Needle tubing type silicone grease processing device capable of separating labels

A technology for separating labels and processing devices, applied in the directions of labels, labeling, rigid containers with short marks, etc., can solve the problems of label wrinkles, messy needle-type silicone grease, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

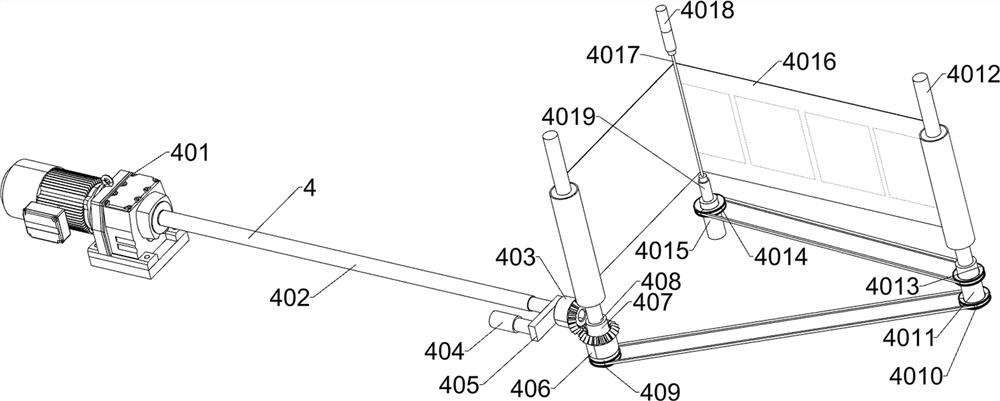

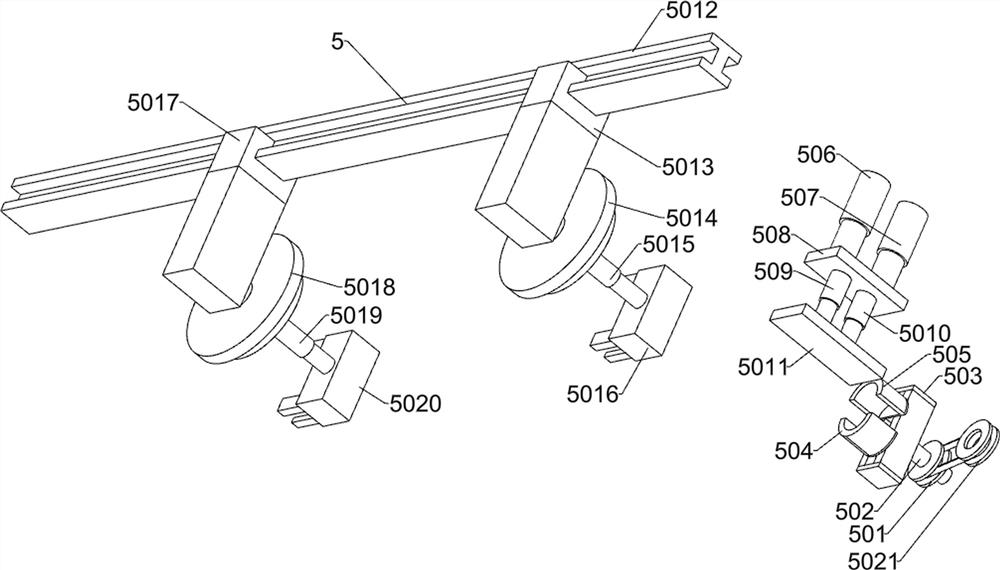

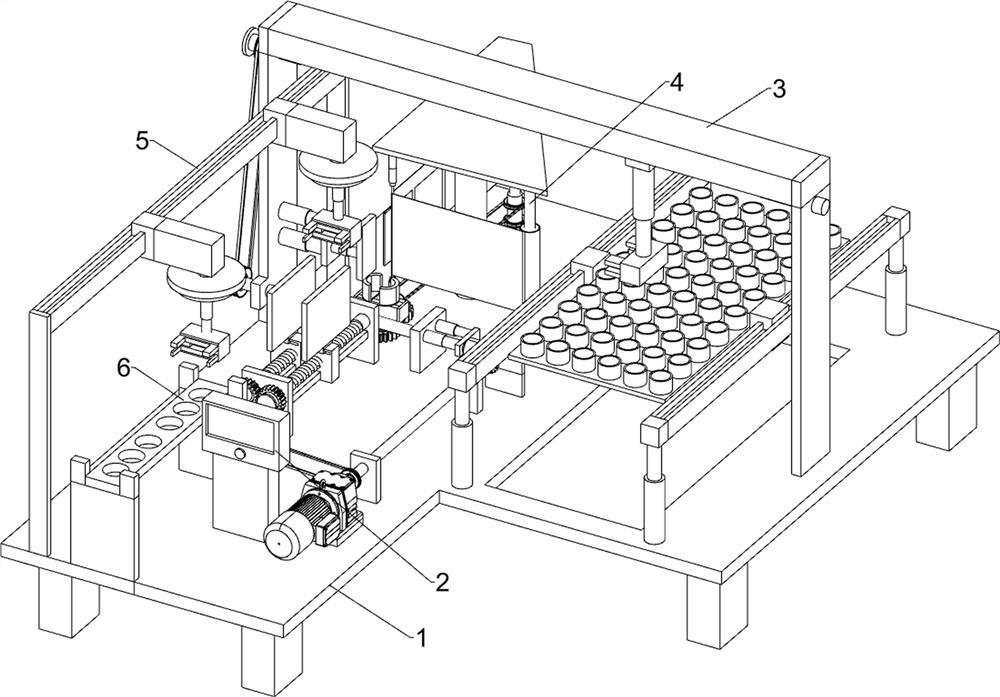

[0026] A syringe-type silicone grease processing device with detachable labels, such as Figure 1-6 As shown, it includes workbench 1, control panel 2, feeding mechanism 3, separation mechanism 4, transport mechanism 5 and laminating mechanism 6; workbench 1 is connected with control panel 2; workbench 1 is connected with feeding mechanism 3 Connection; workbench 1 is connected with separation mechanism 4; workbench 1 is connected with transportation mechanism 5; workbench 1 is connected with laminating mechanism 6; feeding mechanism 3 is connected with separation mechanism 4; separation mechanism 4 is connected with transportation mechanism 5 are connected; the separation mechanism 4 is connected with the bonding mechanism 6.

[0027] Working process: when the device is in use, first manually place the needle-type silicone grease needle tube downward on the feeding mechanism 3, and install the material paper on the separation mechanism 4, and manually operate the control pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com