Bar and pipe cutting treatment device for building material machining

A processing device and rod material technology, which is applied in the field of bar and pipe material cutting and processing devices for building materials processing, can solve the problems of unguaranteed size, danger, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

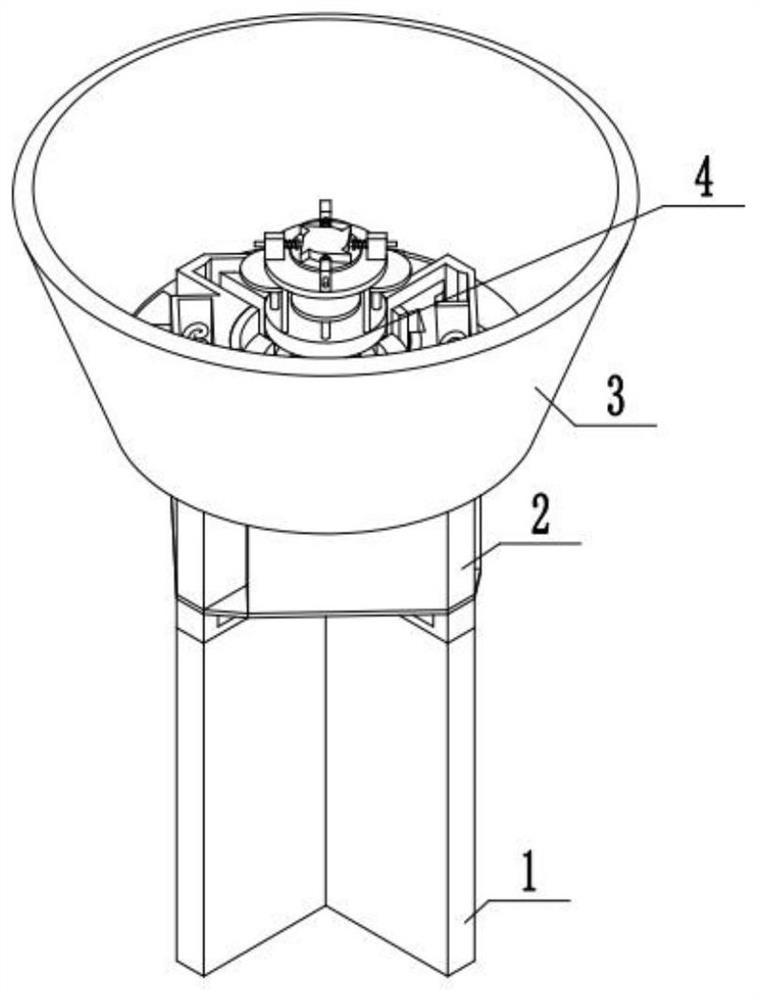

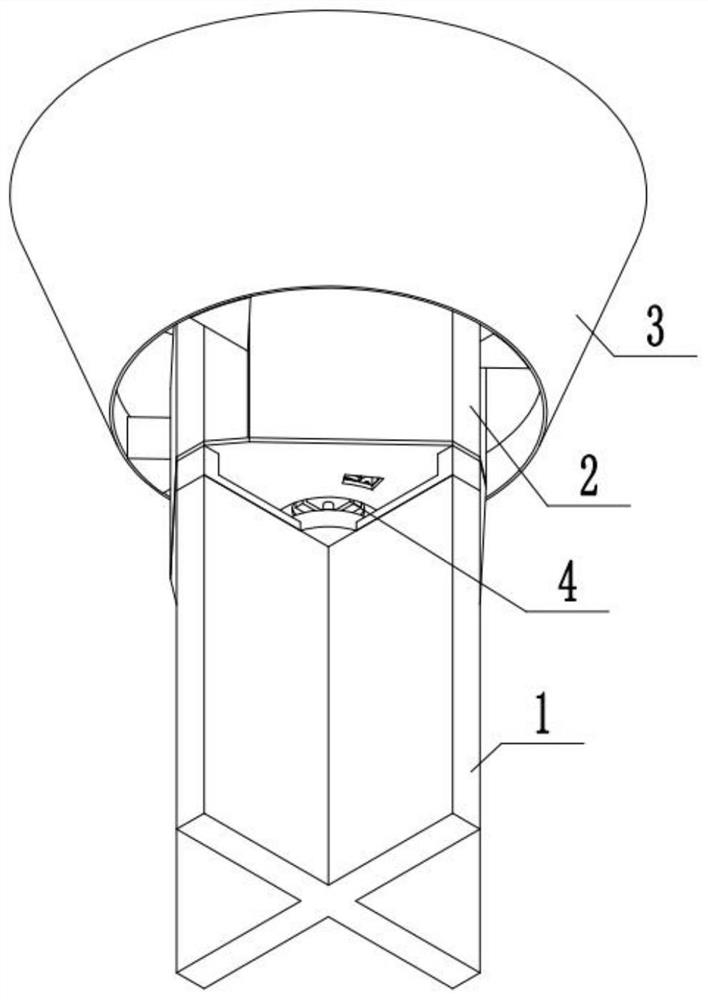

[0036] Combine below figure 1 , 2Description of this embodiment, a bar and pipe cutting processing device for building materials processing, including a fixed cross base 1, a storage and feeding device 2, a leftover material collection device 3 and a cutting processing device 4, and the top of the cross base 1 is fixedly installed with The cutting processing device 4 is provided with a storage and feeding device 2 , and the scrap collecting device 3 is slidably installed on the cutting processing device 4 .

specific Embodiment approach 2

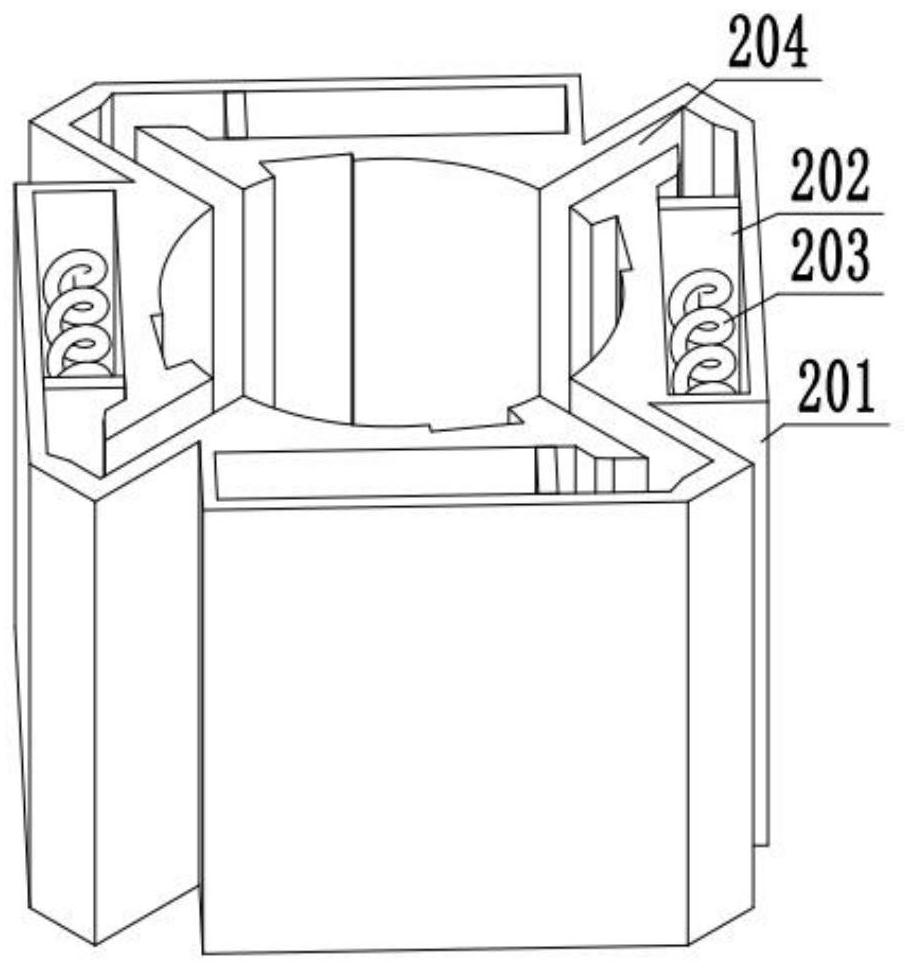

[0038] Combine below image 3 Describe this embodiment, this embodiment will further explain the first embodiment, the storage and feeding device 2 includes a storage sleeve 201, a feed plate 202, a feed spring 203, a feed sleeve 204, the storage sleeve 201 and The feed sleeve body 204 is connected, and the feed sleeve body 204 at the communication position is provided with a slope, the feed plate 202 is slidably installed on the storage sleeve body 201, and the two ends of the feed spring 203 are respectively fixedly installed on the storage sleeve body 201 and the feeding sleeve body 201. On the plate 202, the storage sleeve body 201 is provided with a drop groove, the bar or plate is placed in the storage sleeve body 201, the feed spring 203 pushes the feed plate 202 through its own elasticity, and the feed plate 202 pushes the bar or pipe , so that the bar or pipe enters the feeding sleeve 204 through the inclined surface provided on the feeding sleeve 204, so as to realiz...

specific Embodiment approach 3

[0040] Combine below Figure 4 , 5 Describe this embodiment, this embodiment will further explain Embodiment 1, the leftover material collection device 3 includes a collection sleeve body 301, a sleeve body connection block 302, and a sleeve body connection block 302 is fixedly installed on the collection sleeve body 301, the sleeve body The connecting block 302 is provided with a hydraulic lift, and the cover body connecting block 302 is slidably installed on the storage cover body 201, and the hydraulic lift configured by the cover body connecting block 302 is started, so that the cover body connecting block 302 drives the collection cover body 301 to move upwards to realize Block and collect the scraps that fly out, prevent the scraps from hurting people, and collect the scraps at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com