Product positioning test system and test method

A product testing and product technology, applied in the direction of software testing/debugging, error detection/correction, instruments, etc., can solve problems such as the influence of the actual situation of the test, the insufficient execution of test cases, and the impact on test efficiency, so as to reduce labor. The effect of operation intensity, full coverage, and stable data interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the positioning product testing system and testing method of the present invention will be described in detail below in conjunction with the accompanying drawings.

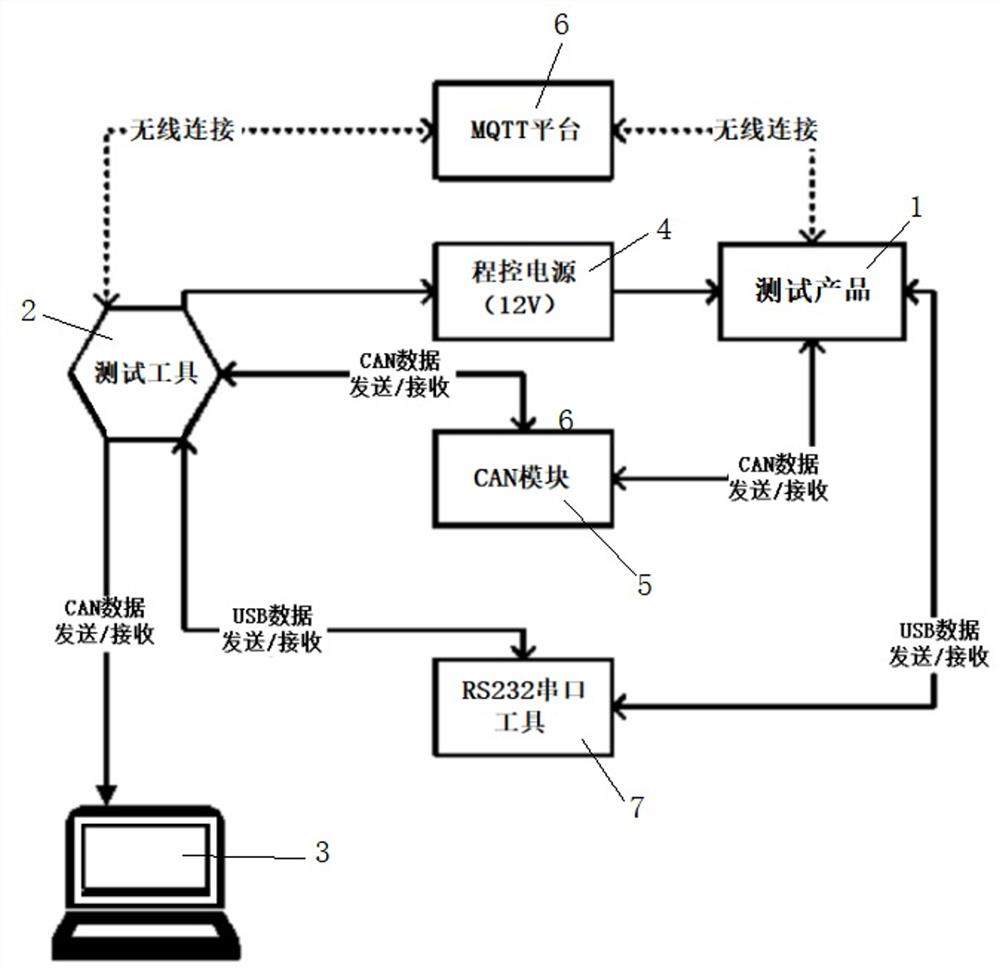

[0024] See attached figure 1 , The positioning product test system includes a test product 1, a test tool 2, a terminal 3 and a programmable power supply 4, the test product 1 and the test tool 2 are connected through a transmission protocol, and the test tool 2 sends instructions and receives feedback to the test product 1 through a transmission protocol. The test tool 2 is connected to the terminal 3 for communication, and the transmission protocols include CAN port protocol, MQTT data transmission protocol and RS-232 data transmission protocol. The program-controlled power supply 4 provides 12V direct current, while the test tool 2 controls the program-controlled power supply 4 to supply power to the test product.

[0025] CAN port protocol realizes data transmission betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com