Electronic cigarette atomizer

An electronic cigarette atomizer and smoke technology, which is applied in the field of electronic cigarettes, can solve the problems of unsatisfactory users and insufficient concentration of taste, and achieve the best atomization effect, high reduction degree of smoke oil, and full smoke volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

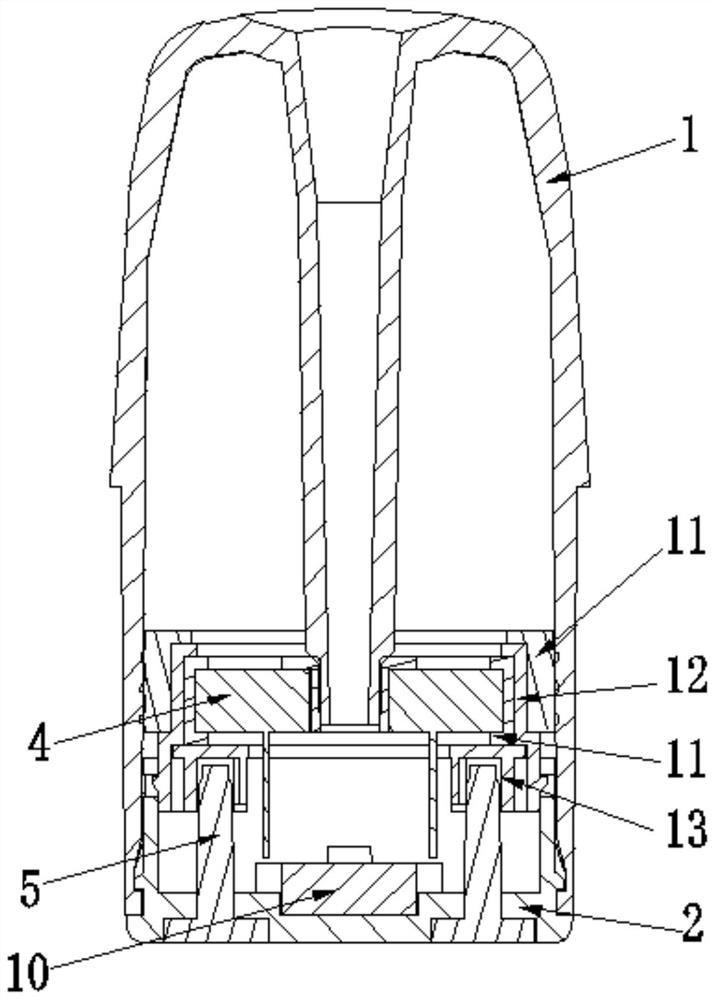

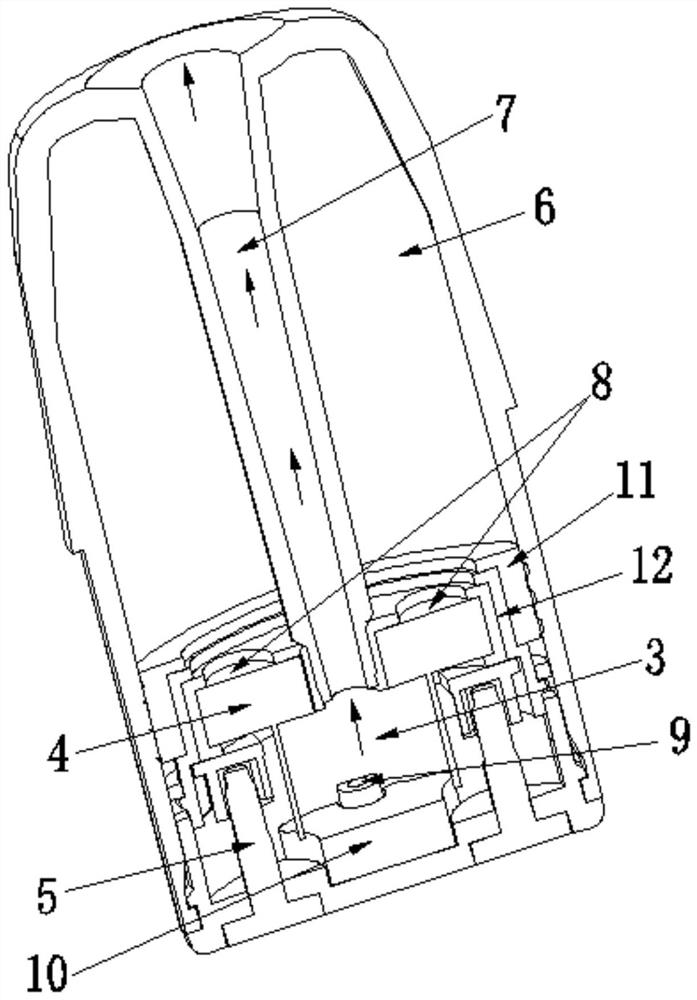

[0016] Such as figure 1 , 2 As shown, the present invention discloses an electronic vaporizer, which includes an oil tank 1, an oil tank base 2, an atomization tank 3, a ceramic heating wire 4, and an electrode 5. The oil tank base 2 is installed on the oil tank 1 At the bottom, the inside of the oil tank 1 is provided with an oil storage tank 6 and an air outlet pipe 7, the atomization tank 3 is located inside the oil tank 1, and the ceramic heating wire 4 and the The electrode 5, the electrode 5 is used to supply power to the ceramic heating wire 4, the atomization chamber 3 is provided with an oil guide hole 8, and the position of the oil guide hole 8 corresponds to the position of the oil storage tank 6, so The e-liquid in the oil storage chamber 6 flows into the atomization chamber 3 through the oil guide hole 8, and the ceramic heating wire 4 is used to atomize the e-liquid in the atomization chamber 3 to form smoke. The smoke is discharged through the outlet pipe 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com