A special medical food thickening component for inhibiting esophageal reflux and preparation method thereof

A technology for esophageal reflux and food, applied in the direction of food ingredients as thickeners, food science, food ingredients, etc., can solve problems such as reflux and suffocation, and achieve the effect of preventing esophagus burns and inhibiting gastroesophageal reflux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Step 1. Weigh 2.0% guar gum, 2.0% locust bean gum, 2.0% xanthan gum, 1.0% carrageenan, 15.0% gelatin, 8.0% gum arabic, 1.0% polydextrose, 1.0% sodium bicarbonate according to the mass percentages. %, glycerol 68.0%, the sum of the mass percentages of the above components is 100%, and the above-mentioned guar gum, locust bean gum, xanthan gum, carrageenan, gum arabic, polydextrose, and sodium bicarbonate are mixed Homogeneous to obtain mixture A.

[0043] Step 2. Mix the gelatin weighed in step 1 with glycerin, heat and stir to 60° C. to obtain a gelatin glycerin solution.

[0044] Step 3. Mix the mixture A formed in step 1 and the gelatin glycerin solution formed in step 2 uniformly to form mixture B.

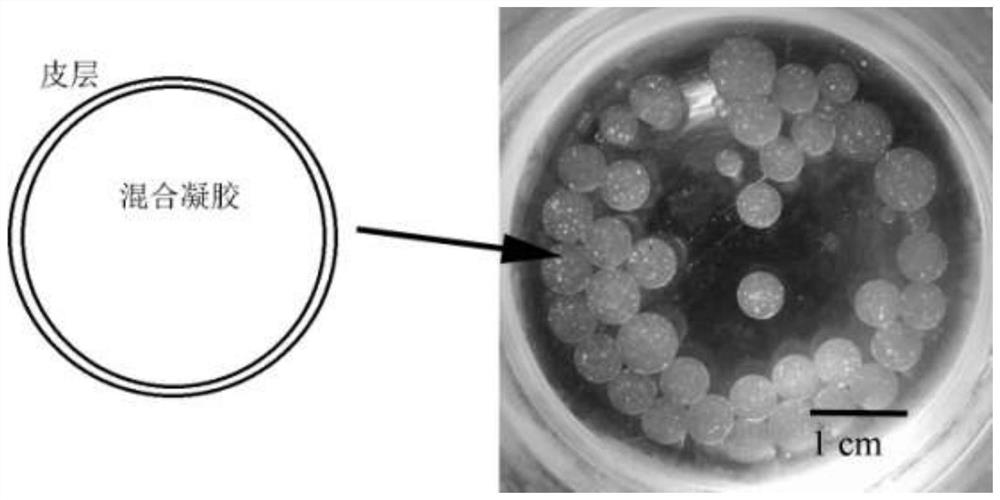

[0045] Step 4. Gradually add the mixture B obtained in step 2 into dimethicone at 5°C under stirring to form a spherical precipitate with a particle size of 0.05 cm.

[0046] Wherein, the mass ratio of mixture B and dimethicone is 1:10.

[0047] Step 5. Filter the sphe...

Embodiment 2

[0049] Step 1. Weigh 6.0% of guar gum, 5.0% of locust bean gum, 6.0% of xanthan gum, 2.0% of carrageenan, 20.0% of gelatin, 11.5% of gum arabic, 0.5% of polydextrose, 2.0% of potassium bicarbonate by mass percentage. %, glycerol 47.0%, the sum of the mass percentages of the above components is 100%. The weighed guar gum, locust bean gum, xanthan gum, carrageenan, gum arabic, polydextrose, and potassium bicarbonate are uniformly mixed to obtain mixture A.

[0050] Step 2. Mix the gelatin weighed in step 1 with glycerin, heat and stir to 80° C. to obtain a gelatin glycerin solution.

[0051] Step 3. Mix the mixture A obtained in step 1 and the gelatin glycerin solution obtained in step 2 uniformly to form mixture B.

[0052] Step 4. Add the mixture B obtained in step 3 into liquid paraffin at 10° C. under stirring to obtain spherical precipitates with a particle size of 0.8 cm.

[0053] Wherein, the mass ratio of mixture B and liquid paraffin is 1:11.5.

[0054] Step 5. Filte...

Embodiment 3

[0056] Step 1. Weigh 3.0% of guar gum, 3.0% of locust bean gum, 3.0% of xanthan gum, 1.4% of carrageenan, 17.0% of gelatin, 12.0% of gum arabic, 0.7% of polydextrose, 1.4% of sodium bicarbonate by mass percentage. %, glycerol 58.5%, the sum of the mass percentages of the above components is 100%. The guar gum, locust bean gum, xanthan gum, carrageenan, gum arabic, polydextrose, and sodium bicarbonate that were weighed above were mixed uniformly to obtain mixture A.

[0057] Step 2. Mix the gelatin weighed in step 1 with glycerin, heat and stir to 68° C. to obtain a gelatin glycerin solution.

[0058] Step 3. Mix the mixture A obtained in step 1 and the gelatin glycerin solution obtained in step 2 uniformly to form mixture B.

[0059] Step 4. Gradually add the mixture B obtained in step 3 into dimethicone at 7°C under stirring to form a spherical precipitate with a particle size of 0.2 cm.

[0060] Wherein, the mass ratio of mixture B and dimethicone was 1:13.

[0061] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com