Mechanical bimetal composite pipe with thickened pipe end lining layer and preparation method thereof

A bimetallic composite pipe, mechanical technology, applied in the field of pipe manufacturing, can solve the problems affecting the material performance of the pipe end base pipe, the influence of the weld strength of the line pipe, and the complexity of the structure and process, so as to improve the mechanical bonding strength and reduce the boring of the pipe Process, the effect of reducing the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

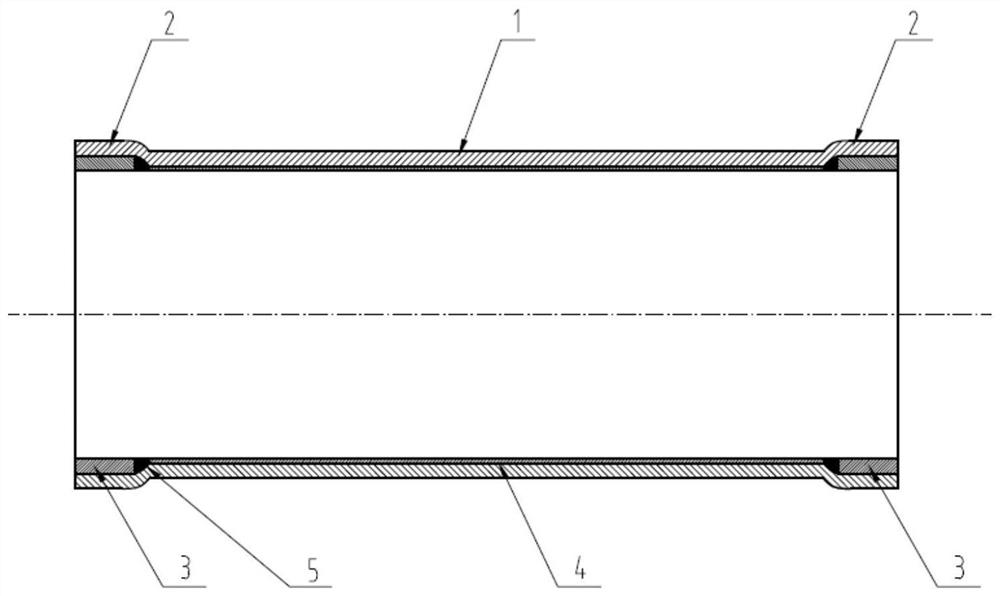

[0039] Such as figure 1 As shown, the mechanical bimetallic composite pipe with a thickened pipe end lining layer in this embodiment includes a base pipe 1 and a liner 4 assembled in the base pipe 1, and both ends of the base pipe 1 exceed the liner 4, And the protruding part of the base pipe 1 is set as an enlarged diameter section 2, and a thickened layer 3 is arranged between the expanded diameter section 2 and the liner pipe 4, and the thickened layer 3 is an inner lining ring, and the thickened layer 3 A weld 5 is formed between the enlarged diameter section 2 and the liner pipe 4, and the inner diameter of the thickened layer 3 is equal to the inner diameter of the liner pipe 4, and the sum of the wall thicknesses of the enlarged diameter section 2 and the thickened layer 3 is greater than that of the liner 4 and the wall thickness of base pipe 1.

[0040] The base pipe 1 in this embodiment is a spiral welded pipe made of Q235B, with an outer diameter of 1321 mm, a wall...

Embodiment 2

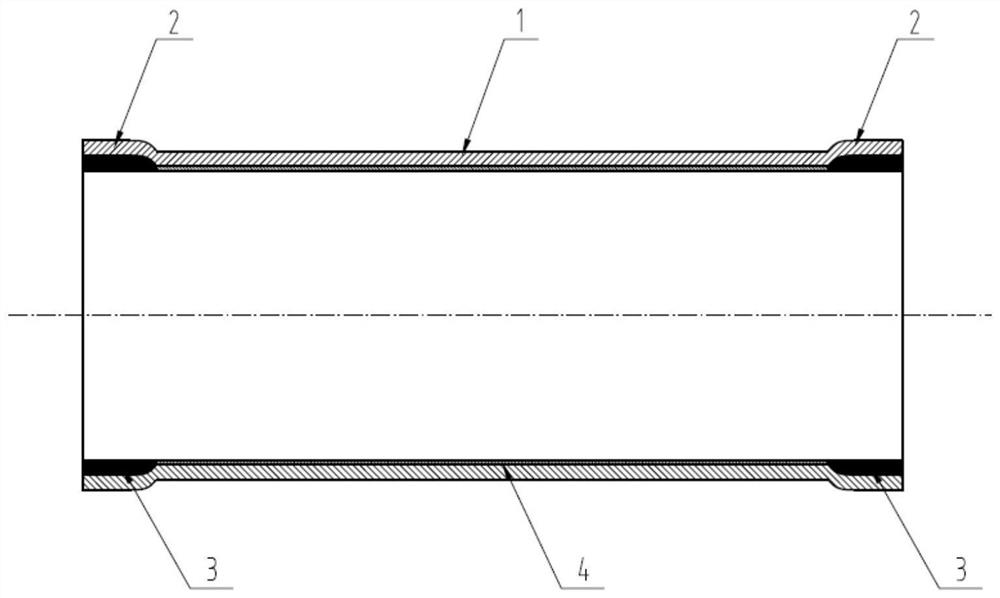

[0052] Such as figure 2 As shown, the mechanical bimetallic composite pipe with a thickened pipe end lining layer in this embodiment includes a base pipe 1 and a liner 4 assembled in the base pipe 1, and both ends of the base pipe 1 exceed the liner 4, And the protruding part of the base pipe 1 is set as a diameter-expanding section 2, and a thickening layer 3 is arranged between the diameter-expanding section 2 and the liner 4, and the thickening layer 3 is a surfacing layer, and the thickening layer 3 The inner diameter of the inner diameter is equal to the inner diameter of the liner 4, and the sum of the wall thicknesses of the expanded diameter section 2 and the thickened layer 3 is greater than the sum of the wall thicknesses of the liner 4 and the base pipe 1.

[0053] The base pipe 1 in this embodiment is a straight seam welded pipe with a material of X52, an outer diameter of 508 mm, a wall thickness of 16 mm, and a length of 11900 mm; the material of the liner pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com