Air inlet position adjusting device

A technology for regulating devices and tuyere, which is applied in grinding/polishing safety devices, metal processing equipment, grinding/polishing equipment, etc., and can solve problems such as accumulation of suction debris, unsatisfactory absorption effect, random flying accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

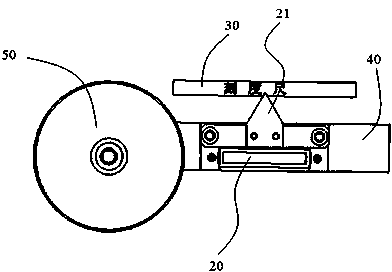

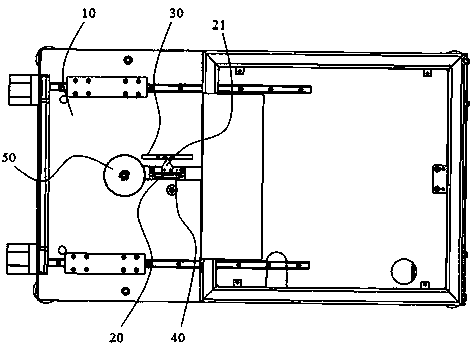

[0021] Please refer to figure 1 with figure 2 As shown, it is a schematic structural diagram of a tuyere position adjustment device of the present invention, including: a workbench 10 for workpiece processing; an air inlet 20 for absorbing fine chips generated during the machining process, which is connected with a vacuum cleaner (not shown) Connection; the scale 30 is located on the surface of the workbench 10 and is located on one side of the air inlet 20, as the adjustment standard of the air inlet device; the pointer 21 is fixed on the side of the air inlet 20 and points to the air inlet 20. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com