High-precision six-degree-of-freedom measurement method and device based on laser range finder

A technology for a laser rangefinder and a measuring device, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of complex structure and low measurement accuracy, and achieve the effects of simple and compact structure, high precision and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

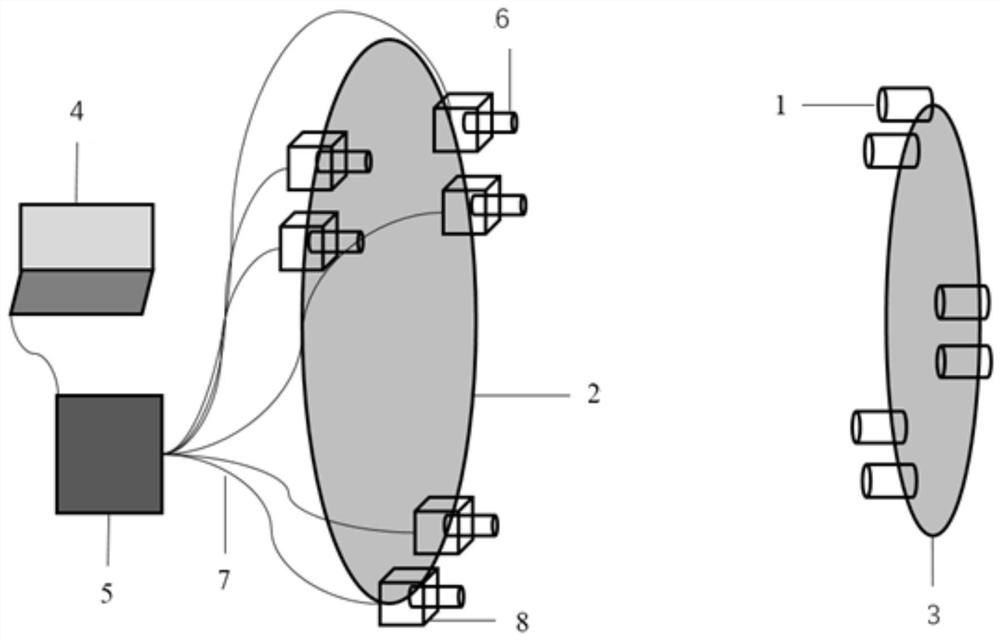

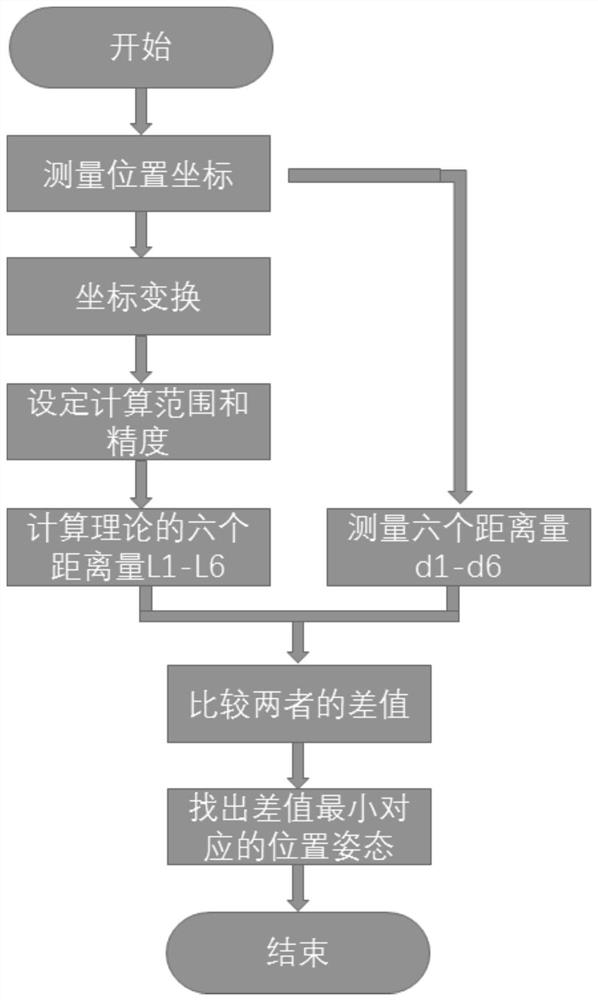

[0017] combine first figure 1 A high-precision six-degree-of-freedom measuring device based on a laser rangefinder is introduced. The main components of the measuring device include a high-precision laser range finder, six external reflection cube mirrors 1, a static coordinate plate 2, a moving coordinate plate 3, and a data processing system 4; among them, the high-precision laser interferometric range finder in the measuring device includes a laser Interferometer host 5, control software, six laser output ends 6 and six optical fibers 7; the six laser output ends 6 are respectively fixed on the edge of the static coordinate plate through six adjustable mirror frames 8, and connected to the laser through six optical fibers 7 The interferometer host 5 is connected; the six external reflection cube mirrors 1 are fixed on the edge of the moving coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com