Fire extinguisher bottom plate mounting and correcting integrated device

A fire extinguisher and base plate technology, which is applied in the field of fire extinguisher base plate installation and correction integrated device, can solve the problems such as the inability to detect the level state of the base plate and the inability to correct the base plate, and achieve the effect of simple operation and improved installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

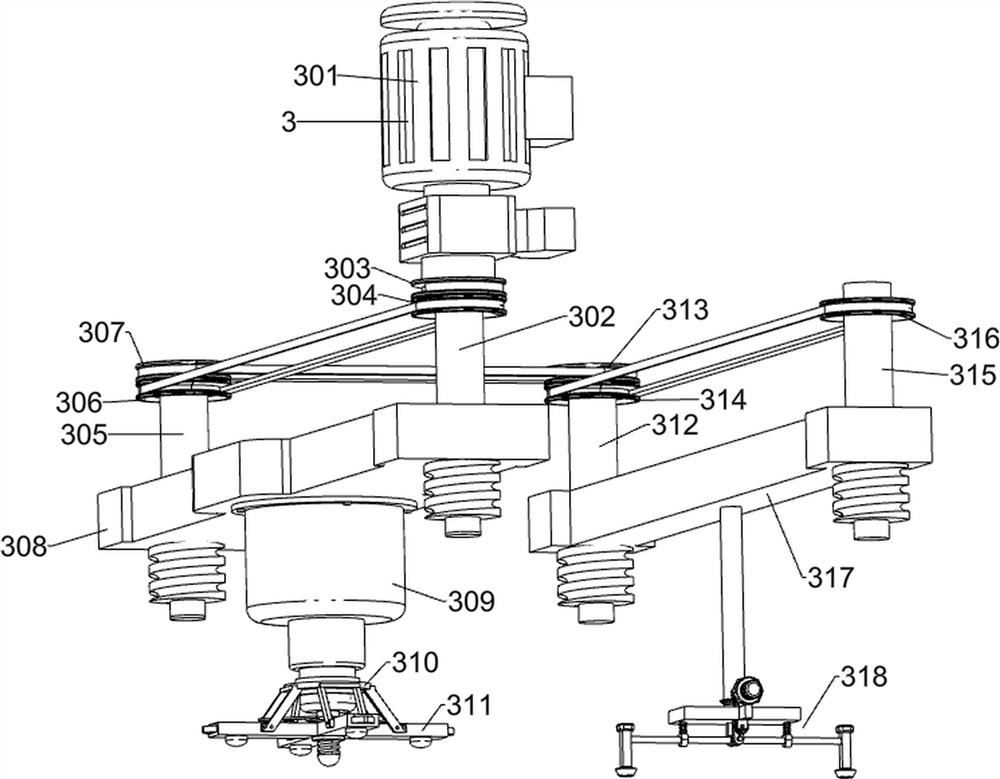

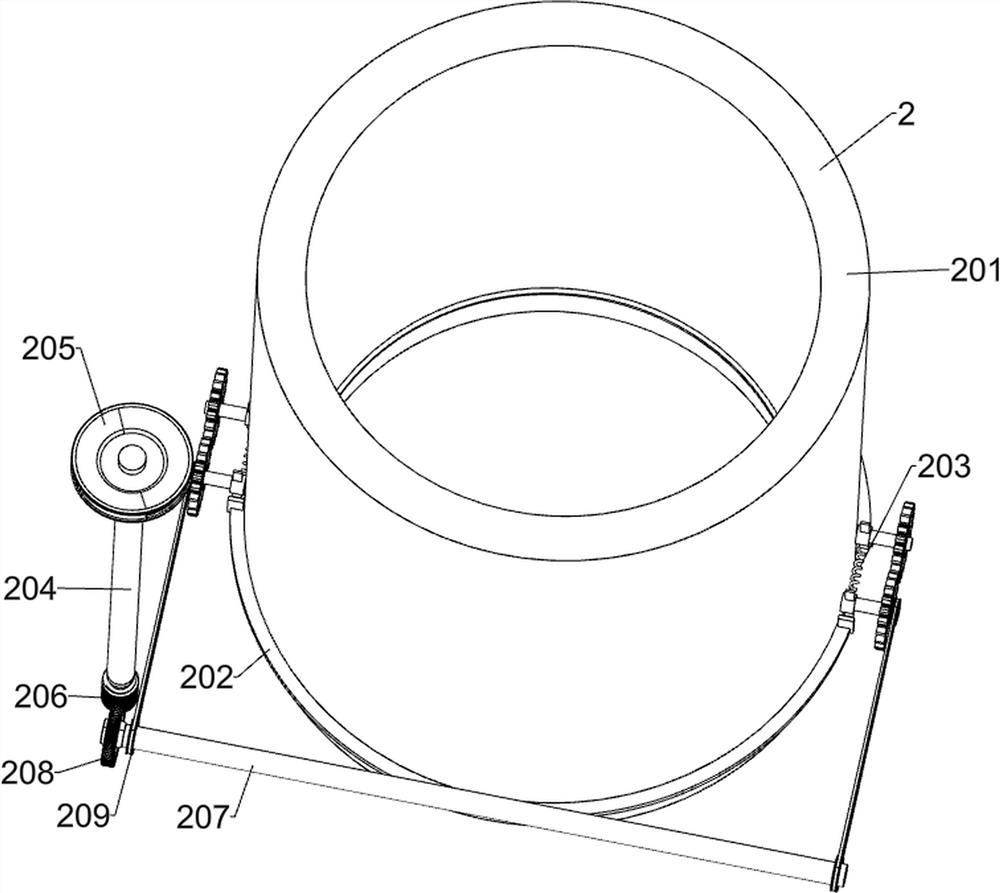

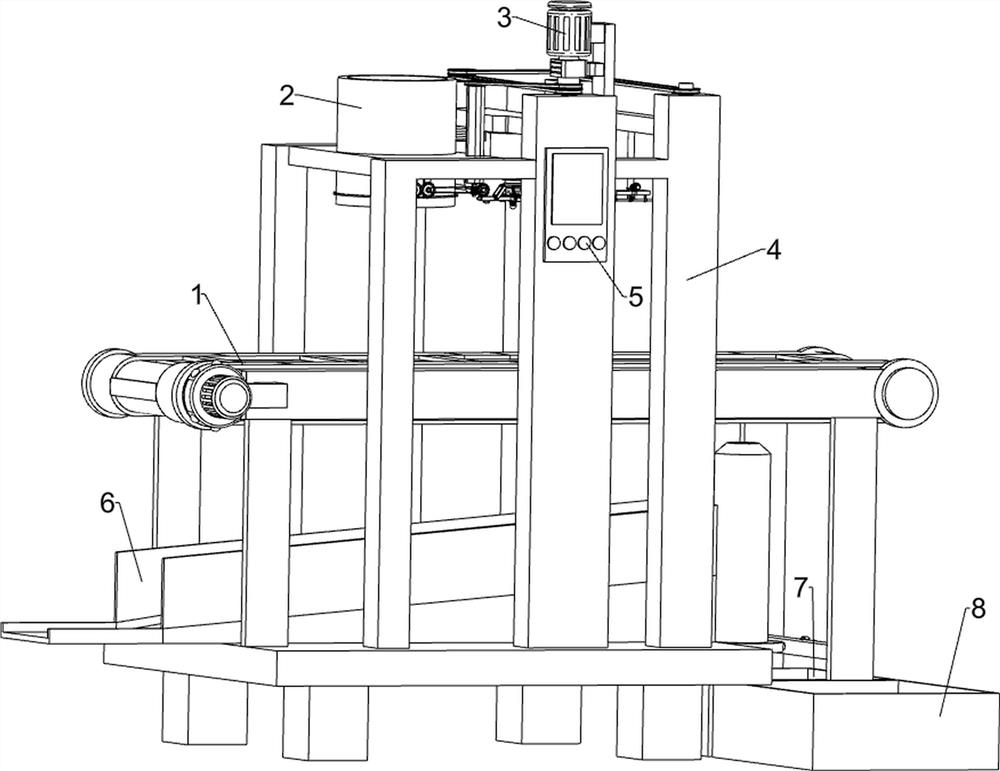

[0035] A fire extinguisher bottom plate installation and correction integrated device, such as Figure 1-14 As shown, it includes a conveying assembly 1, a material conveying assembly 2, an installation assembly 3, a support platform 4, a console 5, a collection ramp 6, a first collection box 7 and a second collection box 8; the transmission assembly 1 and the support platform 4 connected; support platform 4 is connected with material delivery assembly 2; material delivery assembly 2 is connected with installation assembly 3; installation assembly 3 is connected with support platform 4; console 5 is connected with support platform 4; The support platform 4 is connected; the first collection box 7 is connected with the support platform 4 ; the second collection box 8 is connected with the support platform 4 .

[0036] Working process: When in use, first place the device and keep the support platform 4 stable, connect the external power supply, control the control console 5 to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com