Hot-pressing sealing machine

A sealing machine and sealing technology, applied in packaging machines, packaging sealing/fastening, transportation packaging, etc., can solve the problems of uncontrollable sealing quality, easy fluctuation of heat sealing temperature, and no sealing at the sealing place, so as to achieve effective control The effect of quality assurance, simple and reliable movement mechanism, and fast action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

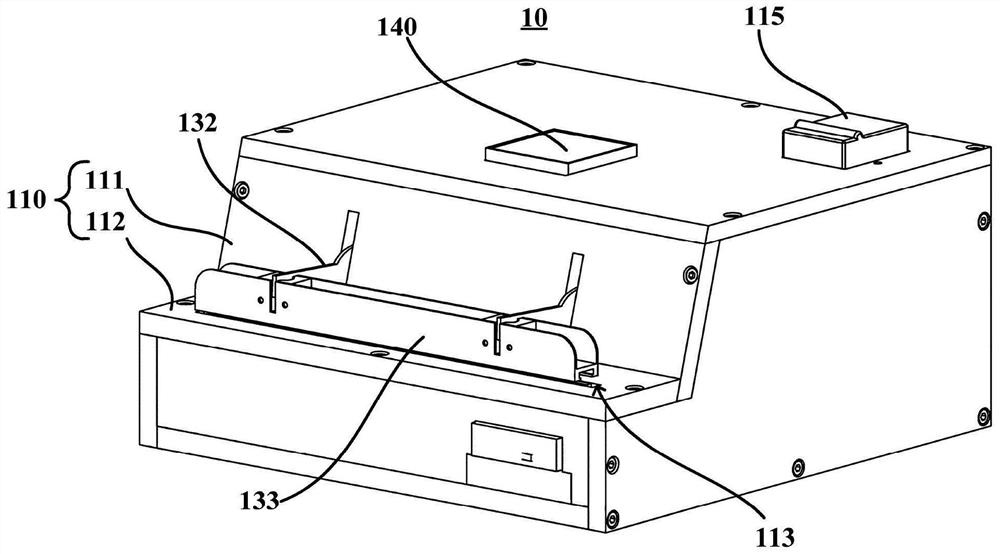

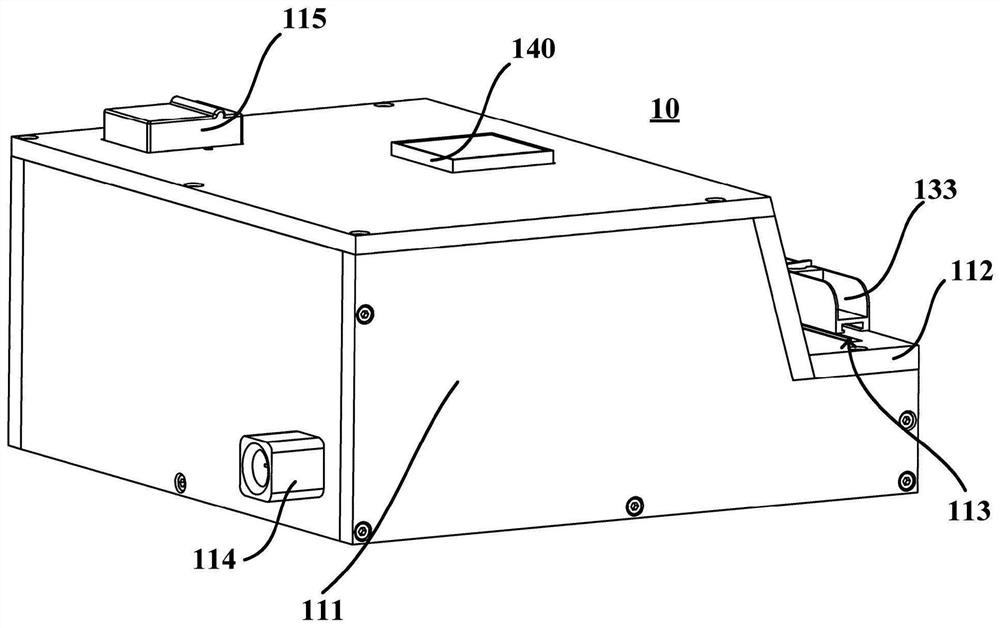

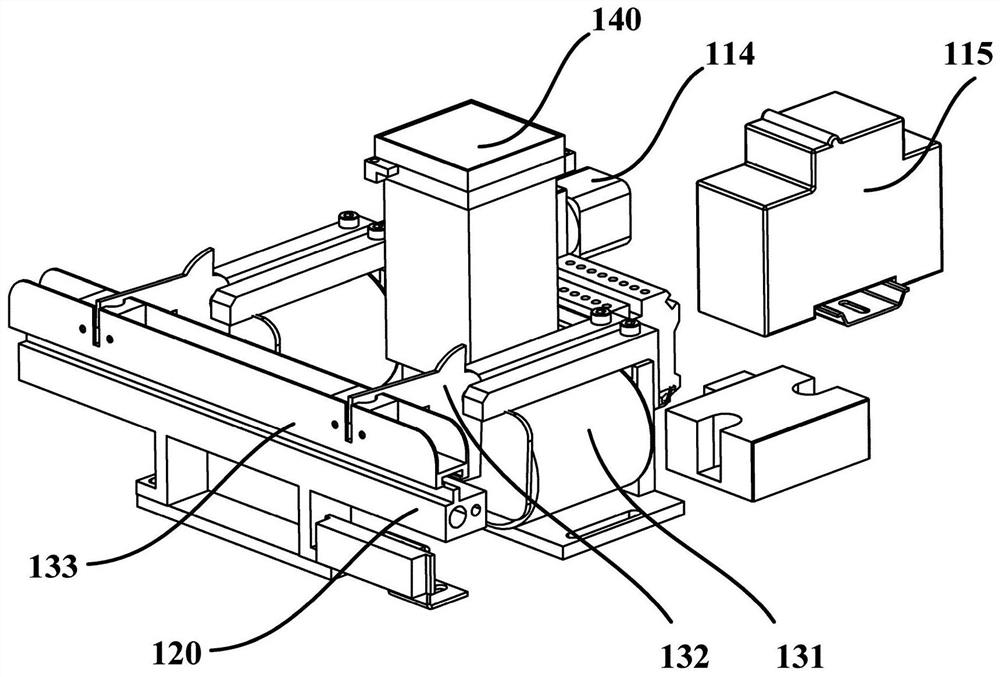

[0042] figure 1 is a perspective view of a heat press sealing machine 10 according to an embodiment of the present invention, figure 2 is a schematic diagram of another angle of the heat press sealing machine 10 according to an embodiment of the present invention, image 3 is a schematic diagram of the internal components of the heat press sealer 10 according to one embodiment of the present invention. The heat-press sealing machine 10 of this embodiment may generally include: a casing 110 , a first heat-press assembly 120 , an electromagnetic drive device 131 , a lifting swing arm 132 , and a second heat-press assembly 133 .

[0043] The casing 110 can be made of fiberglass material, and specifically includes a main body 111 and a hot pressing table 112 located in front of the main body 111 , wherein an opening 113 is opened on the top surface of the hot pressing table 112 . The height of the main body part 111 is higher than that of the heat-pressing table part 112, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com