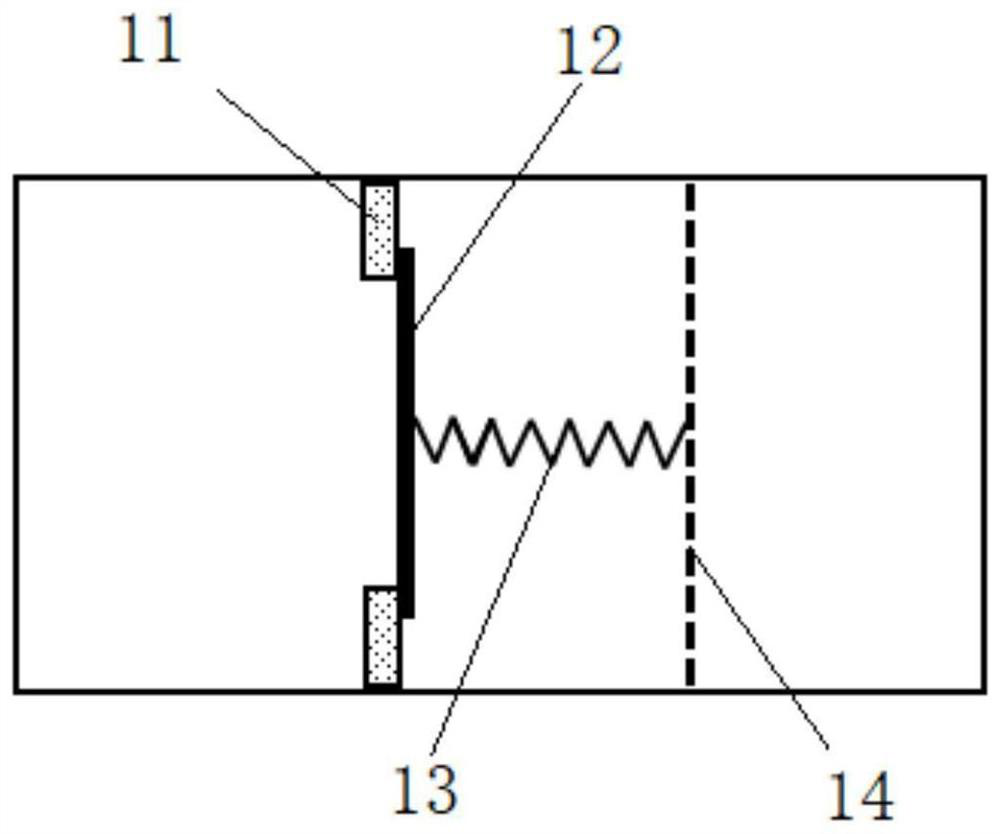

[0021] like figure 1 and 2 As shown, an electronic cigarette atomizer includes: an atomizer body 5, in which an oil storage area 1, an atomization area 2, a transfer area 3, and an inhalation area are sequentially arranged from one end to the other end of the atomizer body 5 4. The oil storage area 1 is sealed, and the oil storage area 1 and the atomization area 2 are connected through several atomization cores 9. The oil storage area 1 and the atomization area 2 of the atomizer body 5 are made of heat-conducting materials Made, on the side wall of the transfer area 3 is provided with an air intake hole 6 .

[0022] In some embodiments, the atomizing core 9 is made of a material having a capillary action and / or a siphon action. The atomizing core 9, which can be made by capillary action and / or siphon action, transfers the e-liquid from the oil storage area 1 to the atomizing area 2, and the material includes but not limited to cotton thread or polypropylene.

[0023] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com