Button crack detection device capable of being operated in batches

A batch operation and detection device technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as skin scratches, bacterial infections, and large quantities of buttons produced, and achieve the effect of avoiding injuries and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

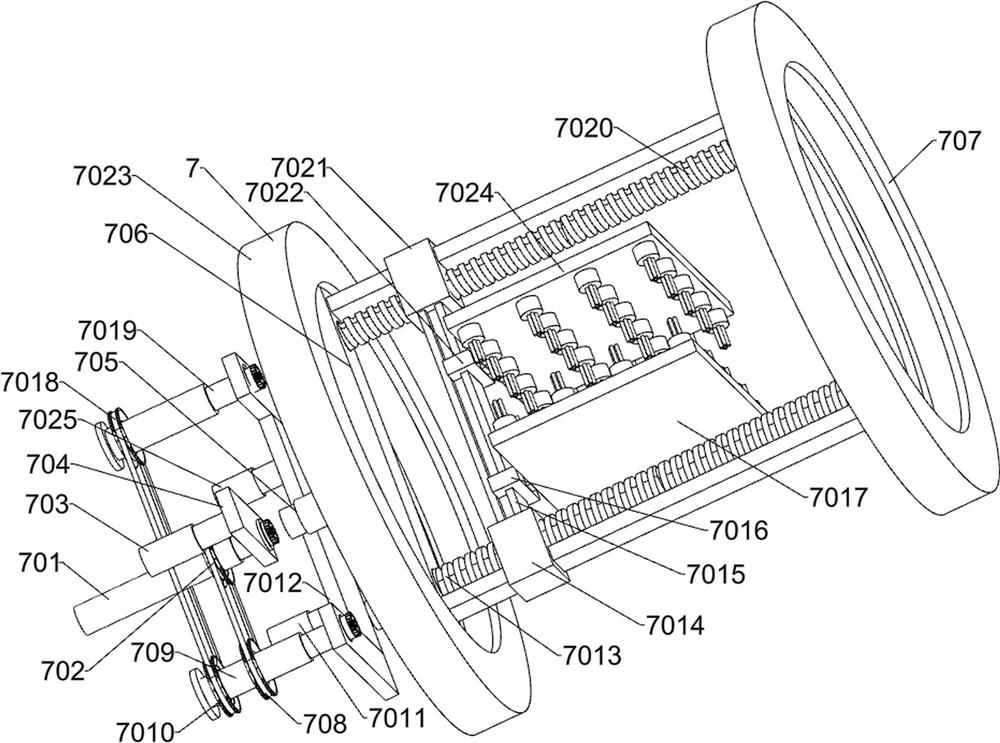

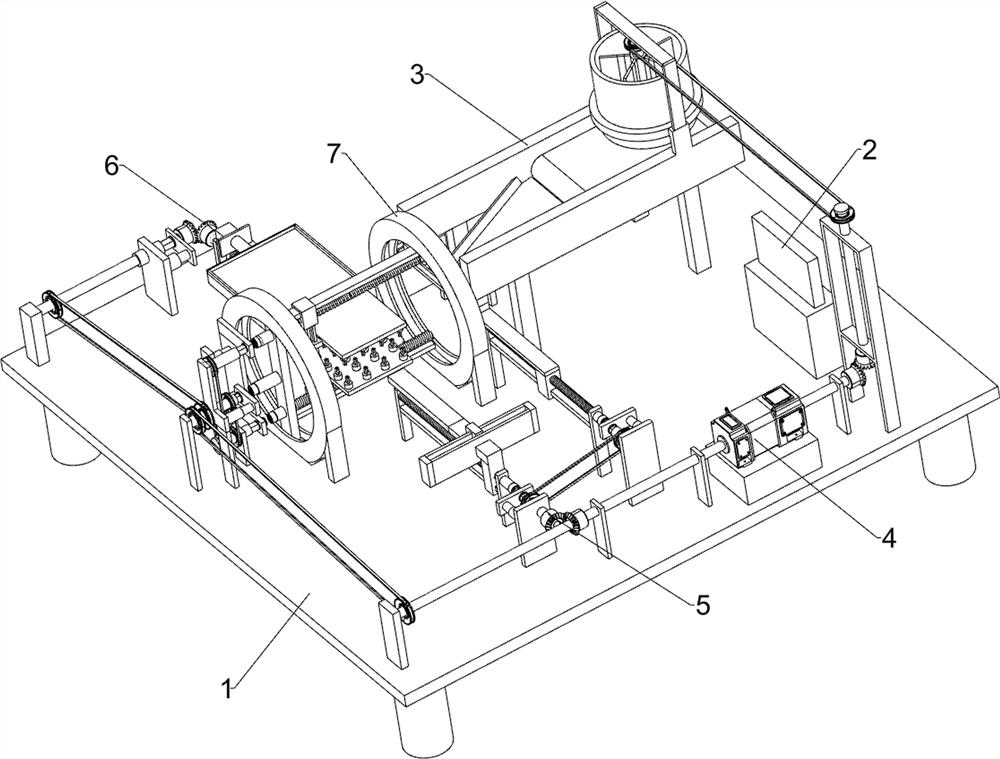

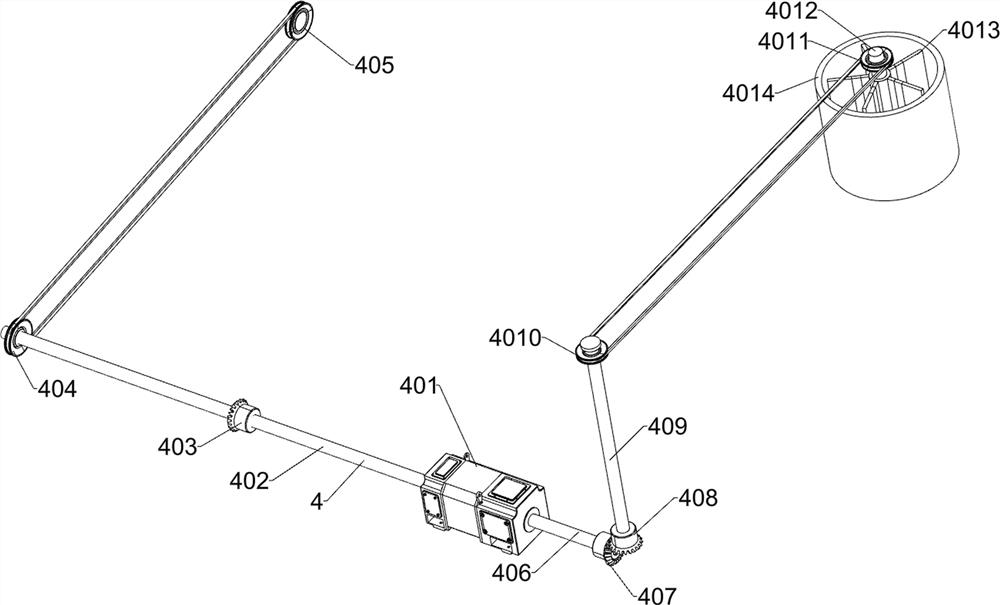

[0027] A commercially operable button crack detection device, such as Figure 1-6 As shown, including a table 1, a control screen 2, a transfer mechanism 3, a sheet mechanism 4, a detecting mechanism 5, a collection mechanism 6, and a finishing mechanism 7; a table 1 is connected to the control screen 2; a workbench 1 and a transfer mechanism 3 phase connection; the table 1 is connected to the sheet of the sheet; the table 1 is connected to the detection mechanism 5; the table 1 is connected to the collecting mechanism 6; the table 1 is connected to the finishing mechanism 7; transport mechanism 3 and down The material 4 is connected; the conveying mechanism 3 is provided with a detection mechanism 5; the lower material 4 is connected to the detecting mechanism 5; the lower material 4 is connected to the finishing mechanism 7; the collecting mechanism 6 is connected to the finishing mechanism 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com