Waste gas treatment device for 3D printing

An exhaust gas treatment device and 3D printing technology, applied in the field of 3D printing, can solve problems such as air purification, environmental pollution, and environmental pollution, and achieve the effects of meeting practical needs, reducing environmental pollution, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

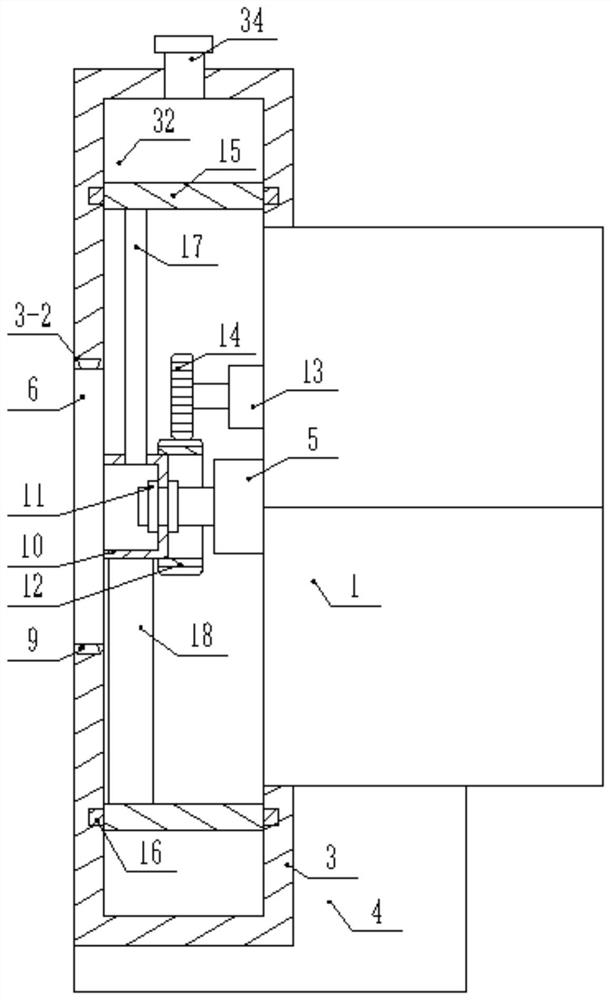

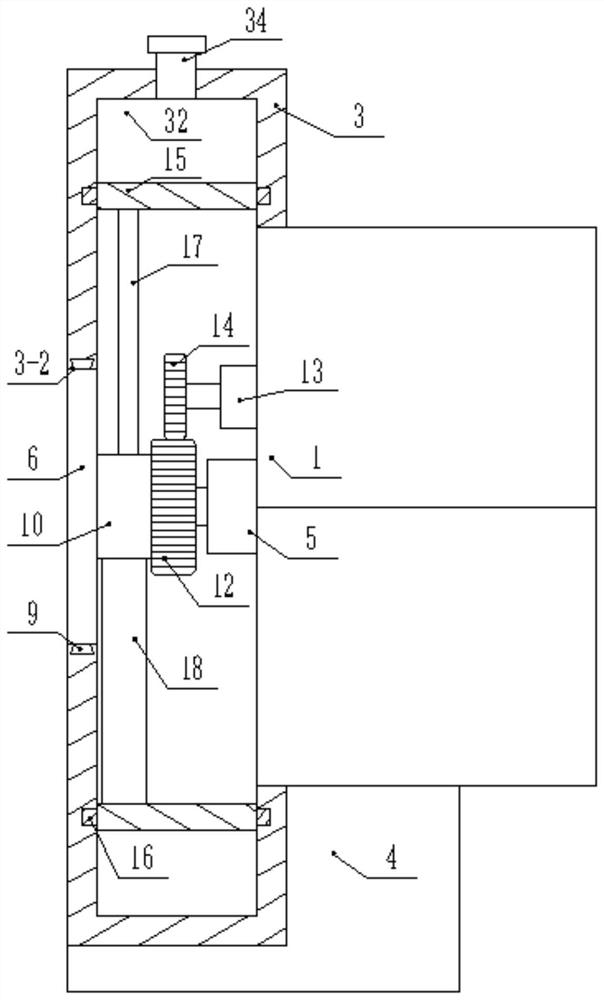

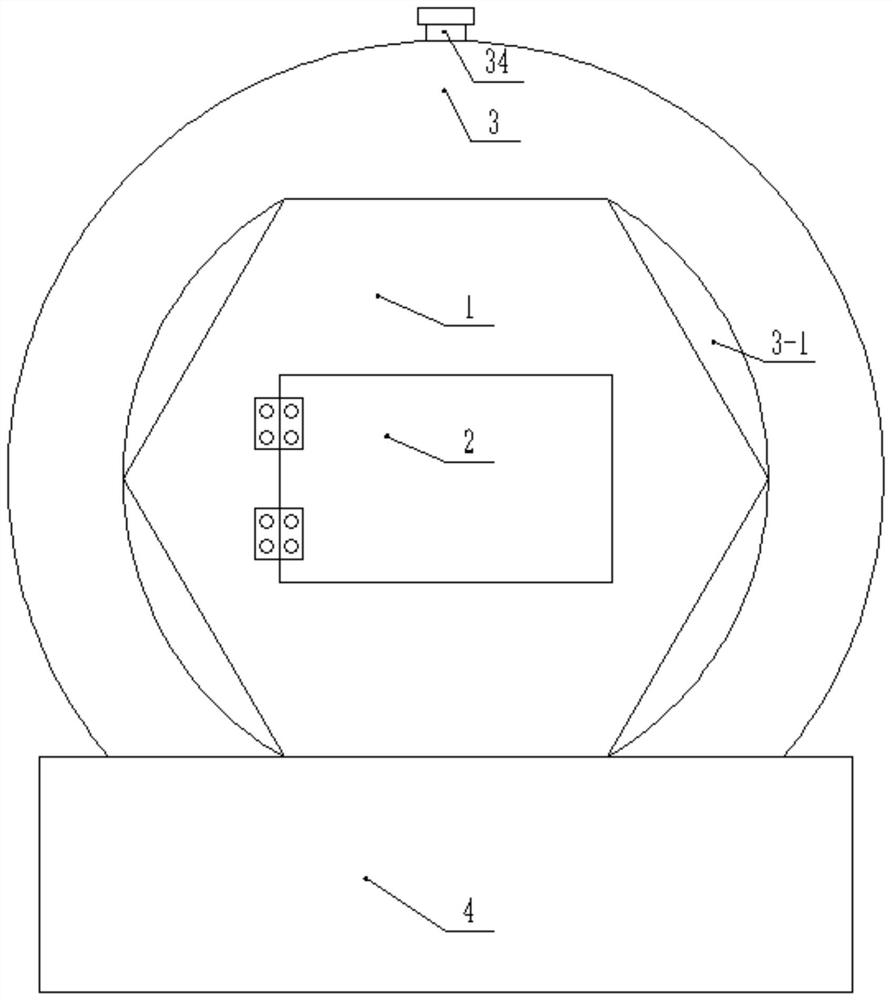

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0018] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6As shown, a waste gas treatment device for 3D printing includes a 3D printer body 1, the 3D printer body 1 is electrically connected to an external controller, the side wall of the 3D printer body 1 is hinged with an organic door 2 through a hinge, the One side of the 3D printer body 1 is provided with a first barrel body 3, the section of the first barrel body 3 is circular, the bottom surface of the first barrel body 3 is fixedly connected with a base 4, and the top surface of the base 4 is connected to the 3D printer body 1. The bottom surface is fixedly connected. The side wall of the first barrel body 3 has a first through hole 3-1. One end of the 3D printer body 1 is set in the first through hole 3-1. The 3D printer body 1 and the first through hole 3-1 A b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com