Automatic aluminum alloy fluorocarbon spraying system and fluorocarbon spraying method

A technology of aluminum alloy and fluorocarbon, applied in the field of aluminum alloy, can solve the problems of circumferential spraying, inability to fix pipe fittings of different diameters, poor spraying effect, etc., and achieve the effect of avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

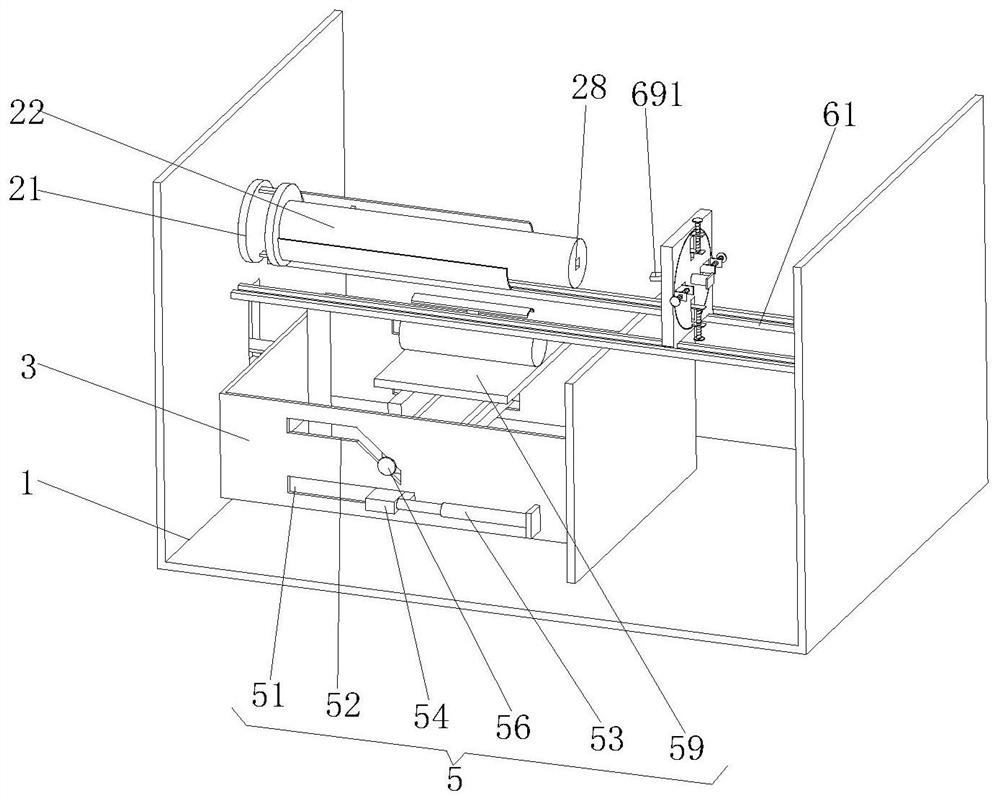

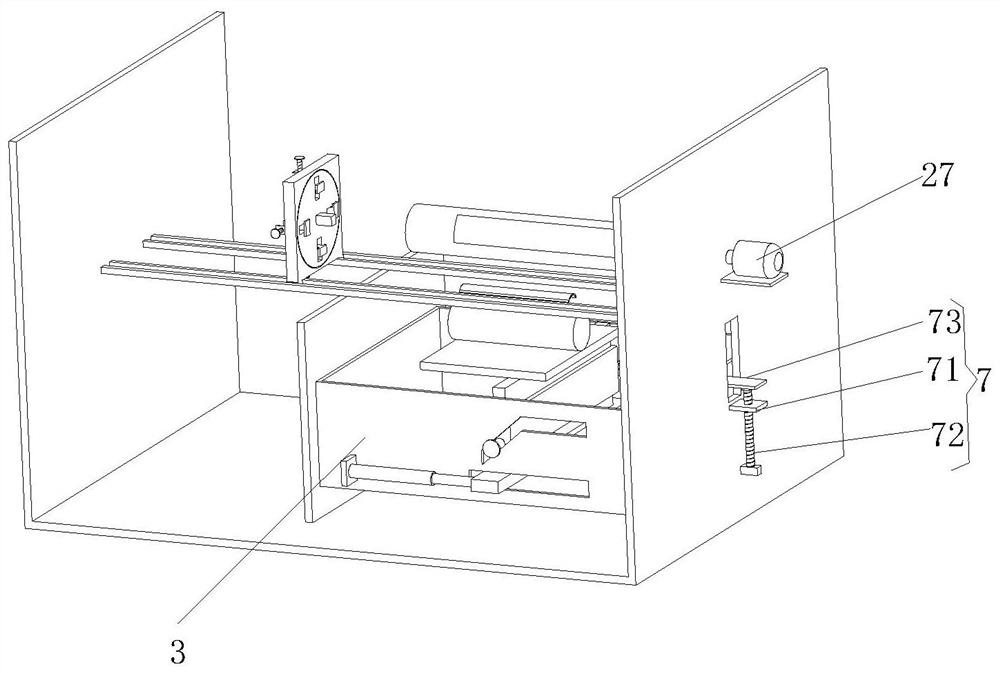

[0038] Such as Figure 1 to Figure 9 As shown, an aluminum alloy automatic fluorocarbon spraying system includes a cylindrical frame 1, a support device 2, a work box 3, a spraying device 4 and a moving device 5, and the left side of the cylindrical frame 1 is provided with a support device 2 , the supporting device 2 is provided with an operation box 3 slidingly connected with the side wall of the inner cavity of the frame 1, the operation box 3 is provided with a spraying device 4, and the operation box 3 inner cavity is provided with a mobile device 5; wherein:

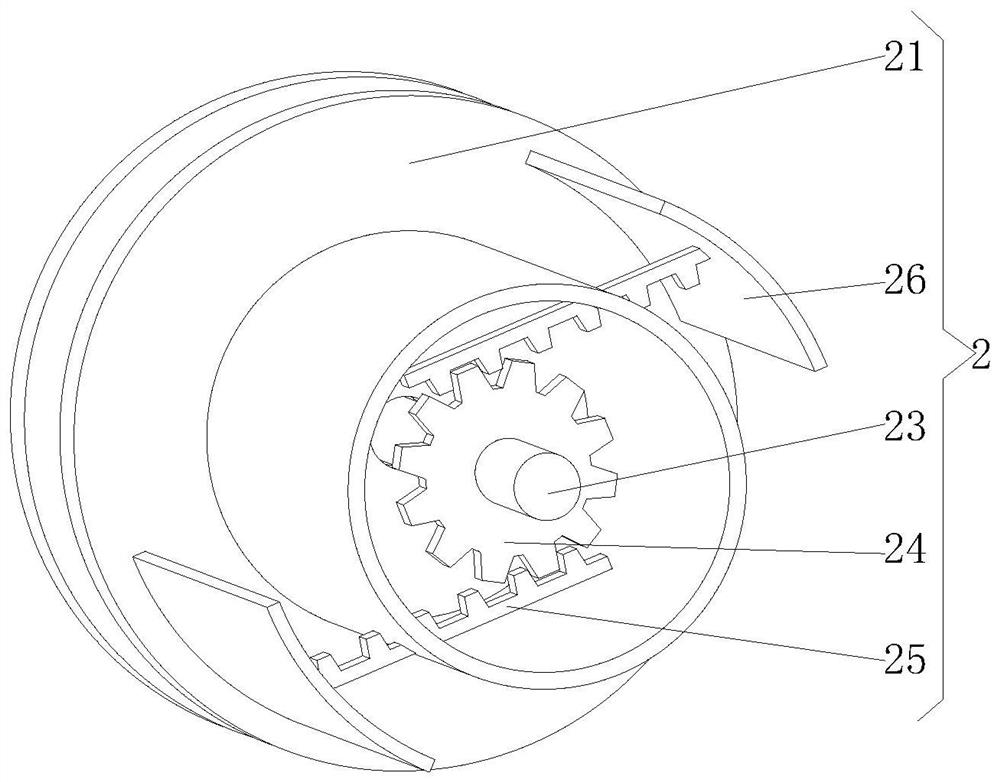

[0039] The supporting device 2 includes a turret 21, a supporting cylinder 22, a driving rod 23, a gear 24, a rack plate 25, a supporting plate 26, a driving motor 27, an alignment groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com