A solvent-free phenolic epoxy coating

A phenolic epoxy and phenolic epoxy technology, applied in the field of coatings, can solve the problems of non-compliance with environmental protection requirements, low qualification rate, under-sulfur of rubber sheets, etc., to overcome the complex vulcanization process of rubber lining, ensure long-life use, excellent The effect of chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

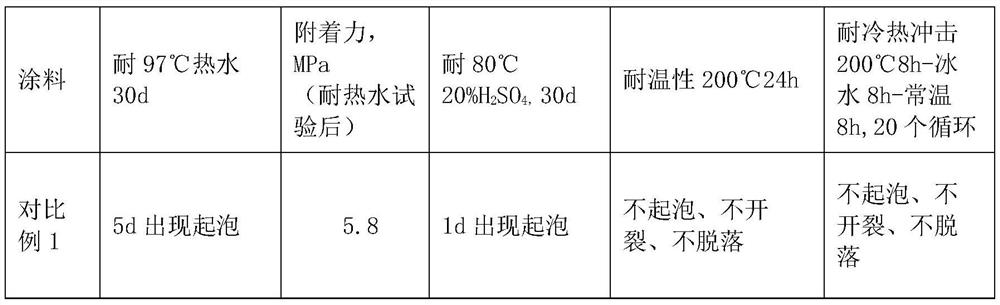

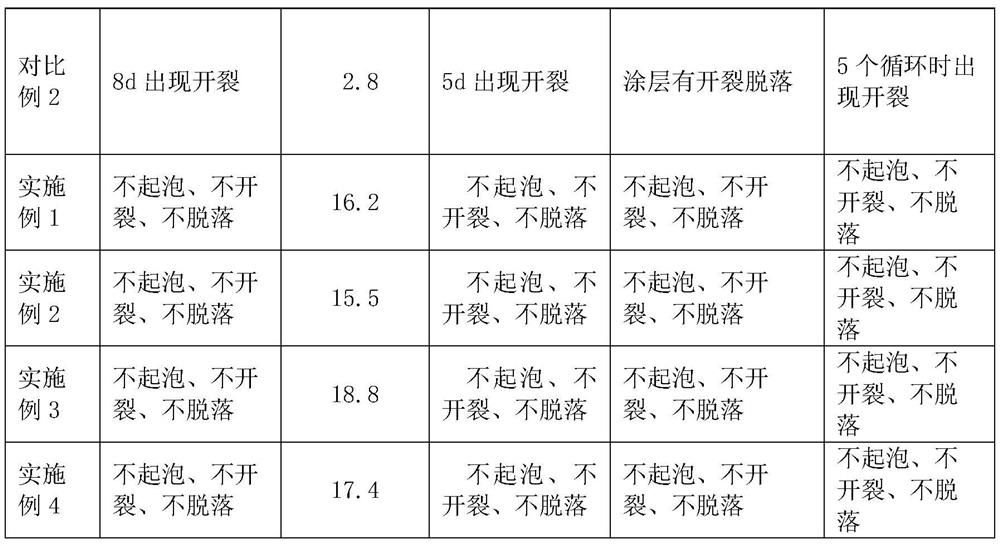

Examples

preparation example Construction

[0029] The preparation method of component A is as follows: adding each component into a stainless steel barrel, dispersing and mixing at a high speed, and then obtaining.

[0030] The preparation method of component B is as follows: adding each component into a stainless steel barrel, stirring and heating to 100° C. for 2-4 hours, and then obtaining.

Embodiment 1

[0032] A solvent-free phenolic epoxy coating, comprising component A and component B, component A includes 38 parts by mass of phenolic epoxy resin, 15 parts of bisphenol A epoxy resin E51, 15 parts of mica iron oxide, and talc 15 parts of powder, 15 parts of quartz powder, 2 parts of additives, the additives are defoamer and anti-settling agent. Component B is 65 parts of isophorone diamine, 12 parts of tertiary glycidyl carbonate, 8 parts of dibutyl phthalate and 8 parts of dioctyl phthalate, and 7 parts of salicylic acid. The solvent-free phenolic epoxy liquid coating can be obtained after the A component and the B component are mixed. During construction, the dosage ratio of component A and component B is 100:18 by mass.

Embodiment 2

[0034] A solvent-free liquid phenolic epoxy coating, comprising component A and component B, component A includes 30 parts by mass of phenolic epoxy resin, 30 parts of bisphenol A epoxy resin E51, 10 parts of mica iron oxide, 18 parts of talcum powder, 10 parts of precipitated barium sulfate, 2 parts of auxiliary, defoamer and anti-settling agent. Component B is 60 parts of isophorone diamine, 15 parts of glycidyl tertiary carbonate, 15 parts of dibutyl phthalate, and 10 parts of salicylic acid. The solvent-free liquid phenolic epoxy coating can be obtained after the A component and the B component are mixed. During construction, the dosage ratio of component A and component B is 100:22 by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com