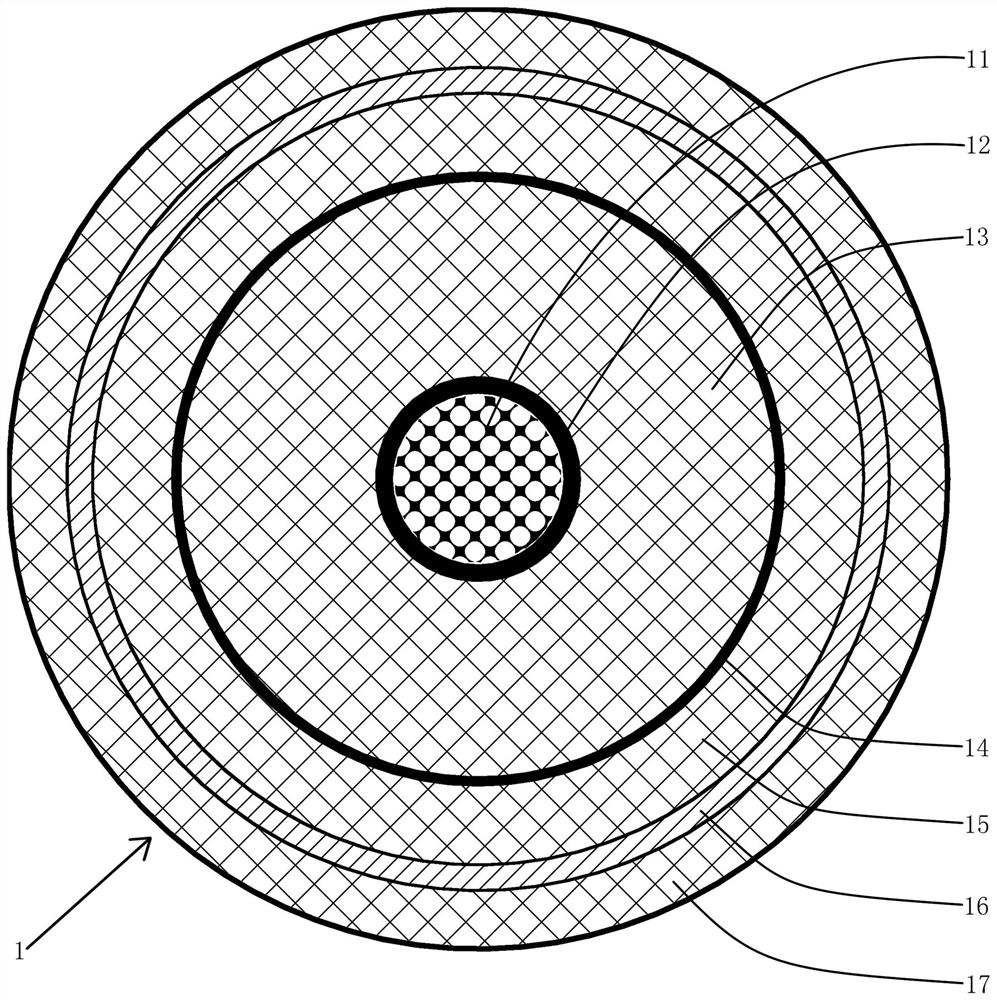

Tool for stripping outer sheath and insulating layer of high-voltage cross-linked polyethylene insulated power cable

A cross-linked polyethylene and power cable technology, applied in the direction of circuits, electrical components, circuit/collector components, etc., to reduce workload, improve work efficiency, and avoid personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

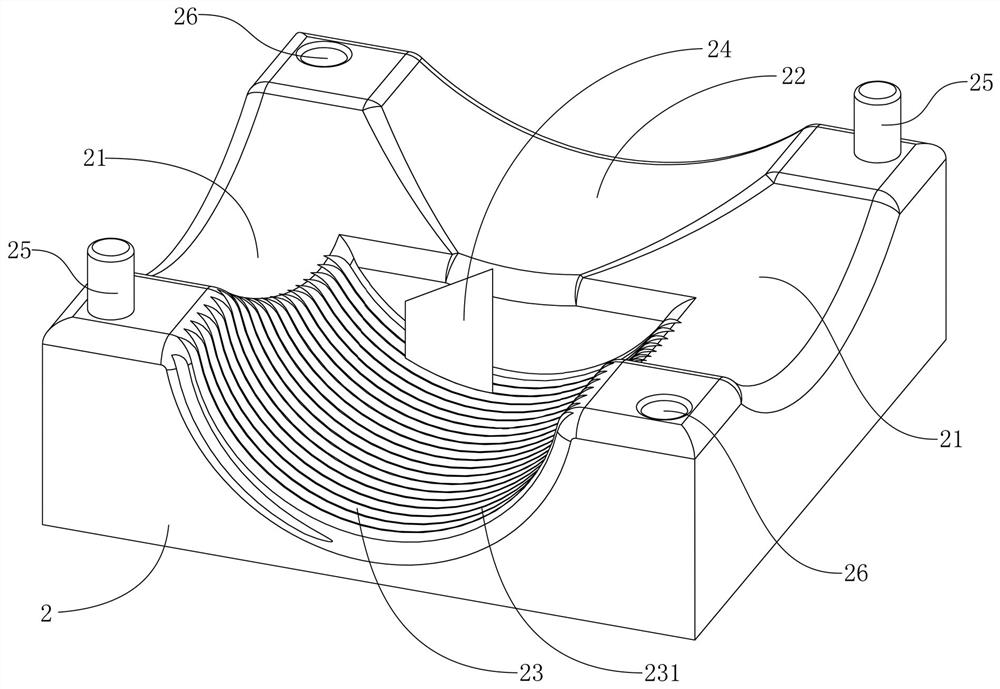

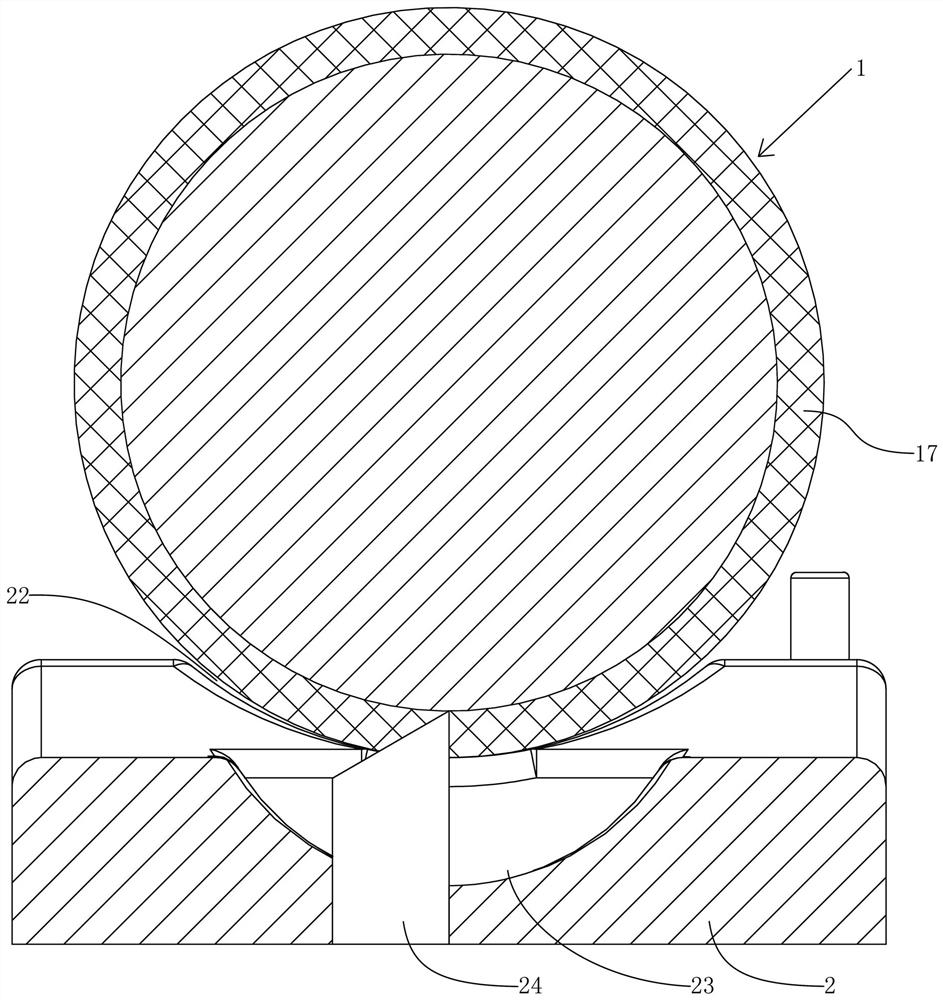

[0049] refer to Figure 2-Figure 5 , the high-voltage cross-linked polyethylene insulated power cable outer sheath and the insulation layer stripping tool provided in this embodiment include a cutting mechanism 2, the cutting mechanism 2 is a cube structure, and the upper parts of the left and right sides are provided with holes that penetrate the cutting mechanism 2 in the left and right directions. Left and right arc-shaped grooves 21, the upper part of the rear side is provided with a rear arc-shaped groove 22 that runs through the cutting mechanism 2 in the front and rear direction; the specifications of the left and right arc-shaped grooves 21 and the rear arc-shaped groove 22 are consistent, and the central axes are located Above the mechanism 2 and at the same height, the central axes are perpendicular to each other and parallel to the bottom surface of the cutting mechanism 2; diameter) match.

[0050] The top of cutting mechanism 2 front sides is provided with front ...

Embodiment 2

[0056] refer to Figure 6-Figure 8 Compared with Embodiment 1, the high-voltage XLPE insulated power cable outer sheath and insulation layer stripping tool provided in this embodiment have been improved as follows: the left and right arc grooves 21 are not provided, and the cutting direction can be adjusted by the blade 24. .

[0057] Such as Figure 7 As shown, the root of the blade of the blade 24 is provided with a cylindrical turntable 241, the central axis of the turntable 241 is collinear with the blade of the blade 24, and the bottom of the turntable 241 is provided with a coaxial threaded rod, and the threaded rod is provided with a The matching knurled nut 242 is used to fix the blade 24 on the cutting mechanism 2 .

[0058] Corresponding, such as Figure 8 As shown, the upper and lower axes of the cutting mechanism 2 are hollowed out with a mounting hole 232 that is in clearance with the threaded rod at the bottom of the turntable 241, and the upper and lower axes...

Embodiment 3

[0062] refer to Figure 9 , the high-voltage cross-linked polyethylene insulated power cable outer sheath and the insulation layer stripping tool provided by this embodiment have been improved as follows compared with embodiment 2: no positioning column 25 and positioning hole 26 are provided, and the cutting mechanism 2 top Fastening holes 27 are hollowed out near the two corners of the front arc groove 23;

[0063] When the insulation layer 13 needs to be cut, the two cutting mechanisms 2 can be arranged oppositely, and the fastening rod 3 can pass through the two relative fastening holes 27. The fastening rod 3 is a threaded rod, so the nut can be used to The two front arc-shaped grooves 23 are pressed against the insulating layer 13 to prevent the cutting mechanism 2 from slipping when rotating.

[0064] In this embodiment, one end of the fastening rod 3 connected to the cutting mechanism 2 is provided with a multi-angle limiter 32. In order to prevent the fastening rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com