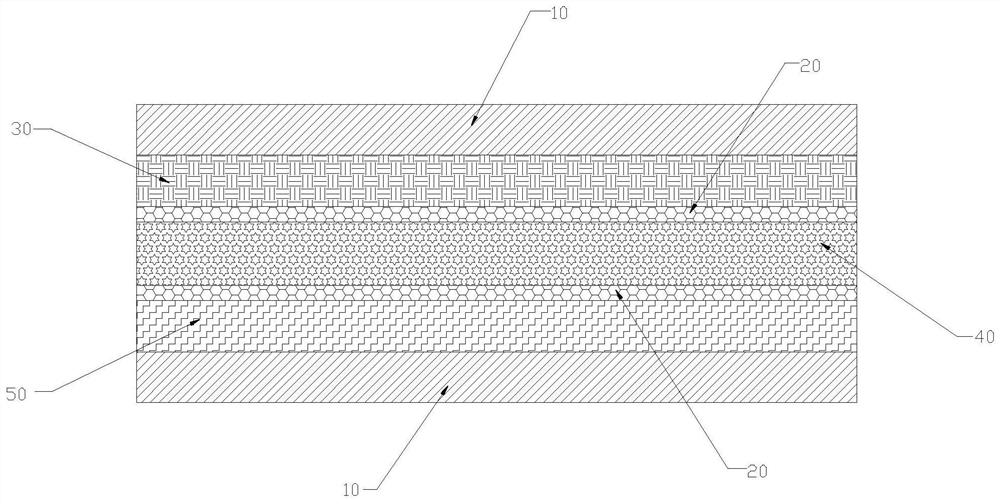

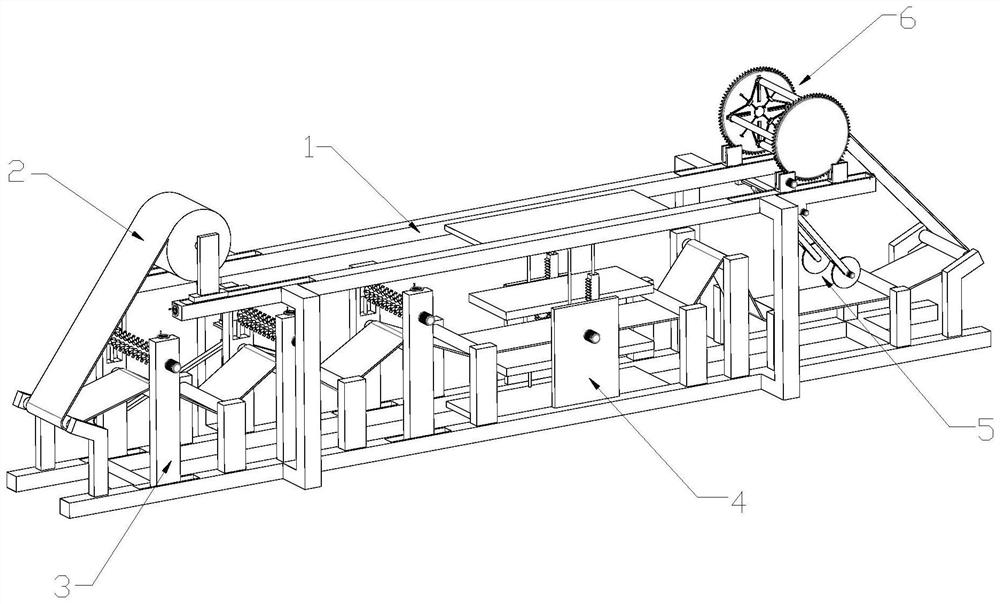

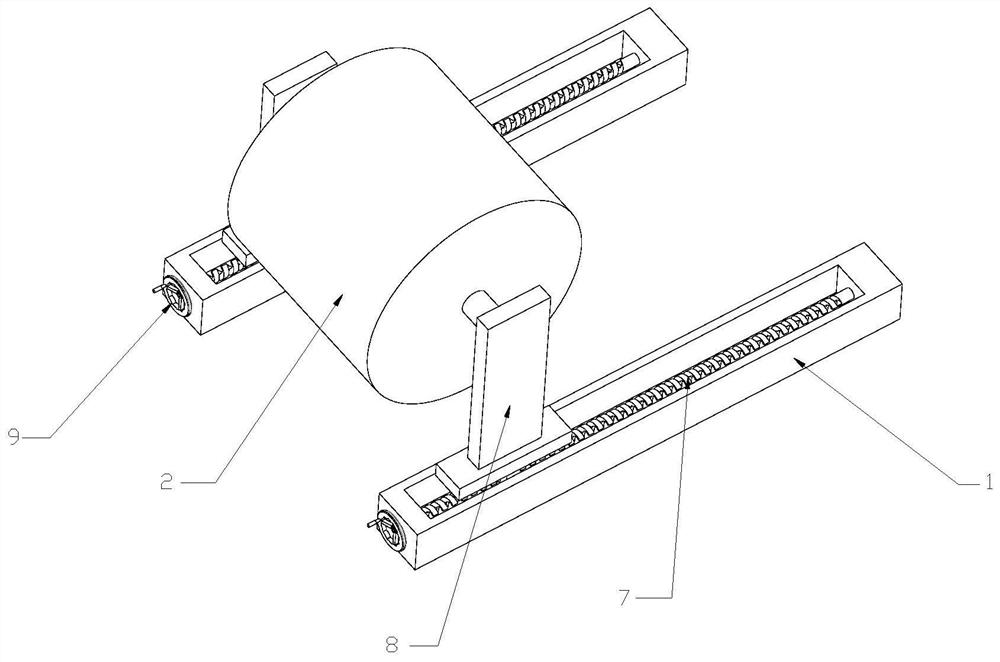

A kind of anti-mosquito high-elastic fabric and its production process and device

A production device and anti-mosquito technology, applied in lamination devices, layered products, fabric surface trimming, etc., can solve problems such as fabric damage, and achieve the effects of clear processing levels, strong practicability, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A kind of production technology of anti-mosquito high elastic fabric, comprises the steps:

[0081] S1. Select high-quality raw materials according to the mass ratio, including 2 kilograms of borneol, 1 kilogram of musk powder, 4 kilograms of bamboo vinegar, 25 kilograms of non-woven fabrics, 18 kilograms of nylon silk, 8 kilograms of polyurethane, 12 kilograms of cyanoacrylate, and 35 kilograms of silk. kg, 60 kg of cotton wool, 28 kg of polyethylene terephthalate and 6 kg of ethylene glycol;

[0082] S2. Wash and dry the selected borneol, control the drying temperature to 80° C., and the water content after drying is 5%, and then draw into filaments after high-temperature melting;

[0083] S3, entangle the borneol silk and the nylon thread to form a composite fiber, then place it and the musk powder in a cooking pot and add water to steam and fumigate, control the mass ratio of water and borneol silk to be 2:1, and control the cooking temperature to be 2:1. 60°C, the...

Embodiment 2

[0092] S1. Select high-quality raw materials according to mass ratio, including 4 kilograms of borneol, 2 kilograms of musk powder, 6 kilograms of bamboo vinegar, 35 kilograms of non-woven fabrics, 26 kilograms of nylon silk, 10 kilograms of polyurethane, 13 kilograms of cyanoacrylate, and 50 kilograms of silk kg, cotton batting 80 kg, polyethylene terephthalate 36 kg and ethylene glycol 9 kg;

[0093] S2. Wash and dry the selected borneol, control the drying temperature to 85° C., and the moisture content after drying is 4%, and then draw into filaments after high-temperature melting;

[0094]S3, borneol silk and nylon thread are entwined to form composite fiber, then it and musk powder are placed in cooking pot and add water and carry out steaming, control the mass ratio of water and borneol silk to be 1:1, control cooking temperature is 50°C, the cooking time is 70min, and then it is woven with non-woven fabric to form a composite fabric, and the thickness is controlled to ...

Embodiment 3

[0103] S1. Select high-quality raw materials according to mass ratio, including 3 kilograms of borneol, 1.5 kilograms of musk powder, 5 kilograms of bamboo vinegar, 30 kilograms of non-woven fabrics, 22 kilograms of nylon silk, 9 kilograms of polyurethane, 12.5 kilograms of cyanoacrylate, and 43 kilograms of silk kg, cotton batting 70 kg, polyethylene terephthalate 32 kg and ethylene glycol 8 kg;

[0104] S2. Wash and dry the selected borneol, control the drying temperature to 75° C., and the moisture content after drying is 4%, and then draw into filaments after high-temperature melting;

[0105] S3, borneol silk and nylon thread are entwined to form composite fiber, then it and musk powder are placed in cooking pot and add water and carry out steaming, control the mass ratio of water and borneol silk to be 1:1, control cooking temperature is 55°C, the cooking time is 65min, and then it is woven with non-woven fabric to form a composite fabric, and the thickness is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com