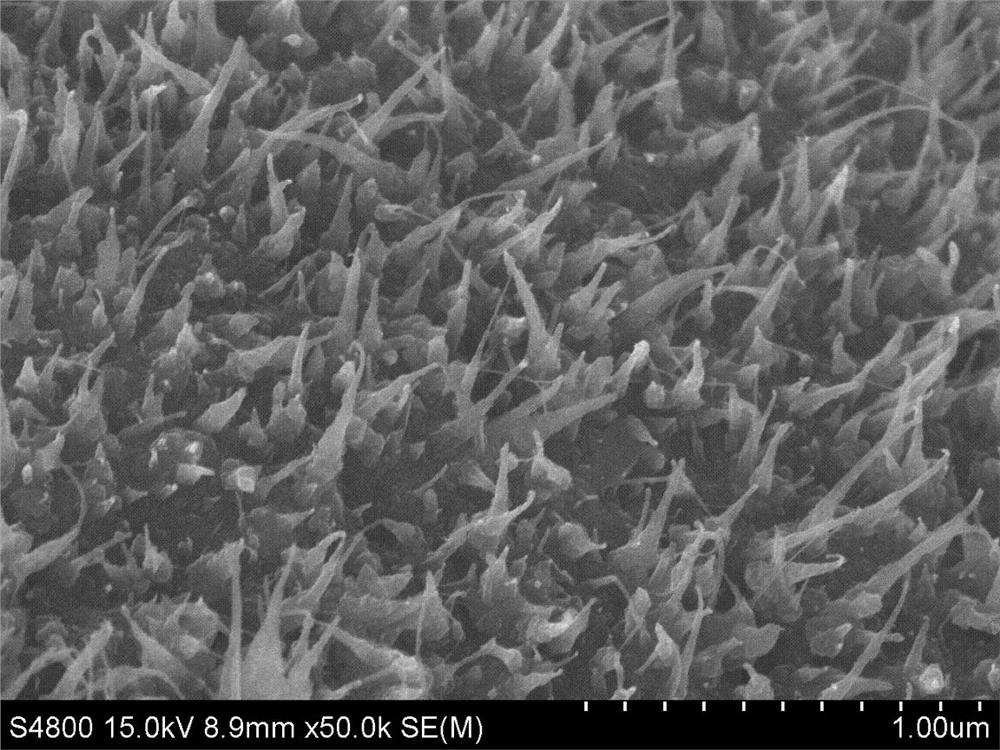

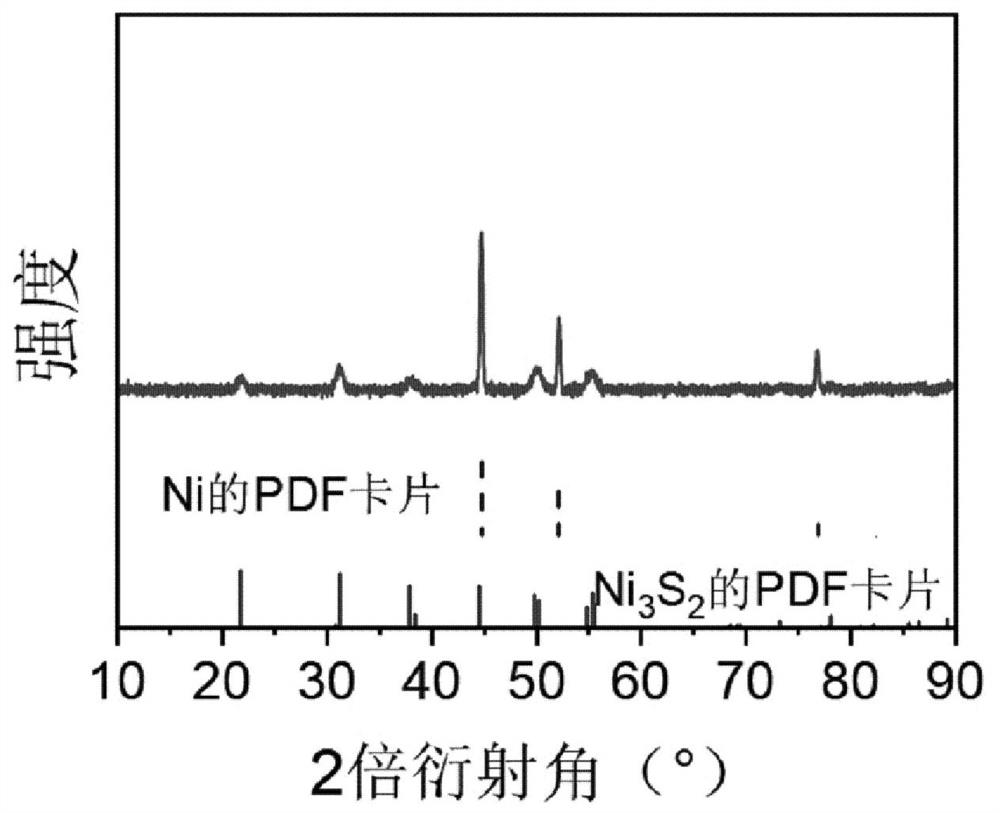

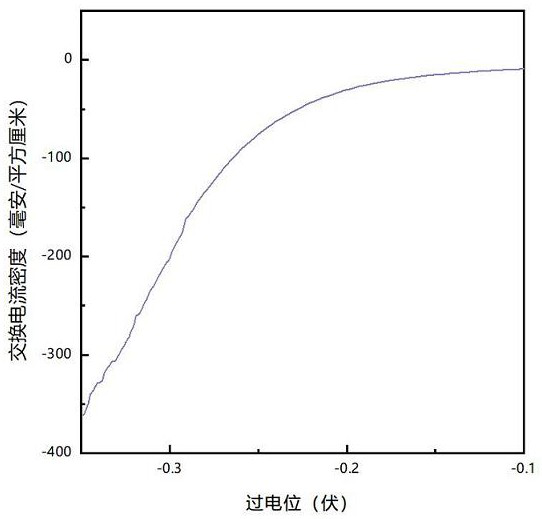

Needle-shaped Se-doped Ni3S2 and preparation method thereof

A needle-shaped and nano-needle technology, applied in the field of needle-shaped Se-doped Ni3S2 and its preparation, can solve the problems of high overpotential and Tafel slope, less active site loading, and mediocre morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be described in detail below in conjunction with specific embodiments.

[0016] The specific steps of the present embodiment are as follows: cut out a piece of foamed nickel whose size is 1.5 by 0.5 square centimeters; immerse the cut foamed nickel in 12 moles per liter of concentrated hydrochloric acid for ultrasonic cleaning for ten minutes, then immerse in acetone for five minutes, Then immerse in ethanol and ultrasonically clean for five minutes; put the foamed nickel after cleaning into a vacuum drying oven and dry for 30 minutes at a temperature of 40 degrees Celsius; weigh 0.5 mmol of selenium powder, 3 mmol of NaBH 4 , put 20 ml of deionized water into a beaker, and use a temperature-controllable magnetic stirrer to control the temperature at 50 degrees Celsius and stir until the selenium powder is dissolved; add 4 mmol of CH to the beaker 4 N 2 S, 0.5 millimoles of urea and 0.1 grams of PVP, add 20 milliliters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com