Prefabricated structure and connecting joint of prefabricated structure

A technology for prefabricated assembly and connection of nodes, which is applied to building components, building structures, and building materials processing. , The effect of improving the quality of the building and the high precision of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

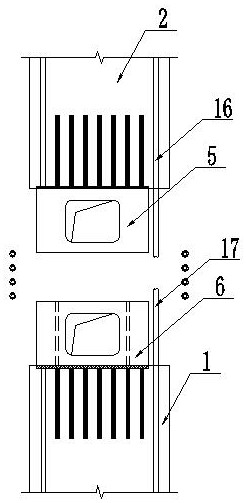

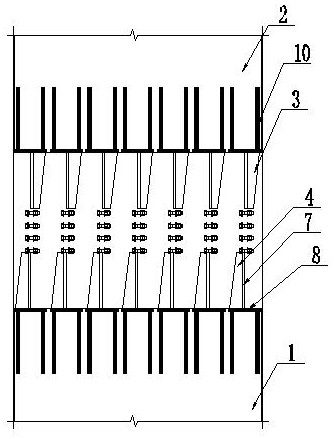

[0030] See figure 1 with figure 2 The embodiment of the present invention provides a connection node of a prefabricated assembled structure comprising a lower concrete structure 1 and an upper concrete prefabricating member 2 at the upper end of the lower concrete structure 1, and there is more vertical direction of the upper horizontal longitudinal direction of the upper concrete prefabricated member 2. A first connecting member 3, the top of the lower concrete structure 1 is provided with a plurality of second connecting members 4 in a horizontal longitudinal direction, and a plurality of first connectors 3 at the bottom of the upper concrete preform corresponding to the detachable fixed connection. Used to achieve a connection between the vertical direction between the upper concrete prefabricating member 2 and the lower concrete structure 1.

[0031] Further, the upper end of the upper concrete prefabricated member 2 is poured between the top of the lower concrete structure 1....

Embodiment 2

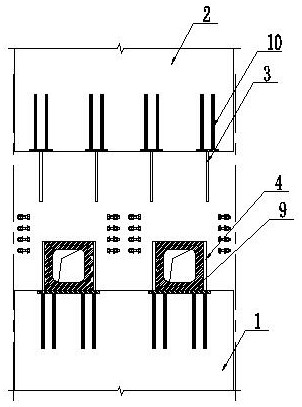

[0045] See image 3 The first connecting plate 5, the second connecting plate 6 of the present embodiment, each including a motherboard, and a bolt hole is spaced apart from the vertical direction; the first connecting plate 5, the second connecting plate 6 also includes a bottom plate. The bottom plate is horizontally, the motherboard is fixed vertically on the bottom plate; the embedded assembly includes a vertical anchor 10 extending in the vertical direction, the anchor being fixed to the bottom plate. The anchor is located on both sides of the bottom plate and the motherboard, respectively; a plurality of anchors are fixed on each bottom plate. The anchor is fixed vertically on the bottom plate. The bottom plate is embedded in the upper concrete prefabricating member 2 or the lower concrete structure 1. The secondary plate 9 is fixed between the two main boards disposed along the horizontal longitudinal interval in the motherboard of the first connector 3 or the second connect...

Embodiment 3

[0047] See Figure 1 to 6 In this embodiment, the present embodiment discloses a prefabricated assembled structure, including a plurality of upper concrete prefabricated members 2, which are sequentially stitched in the lower concrete structure 1, and adjacent two upper concrete prefabricated members 2 longitudinal splicing end surface卯 合 合,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

[0048] The lower concrete structure 1 of the present embodiment is a prefabricated concrete or cast-in-situ.

[0049] The lower concrete structure 1 may be sequentially stitched along the longitudinal direction of the plurality of lower concrete prefabricates, and the splicing structure can be the same as the splicing structure of the plurality of upper concrete prefabricated members 2.

[0050] Further, the longitudinal splicing end face of the two adjacent upper concrete preform members 2 should be fixedly fixed, and the third connecting plate 11 is provided with a bolt via, and the portrait of the two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com