Rice dividing unit for three-section germ-remained rice and germ-remained rice cutting machine using same

A technology of leaving germ rice and cutting rice, which is applied in the fields of application, grain processing, agriculture, etc., can solve the problem of low efficiency of rice grinding, and achieve the effect of improving the efficiency of cutting rice, reducing the height and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

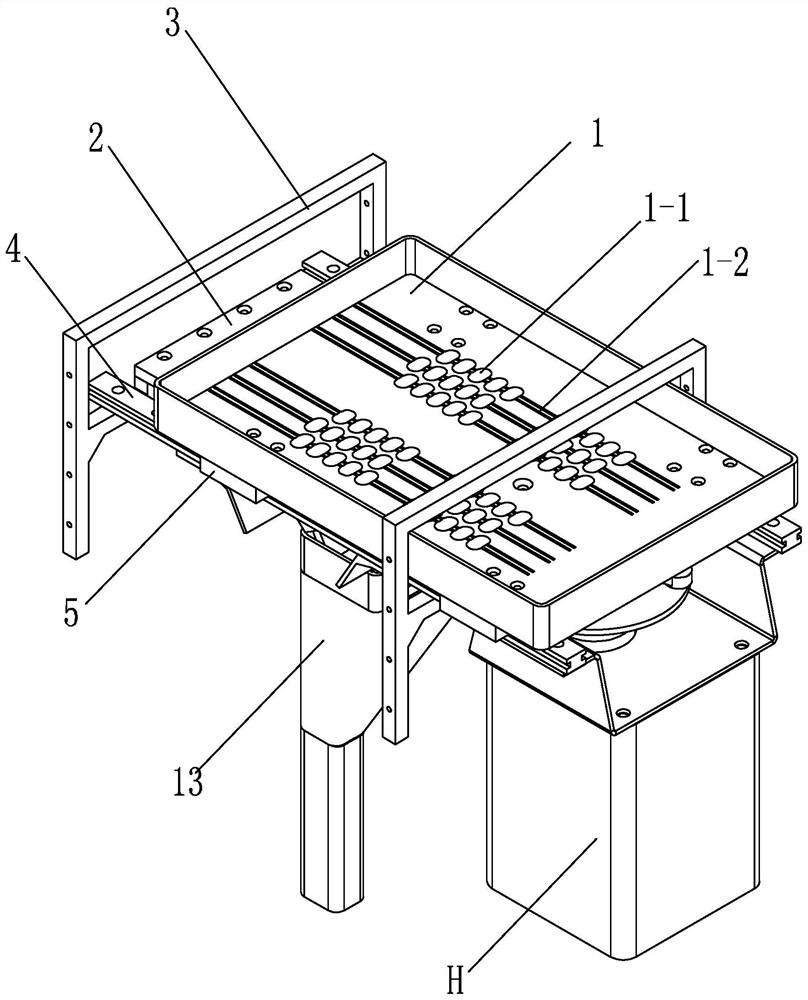

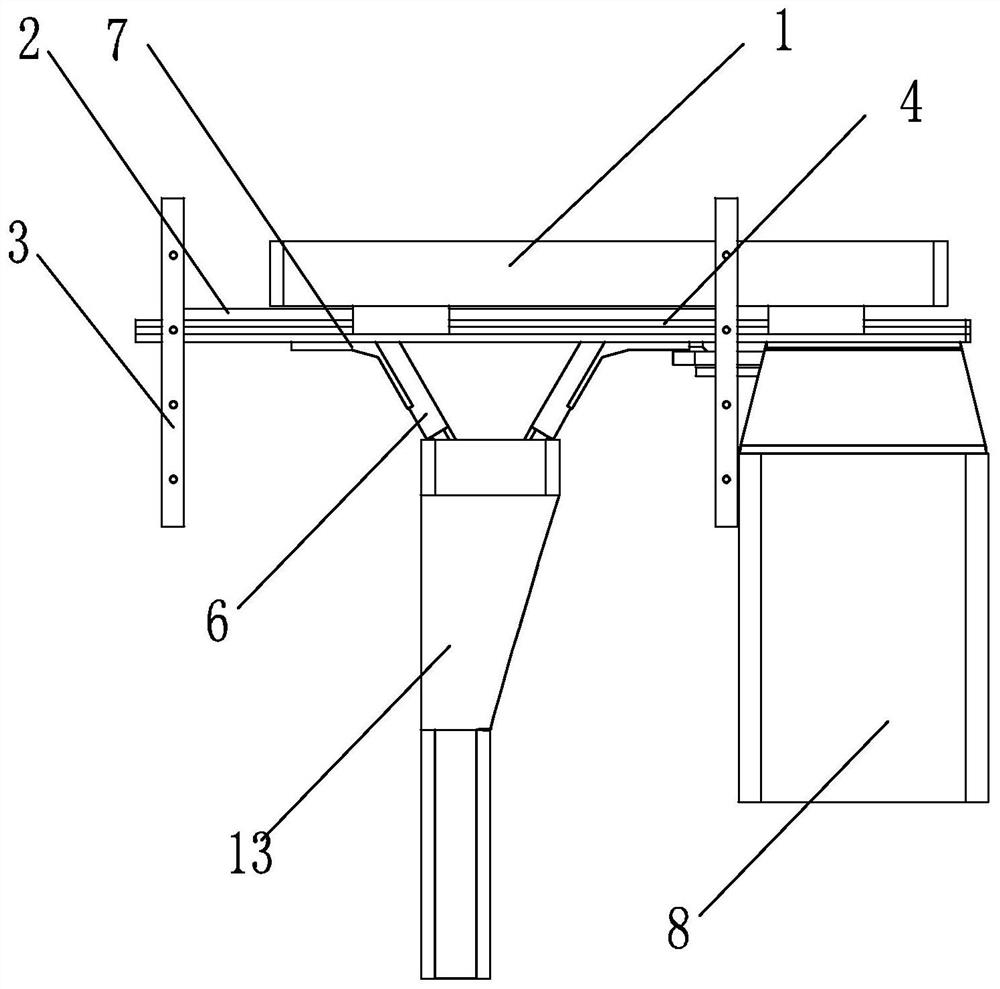

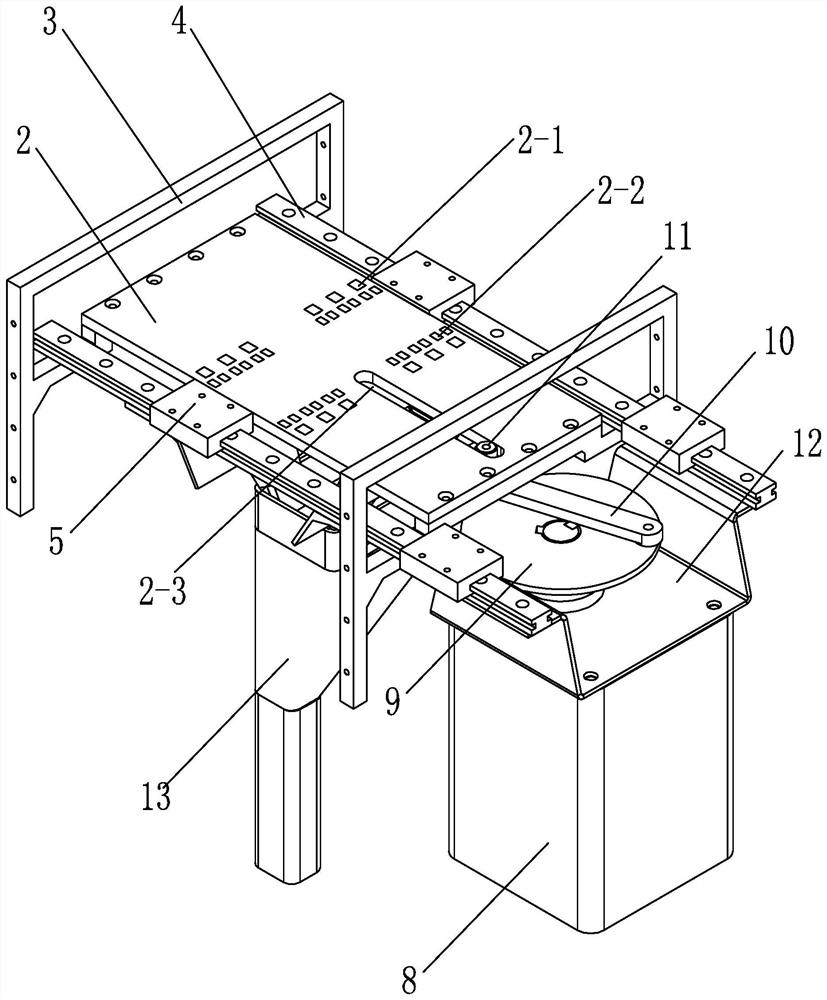

[0015] Specific implementation mode one: combine Figure 1 to Figure 5 Description of this embodiment This embodiment includes a rice falling board 1 and a rice board 2, and it also includes a middle section slideway 6; the rice falling board 1 reciprocates horizontally and is slidably installed on the rice board 2; Multiple rows of rice-dropping units, each row of rice-dropping units has a plurality of rice-dropping holes 1-1, and the rice-dropping holes 1-1 on two adjacent rows of rice-dropping units are arranged in a staggered position; the Tommy board 2 is symmetrical There are two rows of decimeter units, and each column of decimeter units includes a middle section of the meter hole 2-1 and two meter tip drop hole 2-2 symmetrically arranged on the left and right, and the middle section of the meter hole 2-1 and two meter tips The rice falling holes 2-2 are arranged in the shape of "product", and the lower end of the rice tip falling rice holes 2-2 of each row of decimeter...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination image 3 To describe this embodiment, the rice hole 2-1 in the middle section of this embodiment is a rectangular hole. Such setting is convenient to provide enough space for the middle section of the rice grains to fall, and effectively avoids the jamming problem caused by the inertial force of the rice grains. Other compositions and connections are the same as in the first embodiment.

[0020] The strip-shaped middle section rice hole 2-1 mentioned in this embodiment is a rectangular hole, and the long side of the rectangular hole is parallel to the long side of the tomi board.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination image 3 Describe this embodiment, the tomi board 2 of this embodiment is provided with elongated holes 2-3 along its length direction. In this way, the elongated hole mainly provides a space for the pin shaft 11 in the drive assembly to slide linearly, and then drives the rice falling board to reciprocate. Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com