A compound machine dust removal device and its process

A technology of dust removal device and compound machine, which is applied in the directions of mechanical cleaning, transportation and packaging, separation methods, etc., can solve the problems of raised surface of the fabric and insufficient compounding of the fabric, so as to reduce impurities, facilitate collection, and improve the effect of impurity removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

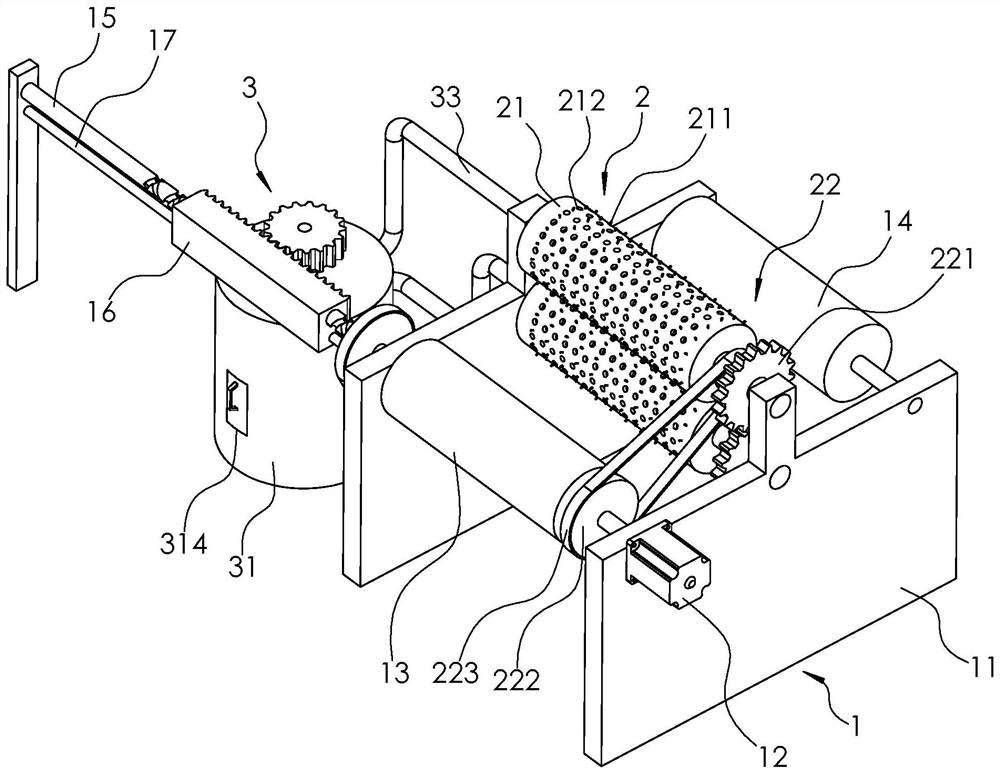

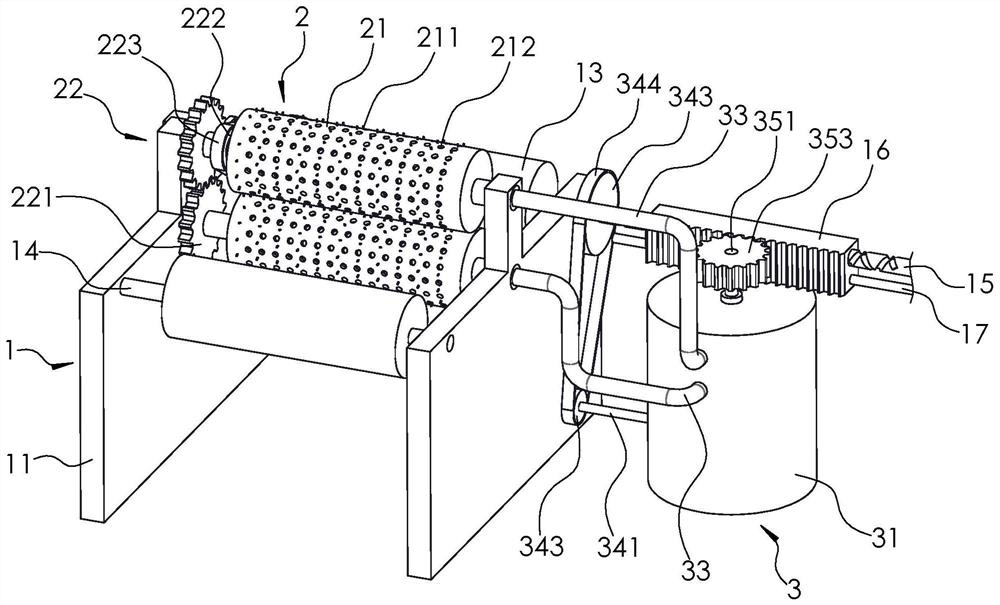

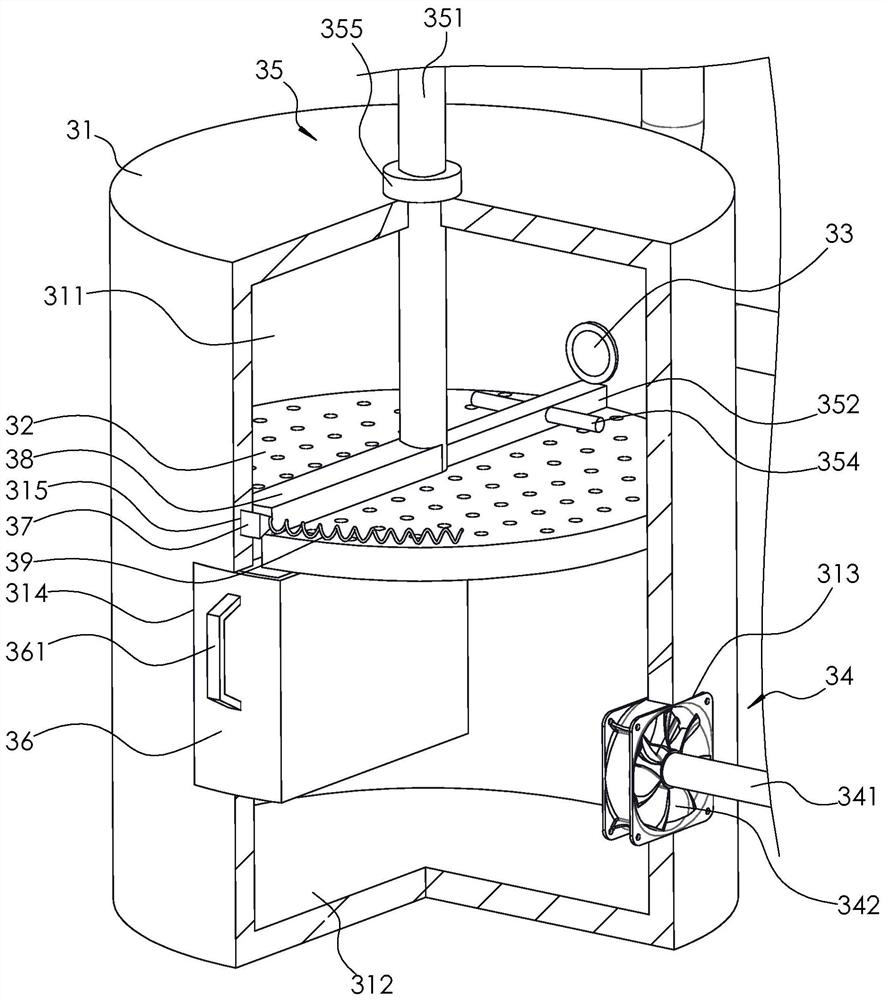

[0035] The following is attached Figure 1-4 The application is described in further detail.

[0036] The embodiment of the present application discloses a compound machine dust removal device. Such as figure 1 As shown, a compound machine dust removal device includes a conveying mechanism 1, a cleaning mechanism 2 and a miscellaneous suction mechanism 3; the conveying mechanism 1 is used to convey fabrics, and the cleaning mechanism 2 is used to clean impurities on the fabric during conveying, and the miscellaneous mechanism 3 is used to collect the impurities cleaned by the cleaning mechanism 2.

[0037]The conveying mechanism 1 comprises a support 11 and a motor 12, and the support 11 is rotatably connected with an unwinding roller 13 and a conveying roller 14 arranged horizontally, and the unwinding roller 13 and the conveying roller 14 are coaxially arranged; the motor 12 is fixed on the support 11 , the output shaft of the motor 12 is fixedly connected to the unwindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com