Full-automatic combined multi-frequency ultrasonic vacuum cleaning and drying device and using method thereof

A multi-frequency ultrasonic and vacuum cleaning technology, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, drying, etc., can solve the problems such as stains or metal shavings that are difficult to remove, and achieve convenient operation, clean cleaning and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

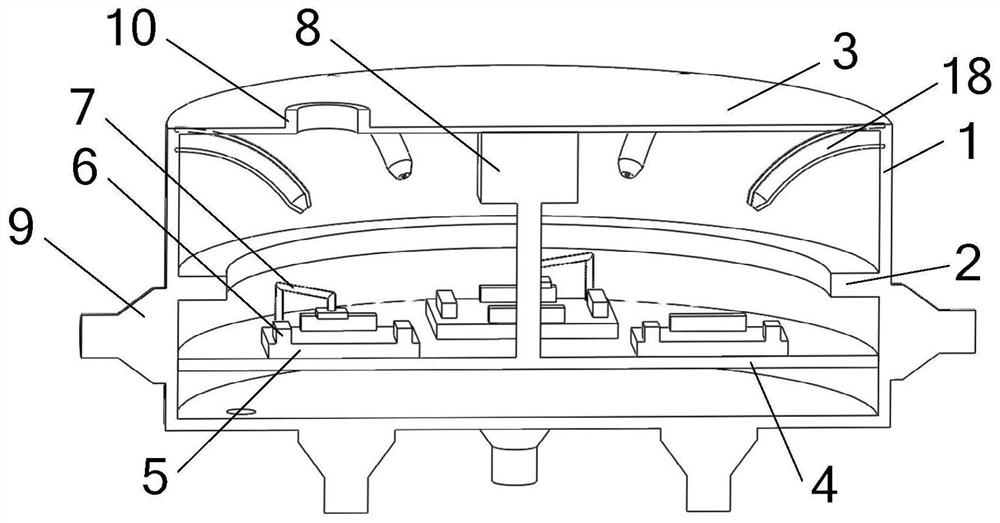

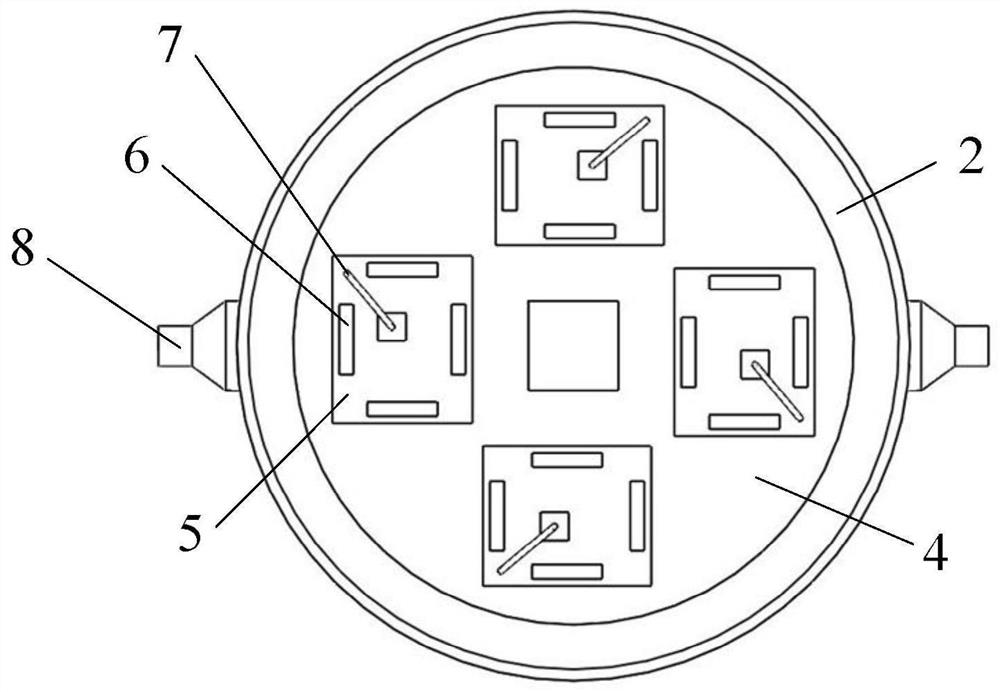

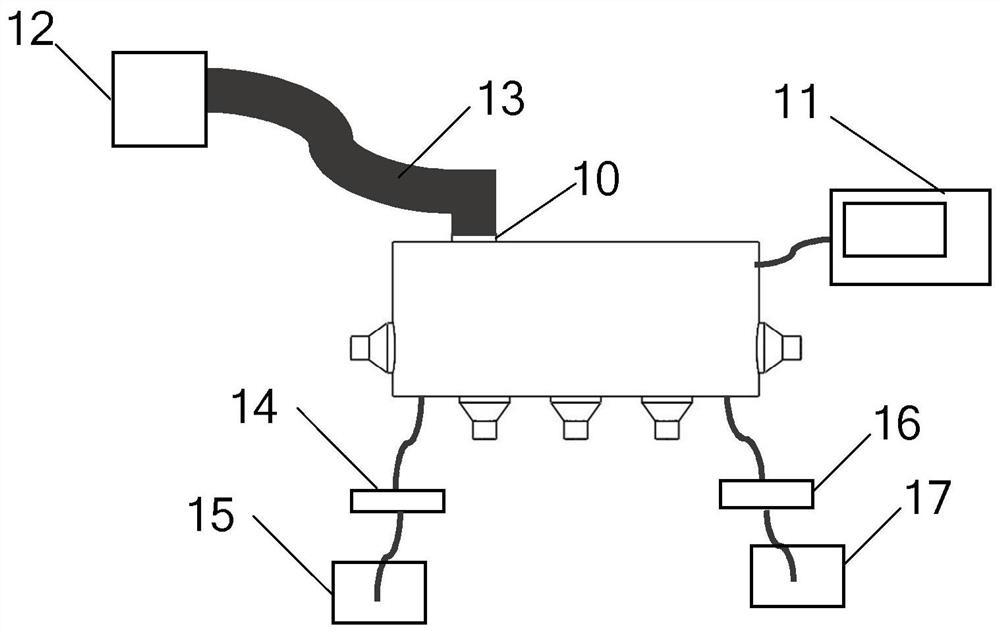

[0028] Such as figure 1 , 2 As shown in and 3, the fully automatic combined multi-frequency ultrasonic vacuum cleaning and drying device includes a working tank 1, a sealing ring 2, a sealing cover 3, a stage 4, a heating element 5, a low-frequency vibration element 6, a clamp 7, and a linear motion Mechanism 8 and ultrasonic transducer 9; the inner wall of the working tank 1 is provided with an annular groove, and a sealing ring 2 is arranged in the annular groove; the top of the working tank 1 is detachably connected (such as a buckle or screw) with a sealing cover 3; The platform 4 and the inner wall of the working tank 1 form a sliding pair, and are located under the sealing ring 2; the top surface of the stage 4 is fixed with a plurality of heating elements 5 uniformly distributed along the circumferential direction, and each heating element is fixed with a low-freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com