Gold-spraying dust absorption device for thin-film capacitor

A technology of absorbing devices and film capacitors, which is applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of unfavorable metal powder recycling, difficulty in bag cleaning, and high power consumption, and achieve simple structure, good effect, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

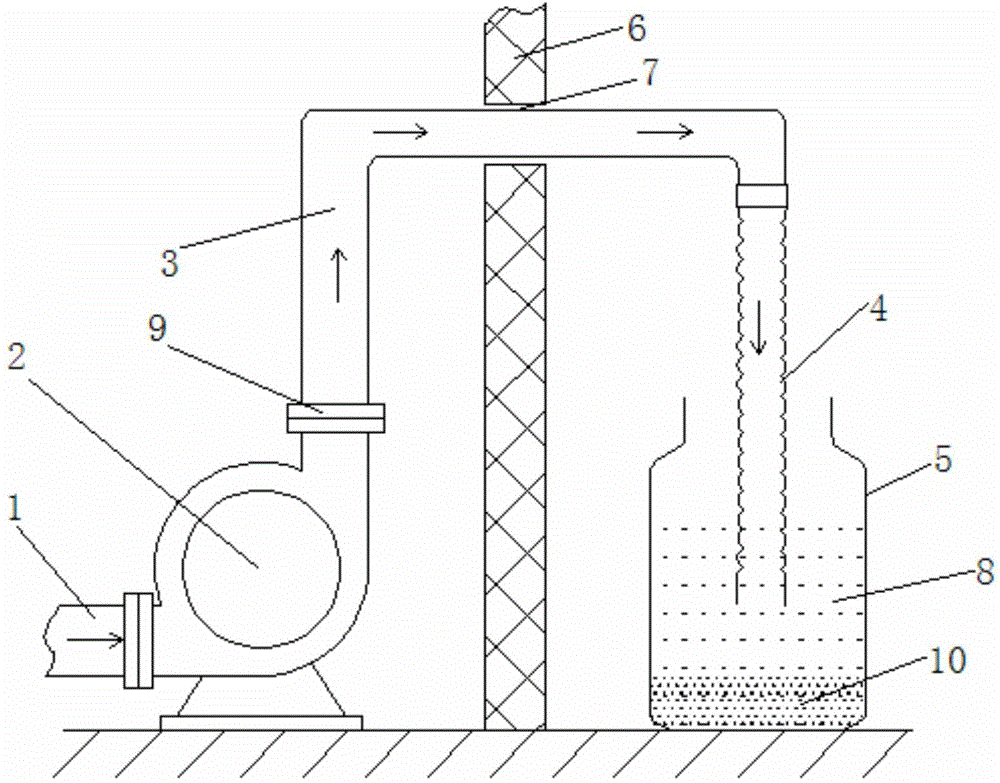

[0012] Referring to the accompanying drawings, a thin-film capacitance gold-sprayed dust absorbing device includes an input induced-air steel pipe 1, an induced-air fan 2, an output induced-air steel pipe 3, a plastic bellows 4 and a plastic bucket 5, and the input-induced-air steel pipe 1 and the induced-air 2 connection, the induced draft fan 2 is connected to the output induced air steel pipe 3, the output induced air steel pipe 3 extends to the outside through the wall hole 7 of the wall 6, and is connected to one end of the plastic corrugated pipe 4, and the other end of the plastic corrugated pipe 4 is placed in a plastic bucket 5 Inside, tap water 8 is housed in the plastic bucket 5, and the other end of the plastic corrugated pipe 4 is placed below the water surface, and the connection between the input induced-air steel pipe 1 and the induced-induction fan 2, the connection between the induced-induction fan 2 and the output induced-air steel pipe 3 and Output air-intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com