A kind of scrap verification and recovery device for electronic experimental parts and its use method

A recycler and parts technology, applied in the field of scrap verification recycler for electronic experimental parts, can solve the problems of weak pressure resistance, affecting the health of staff, dust flying, etc., so as to reduce the impact on physical health and reduce the difficulty of cleaning , reduce the effect of flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

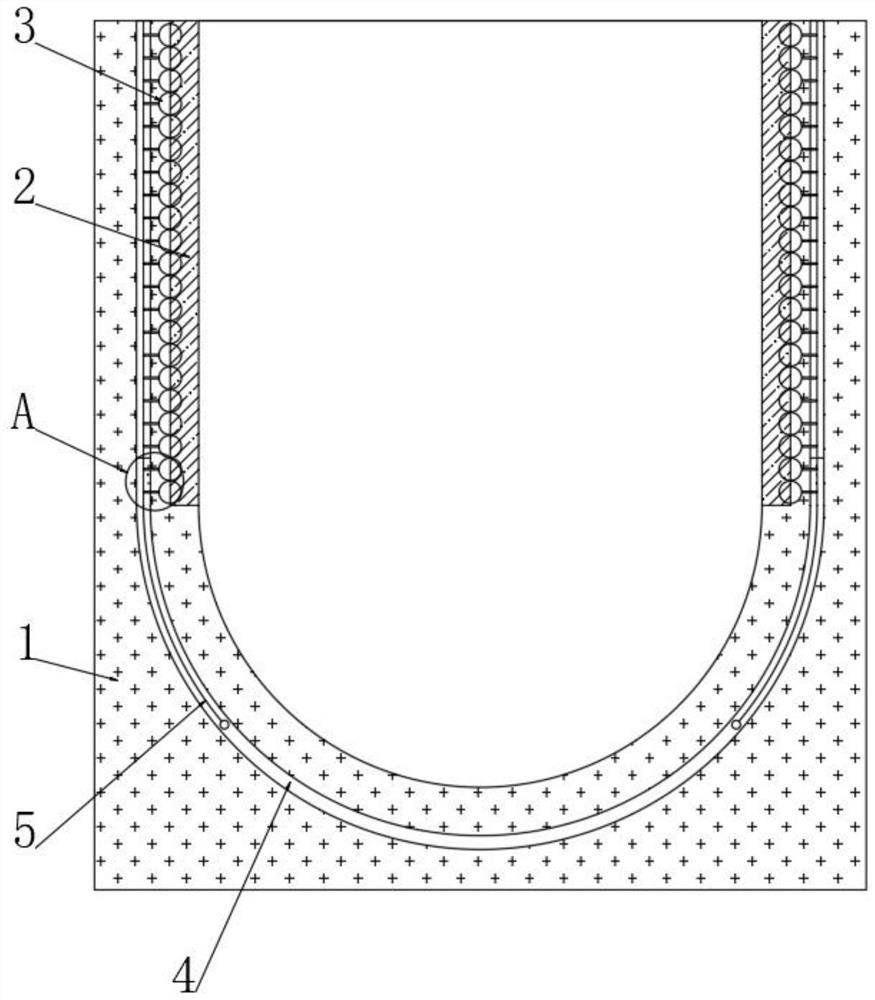

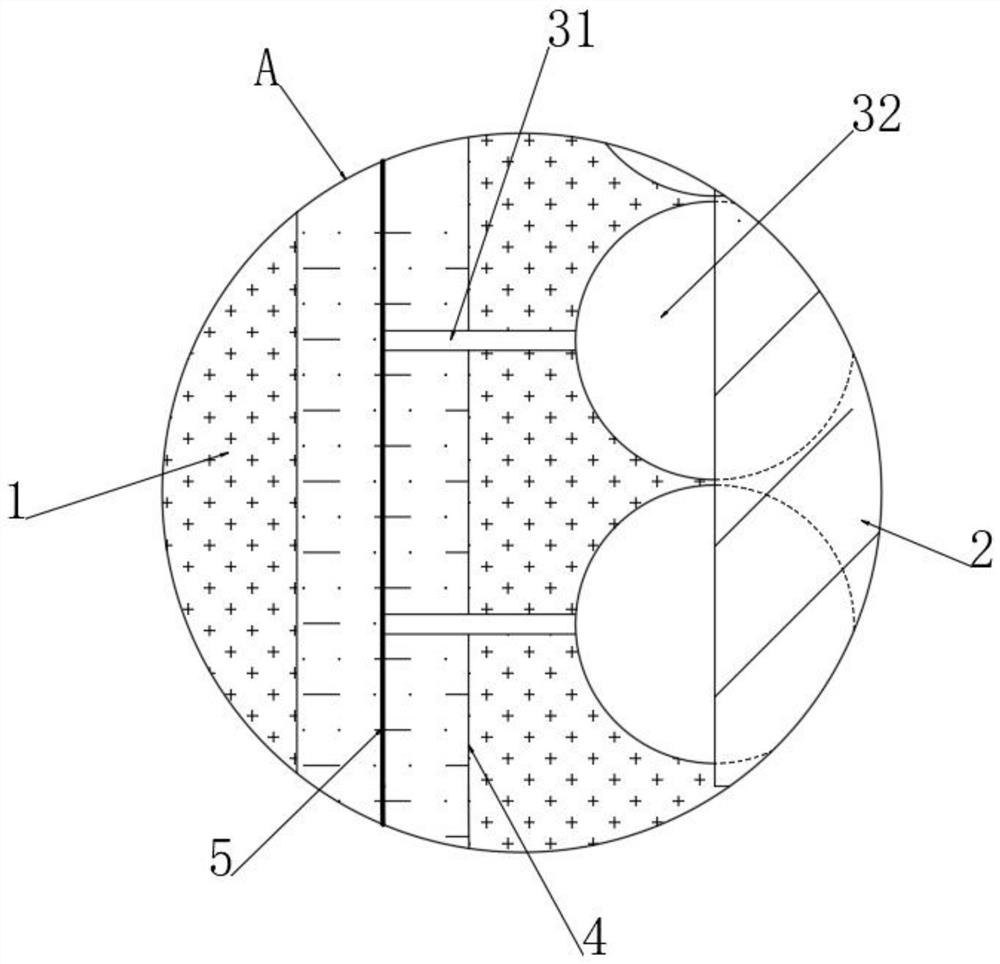

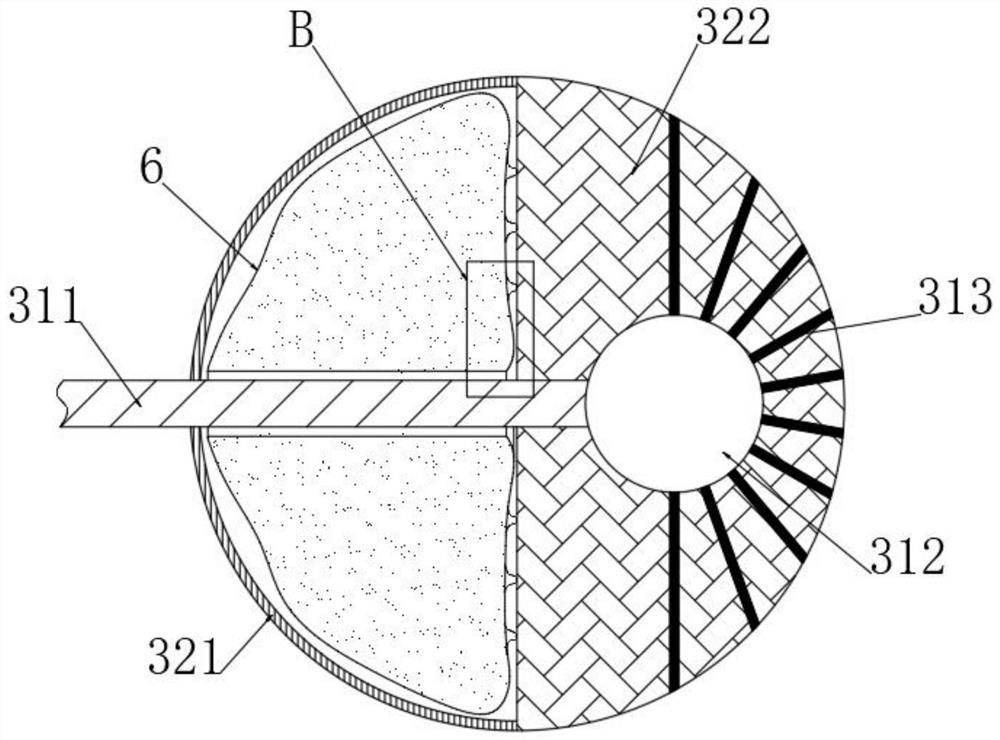

[0043] see figure 1 , an electronic experimental parts scrap verification recycler, comprising a recycler body 1, the recycler body 1 is made of a transparent low thermal conductivity material, the inner wall of the recycler body 1 is a spherical shape concave inward, and the inner wall of the recycler body 1 is first After polishing, it is coated with a nano dust-proof coating, so that the inner wall of the recycler body 1 has no obvious edges and corners, which is convenient for the cleaning of the device after use and reduces the difficulty of cleaning. Inside the groove 4 is placed a water-conducting cotton thread pendant 5, the water-conducting cotton thread pendant 5 is made of water-absorbing material, and the upper end of the water-conducting cotton thread pendant 5 is thickened, and the upper end of the water-conducting cotton thread pendant 5 is mainly the lower end of the vacuum sticker The diameter of the thickened part is 2-3 times the diameter of the unbolded par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com