Heat exchanger for air conditioner

A technology for air conditioners and heat exchangers, which is used in heat exchange equipment, air conditioning systems, space heating and ventilation, etc., and can solve the problems of increased heat transfer effect, reduced heat transfer performance, and increased heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Next, an embodiment of the heat exchanger for an air conditioner of the present invention will be described in detail with reference to the accompanying drawings.

[0015] In the drawings, the same names and symbols are given to the same components as the conventional ones, and detailed description is omitted.

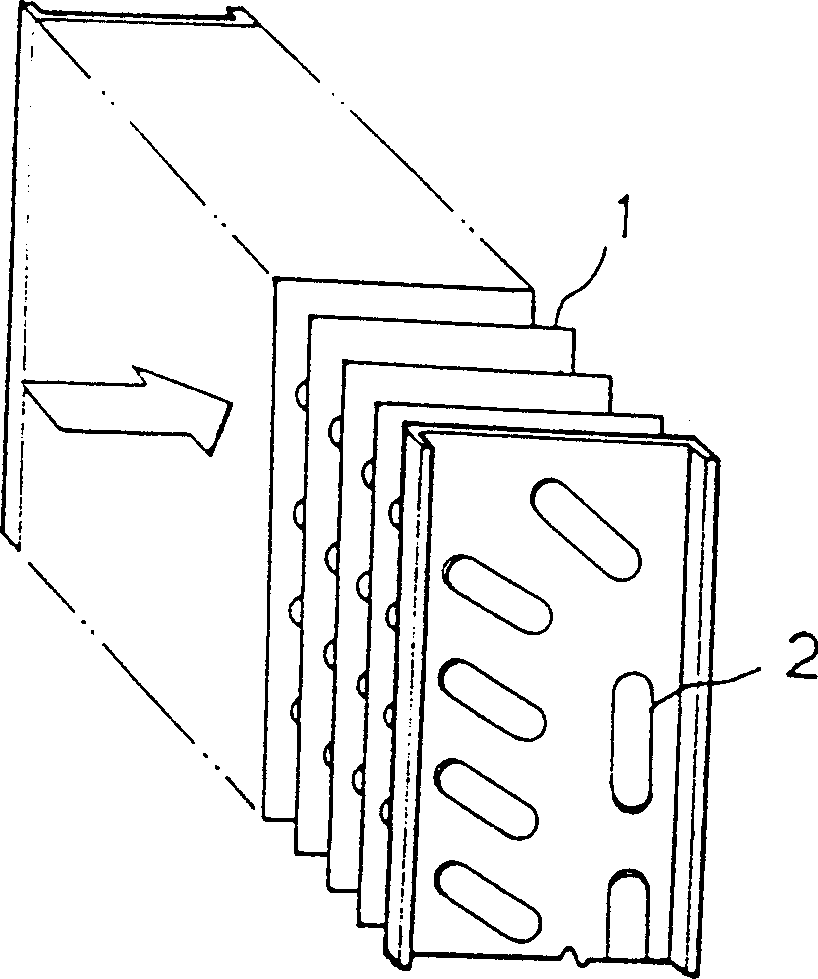

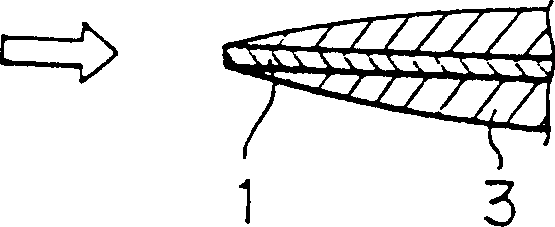

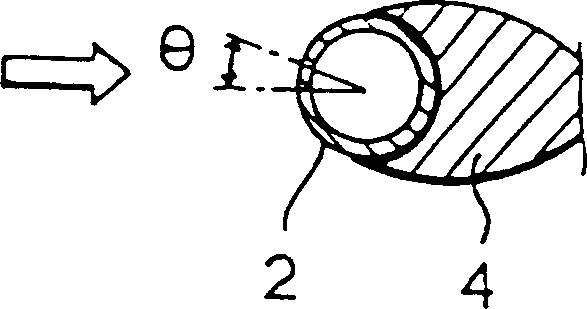

[0016] The heat exchanger of the air conditioner of an embodiment of the present invention is made up of the following parts as shown in Figure 6: air flows therebetween, mutually becomes predetermined space, a plurality of flat fins 1 of parallel arrangement; The flat heat sink 1 is staggered up and down and inserted into the configuration at right angles, and there are heat transfer tubes 2 for fluid flow inside; A plurality of first slot-type louver groups 20a, 20b respectively arranged on the back side and the surface of the flat fin 1 on the front side of the heat transfer tube 2; The turbulent airflow diffused by the slot-type louver groups 20a, 20b cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com