Flow guide type inlet structure of drainage cooling section of heater and design method

A hydrophobic cooling and flow guiding technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as easy destruction of the equilibrium state, fluctuations in the water level of the heater, burst pipes, etc., to avoid vapor-liquid two-phase flow Phenomenon, enhance the suction capacity of siphon, improve the effect of siphon stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

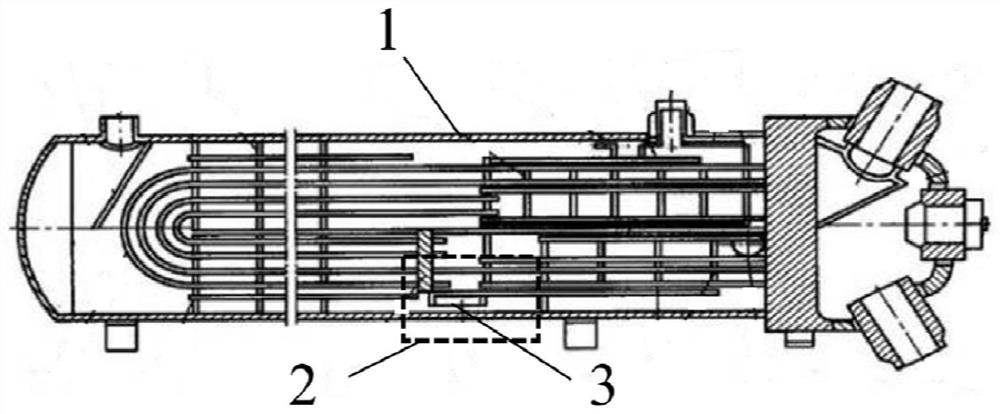

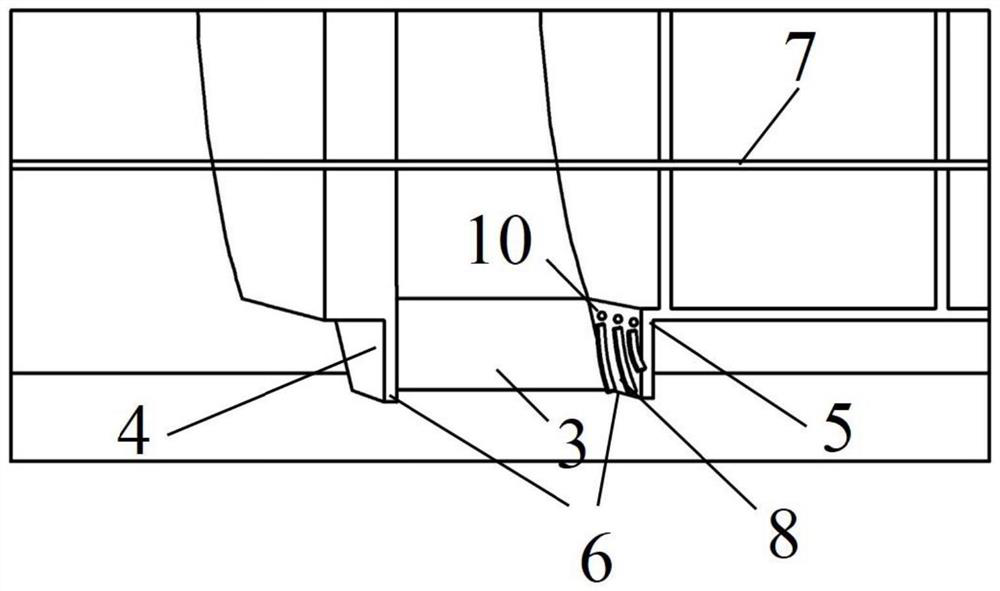

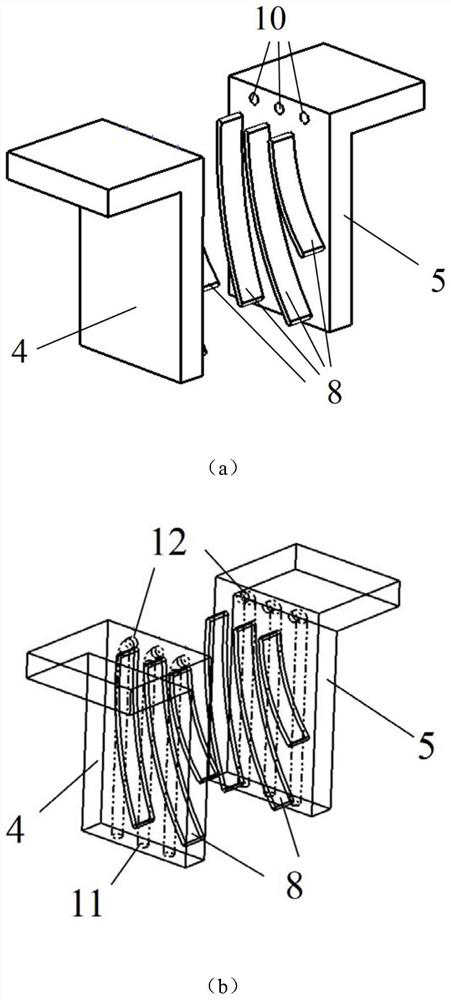

[0031] see Figure 1 to Figure 6 , a flow-guided heater hydrophobic cooling section inlet structure, including a number of guide vanes 8 arranged on the upstream hydrophobic cooling end plate 4 of the heater hydrophobic cooling section and the downstream hydrophobic cooling end plate 5 of the heater hydrophobic cooling section , the adjacent diversion cascades 8 form a diversion cascade channel 9, and the bottom of the drain cooling end plate 4 on the upstream side of the heater hydrophobic cooling section and the drain cooling end plate 5 on the downstream side of the heater hydrophobic cooling section is provided with a drainage hole inlet 11 The outlet 12 of the drainage hole is provided on the lower end surface 6 of the hydrophobic cooling end plate of the heater hydrophobic cooling section, and the outlet 12 of the drainage hole is placed on the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com