A kind of soluble/crackable/self-thickening surfactant and preparation method

A surfactant and easy-to-dissolve technology, applied in chemical instruments and methods, dissolution, carboxylate preparation, etc., can solve the problems of increased cost of viscoelastic fluids, increased system complexity, high toxicity and irritation, etc., to achieve Convenient on-site preparation, reduced viscosity, and strong salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

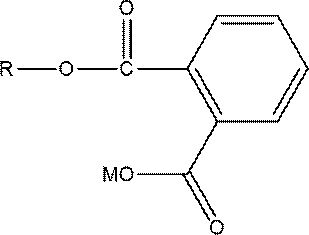

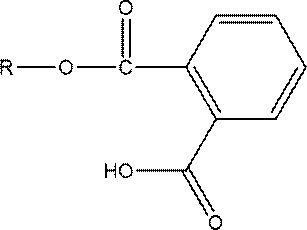

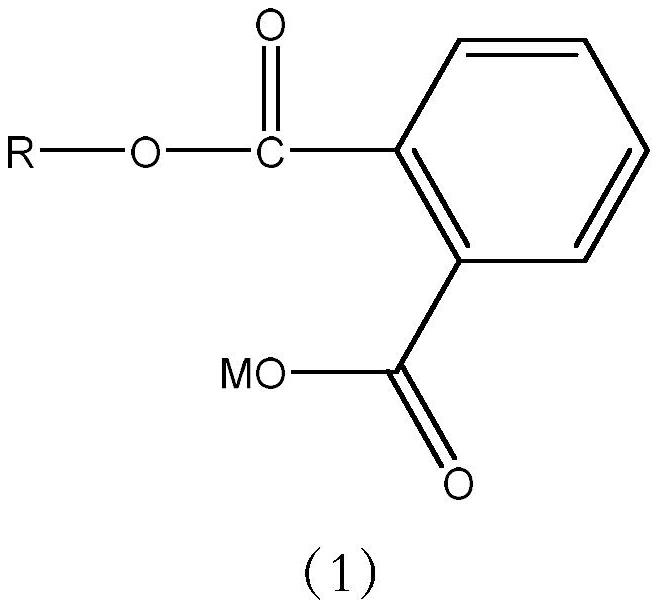

Method used

Image

Examples

Embodiment 1

[0037] Add 10 mmoles of mustard alcohol and 10 mmoles of phthalic anhydride into the flask, heat to 100° C., stir and reflux for 1 hour. The product was transferred to petroleum ether for stirring, washed, suction filtered, and vacuum-dried to obtain a white powder, namely erucyl phthalate monoester, and the yield was 90% as determined by high performance liquid chromatography.

[0038] Weigh 3 mmoles of erucyl phthalate monoester and 3 mmoles of choline hydroxide and dissolve in water, stir at room temperature for 0.5 hour, and spin the solvent to obtain erucyl phthalate monoester choline salt.

Embodiment 2

[0040] Add 10 mmoles of behenyl alcohol and 10 mmoles of phthalic anhydride into the flask, heat to 140° C., stir and reflux for 4 hours. The product was transferred to petroleum ether for stirring, washed, suction filtered, and vacuum-dried to obtain a white powder, ie behenyl phthalate monoester, with a yield of 92% as measured by high performance liquid chromatography.

[0041] Weigh 3 mmoles of behenyl phthalate monoester and 3 mmoles of benzyltrimethylammonium hydroxide and dissolve them in methanol, stir at room temperature for 1 hour, spin the solvent to obtain behenyl phthalate monoester benzyl Trimethyl quaternary ammonium salt.

Embodiment 3

[0043] Add 10 mmol arachidene alcohol and 10 mmol phthalic anhydride into the flask, heat to 120° C., stir and reflux for 2 hours. The product was transferred to petroleum ether for stirring, washed, suction filtered, and vacuum-dried to obtain a white powder, that is, arachidene alcohol phthalate monoester, and the yield was 96% as determined by high performance liquid chromatography.

[0044] Weigh 3 mmoles of arachidyl phthalate monoester and 3 mmoles of tetramethylammonium hydroxide and dissolve them in ethanol, stir at room temperature for 1.5 hours, and spin the solvent to obtain arachidyl phthalate monoester tetramethyl quaternary ammonium salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com