High-corrosion-resistance stainless steel and manufacturing method thereof

A stainless steel, corrosion-resistant technology, applied in the field of high-corrosion-resistant stainless steel production, can solve the problem that the lid of the thermos cup is not easy to unscrew, and achieve the effect of avoiding excessive internal pressure, saving process and cost, and avoiding difficulty in opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of corrosion resistance stainless steel is as follows:

[0051] S1: Weigh the corresponding ratio of the corresponding ratio in the above-mentioned material group 2, and add it to the high temperature arc furnace, melting, the melting temperature is 1570-1630 ° C, then the steel water temperature is heated to 1630 -1690 ° C, the corresponding components are added, and the steel water is refined in the steel baffle. After refining, it is placed in a vacuum degassing apparatus for degassing treatment, and the absolute pressure in the vacuum degassing device is less than 70Pa. The holding time is 15-20 min;

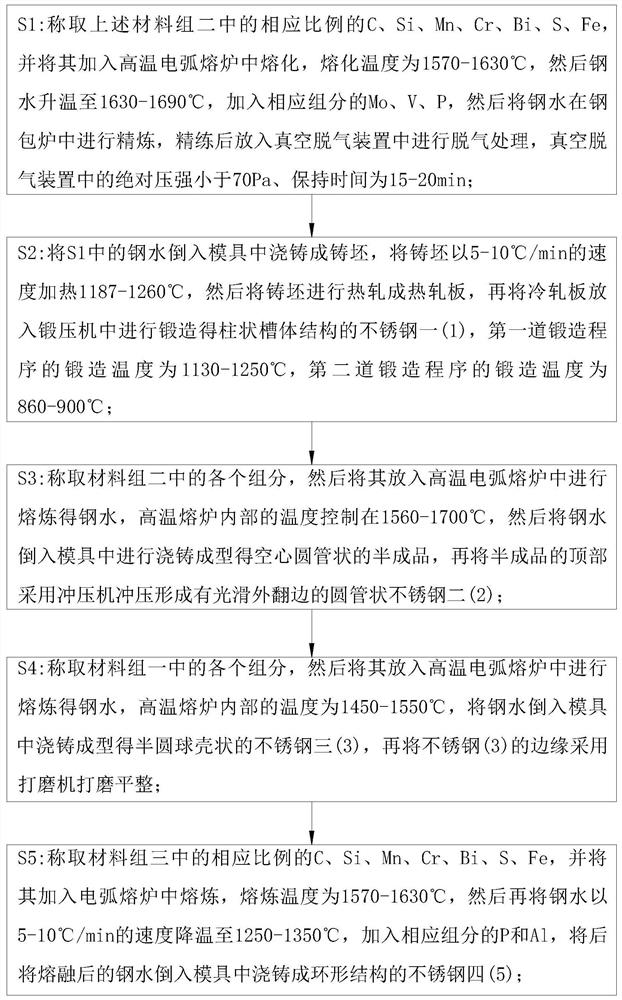

[0052] S2: Pour the steel water in S1 into the mold to cast into a slab, heat 1187-1260 ° C at 5-10 ° C / min, then heat rolled into a hot rolled sheet, and then cold rolling The plate is placed in the forging machine forging the stainless steel of the columnar groove structure, the forging temperature of the first forging program is 1130-1250 ° C, ...

Embodiment approach

[0060] As an embodiment of the present invention, the inner wall of the first annular connection groove 4 is uniformly provided with convex thorn 11; the convex thorn 11 is composed of a material group; when operating, injecting the first annular connection groove 4 inside The connection steel water will be integrally formed with the convex thorn 11 in the inner wall of the first annular connection groove 4, which in turn has a more secure connection of the inner wall of the steel water to the first annular connection groove 4, further increases the first annular shape. The connection intensity and anti-drawing of the connecting groove 4 and the stainless steel four 5 are connected.

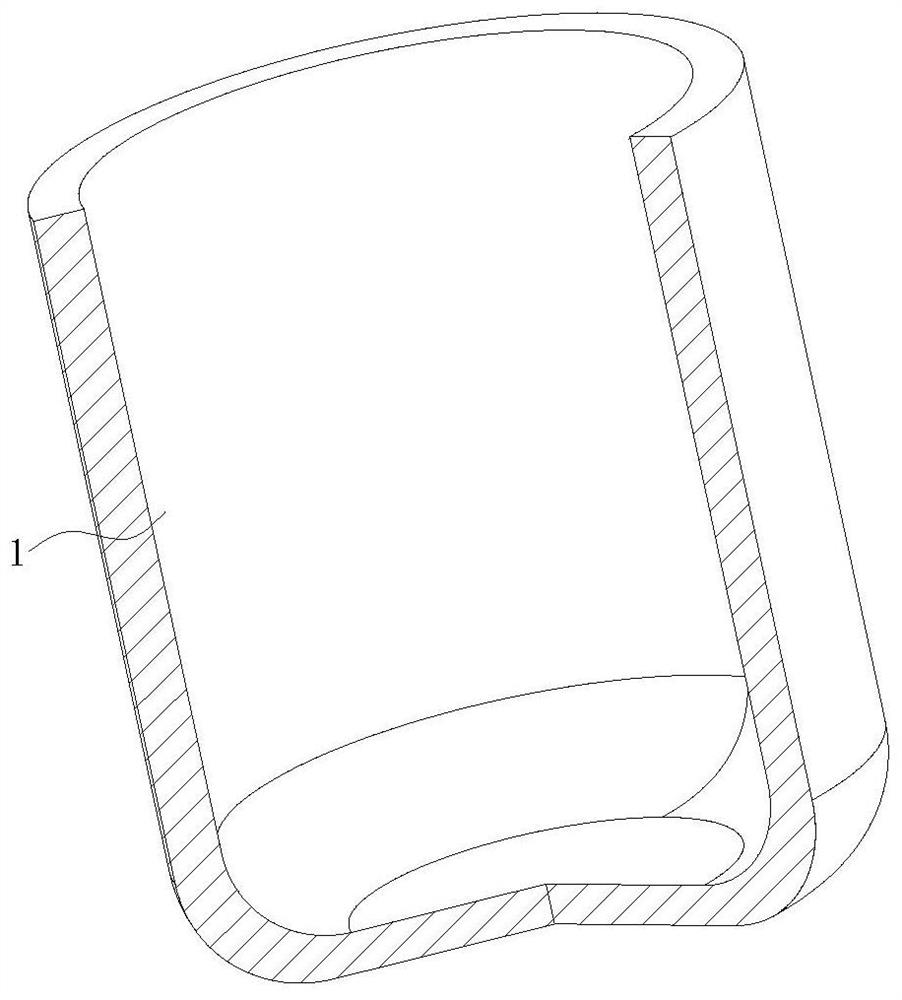

[0061] As an embodiment of the present invention, the bottom edge of the stainless steel 2 2 and the top edge of the stainless steel one 3 are opened with a second annular connection groove 8 associated with two sets of first annular connecting grooves 4; the second annular shape The connecting groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com