Civil and constructional engineering site reinforcing steel bar detector

A technology for civil construction and testing instruments, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of inconvenient placement and use of instruments, and achieves the effect of being simple to use and reducing the risk of accidental breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0024] The embodiments of the present invention will be described below according to the overall structure of the present invention.

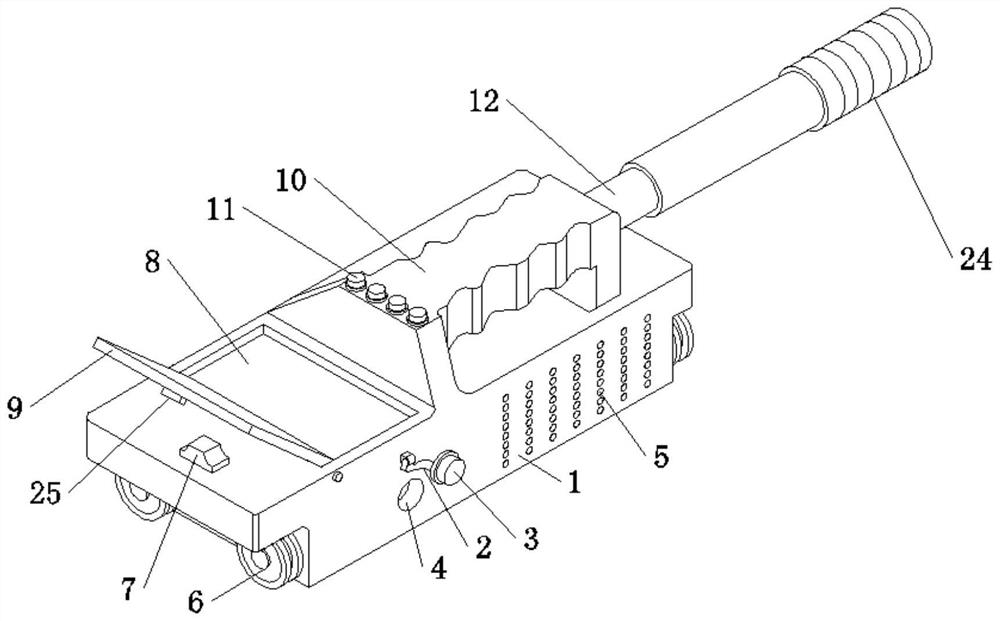

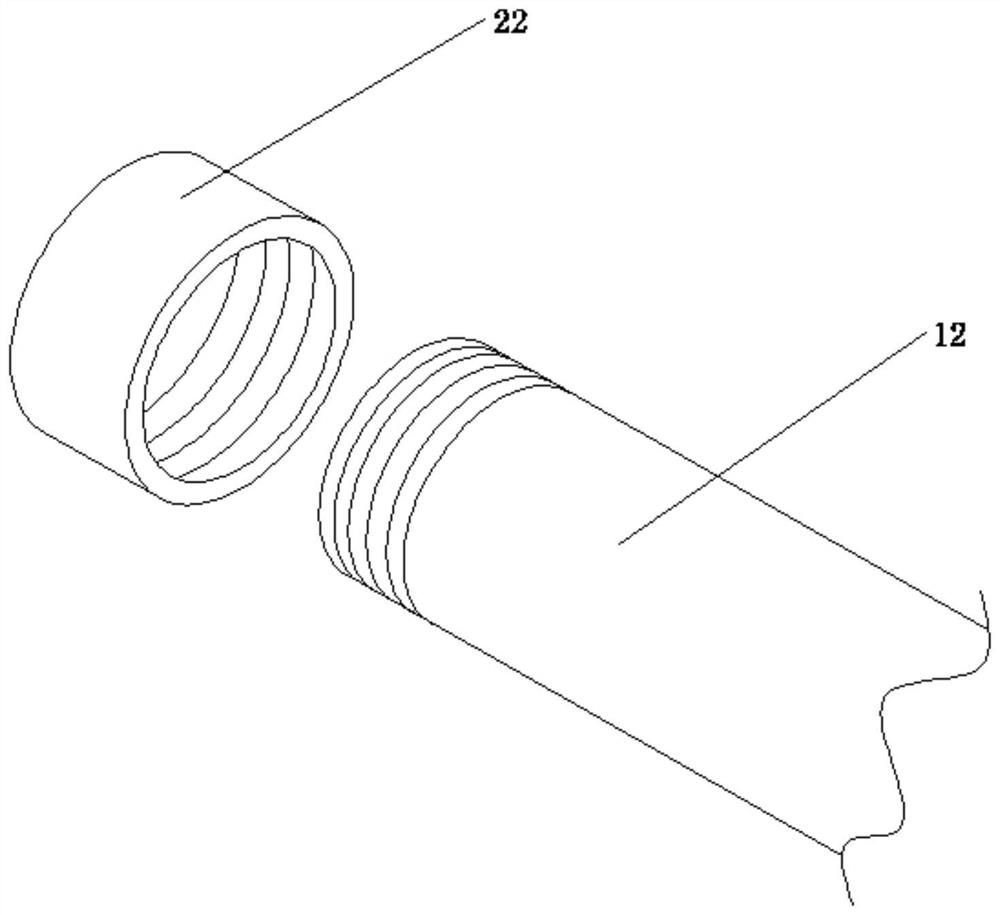

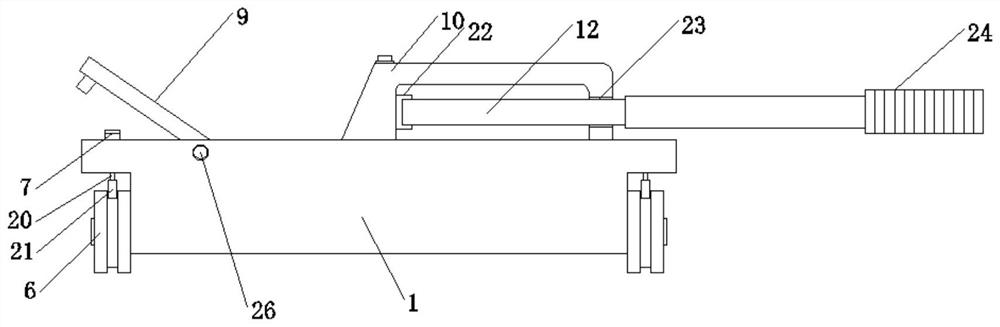

[0025] see Figure 1-5 , On-site steel bar detector for civil and construction engineering, including instrument main body 1, connecting belt 2, sealing plug 3, charging port 4, cooling hole 5, roller 6, pressing block 7, protection groove 8, display screen 9, handle 10, control key 11. Telescopic rod 12, pressing column 13, connecting plate 14, slider 15, chute 16, first limit block 17, second limit block 18, spring 19, fixed rod 20, brake piece 21, threaded cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com