A kind of anti-cut yarn and preparation method thereof

A technology of anti-cutting and yarn, which is applied in the direction of yarn, rayon manufacturing, textile and paper making, etc. It can solve the problems of high cost and non-conformity with the production process, achieve good skin-core uniformity, save raw material costs, and shorten the process cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

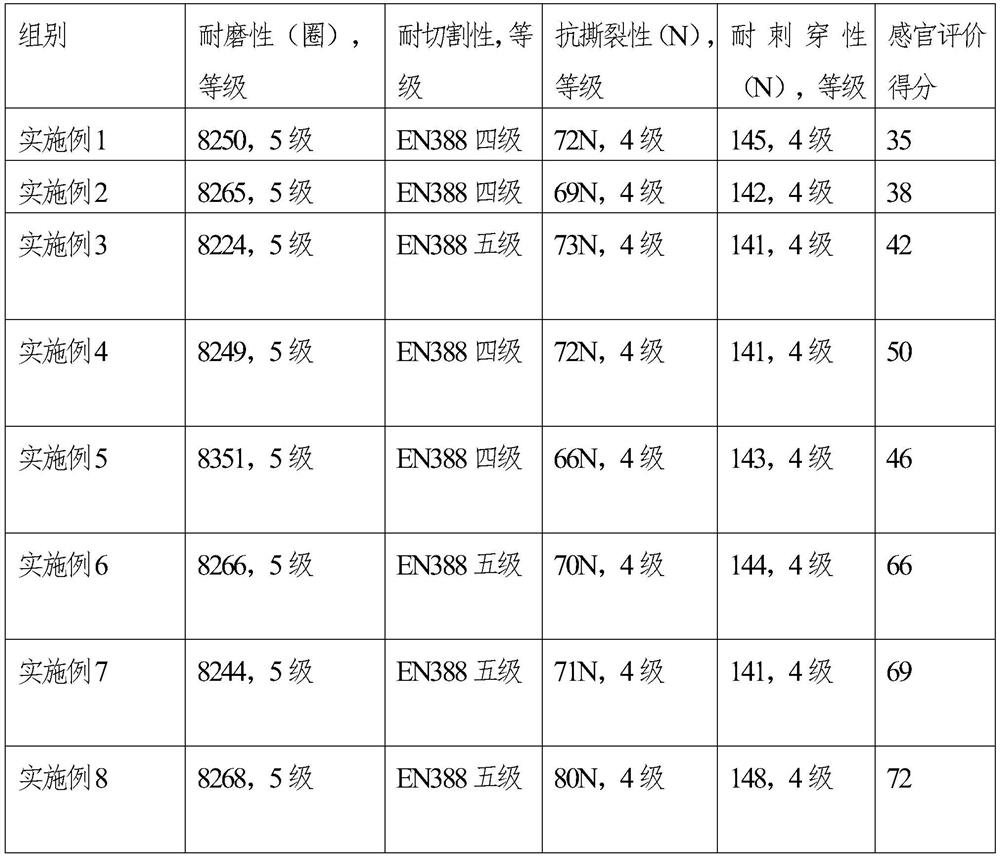

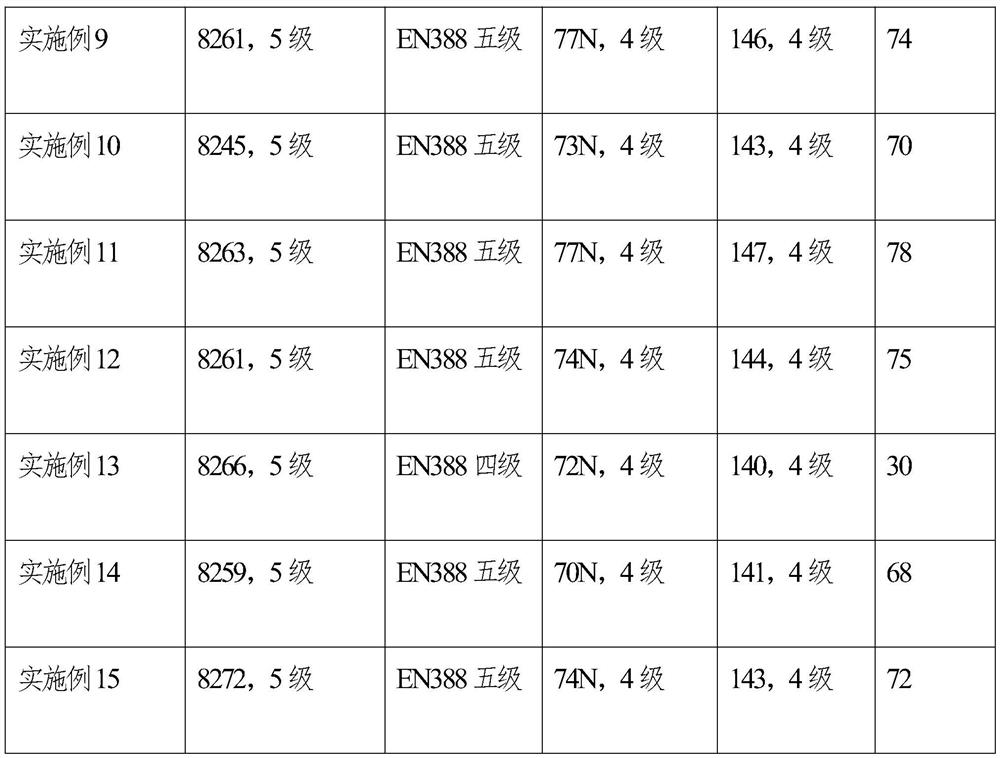

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing a cut-resistant yarn, including an outer covering wire and a core wire.

[0038] Outer wire: The outer wire is an ultra-high molecular weight polyethylene fiber filament with a molecular weight of 400,000-800,000 and a diameter of 400D. Core thread: 200dtex polyester semi-finished yarn POY, containing 4.5wt% boron nitride powder with a particle size of 0.01-1 micron. The core wire is stretched and elasticized by rollers, the setting temperature is 170°C, the stretching ratio is 1.7, the outer covering wire is twisted and wrapped on the outside of the core wire, and twisted into strands to obtain a cut-resistant yarn.

[0039] The mass components of the prepared cut-resistant yarn are: polyester semi-finished yarn POY: 40wt%; ultra-high molecular weight polyethylene fiber filament: 60wt%.

Embodiment 2

[0041] This embodiment provides a method for preparing a cut-resistant yarn, including an outer covering wire and a core wire.

[0042] Outer wire: The outer wire is an ultra-high molecular weight polyethylene fiber filament with a molecular weight of 400,000-800,000 and a diameter of 400D. Core thread: 200dtex polyester semi-finished yarn POY, containing 6wt% boron nitride powder with a particle size of 0.01-1 micron. Use rollers to stretch and elasticize the core wire. The setting temperature is 170°C and the stretching ratio is 1.7. Twisting and wrapping the outer covering wire on the outside of the core wire, twisting into a strand and drawing at the same time, spraying air pressure through the grid nozzle The compressed air of 1.5-3.5Pa is used to prepare cut-resistant empty yarn. Air charter air pressure is 2.5Pa compressed air.

[0043] The mass components of the prepared cut-resistant yarn are: polyester semi-finished yarn POY: 40wt%; ultra-high molecular weight poly...

Embodiment 3

[0045] This embodiment provides a method for preparing a cut-resistant yarn, including an outer covering wire and a core wire.

[0046] Outer wire: The outer wire is an ultra-high molecular weight polyethylene fiber filament with a molecular weight of 400,000-800,000 and a diameter of 400D.

[0047] Core thread: 200dtex polyester semi-finished silk POY and 140D spandex thread parallel as the core thread. Wherein, the polyester semi-finished yarn POY contains 5 wt% of boron nitride powder with a particle size of 0.01-1 micron. Two pairs of rollers are used to stretch, stretch and shape the core wire. The setting temperature is 160°C and the draw ratio is 1.8. The compressed air with a pressure of 1.5-3.5Pa is sprayed from the grid nozzle to prepare cut-resistant empty-packed yarn. Air charter air pressure is 2.5Pa compressed air.

[0048] The mass components of the cut-resistant yarn prepared are: polyester semi-finished yarn POY: 42wt%; spandex yarn: 26wt%; ultra-high molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com