Efficient painting device for building wall

A high-efficiency, wall-mounted technology, applied in the direction of construction and building structure, can solve the problems of inconvenient handling, large size of the device, and difficulty in painting the building walls, and achieve the effect of improving the painting effect and the convenient transportation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

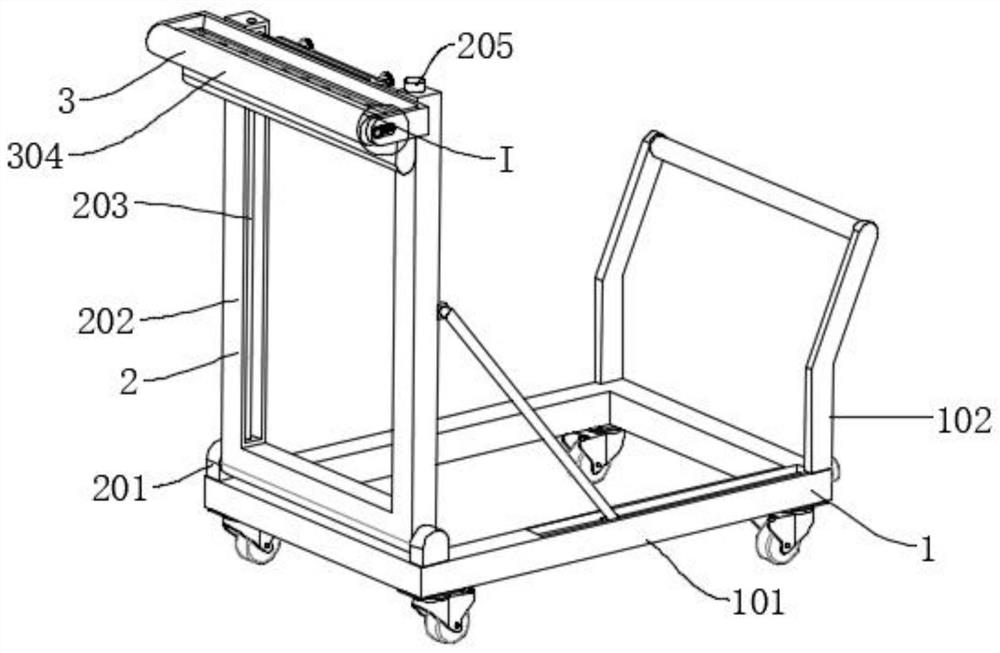

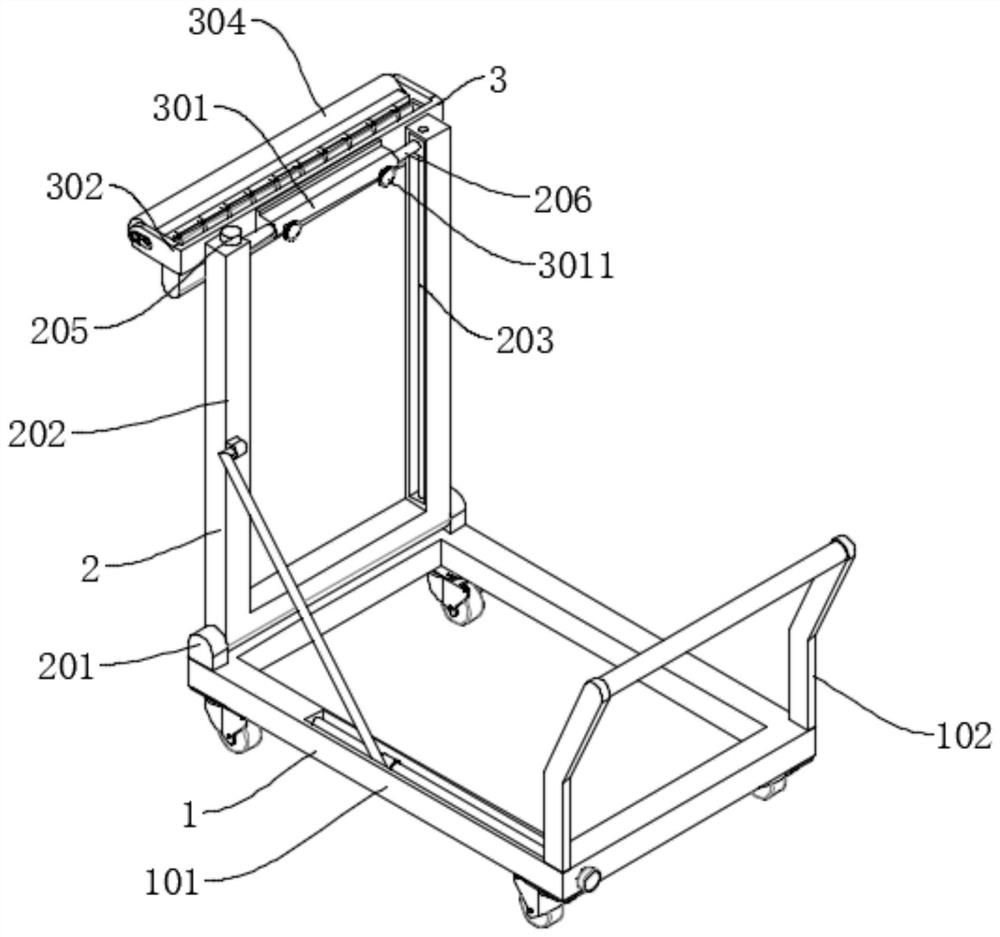

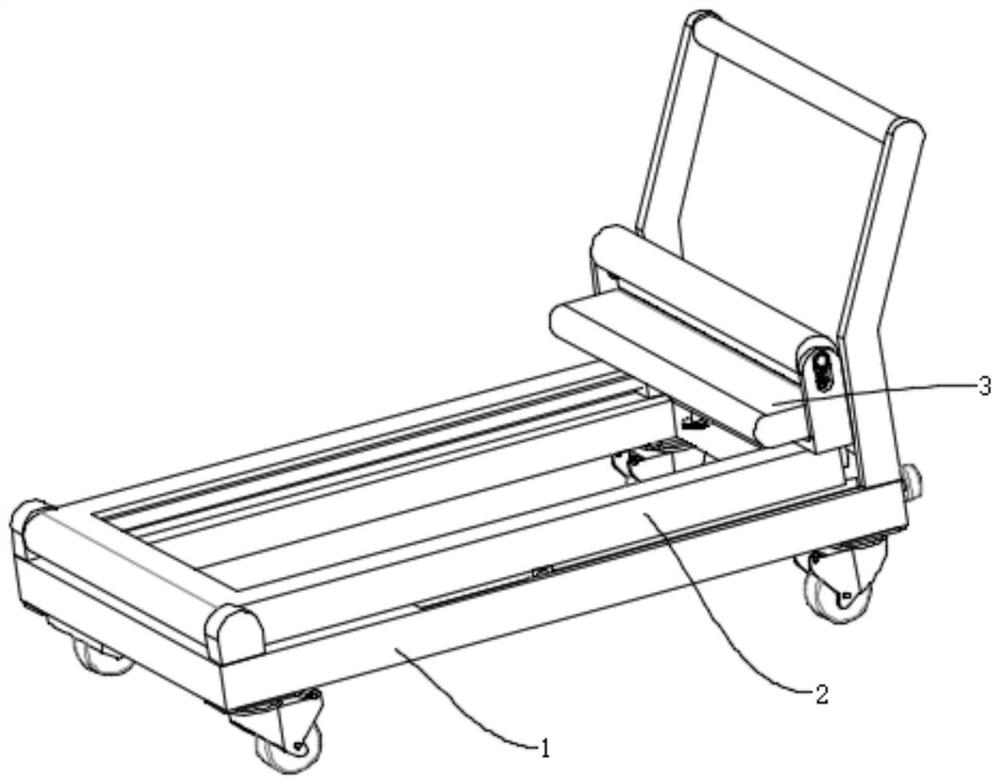

[0039] Such as Figure 1-Figure 9 As shown, the present invention is used for a high-efficiency painting device for building walls, including a moving mechanism 1 , a folding mechanism 2 and a painting mechanism 3 . One side of the moving mechanism 1 is provided with a folding mechanism 2 , and the side of the folding mechanism 2 away from the moving mechanism 1 is rotatably connected with a painting mechanism 3 .

[0040]Described folding mechanism 2 comprises rotating base 201, support 202, stabilizing bar 203, the first transmission screw 204, motor 205 and moving rod 206, rotating base 201 is connected to moving mechanism 1 top front side two ends by bolt, rotating base 201 A support 202 is connected between them through the damping rotation of the pin shaft, and the support 202 is a U-shaped structure. The inner side of one of the columns of the bracket 202 is provided with a first chute, the inner side of the first chute is connected with the first transmission screw 20...

Embodiment 2

[0048] Such as Figure 10 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the support mechanism 4 includes a second support rod 41, a second fixed block 42, and a slot 43, the slot 43 is set on the top of the flatbed truck 101, and the inside of the slot 43 is snapped There is a second support rod 41, and the end of the second support rod 41 away from the draw-in groove 43 is provided with an elbow, which is inserted into the inner side of the second fixed block 42, and the second fixed block 42 is welded on the bracket 202, so that the In order to support the function of the bracket 202, when one end of the second support rod 41 is plugged into the inner side of the second fixing block 42 and the other end is engaged in the inner side of the slot 43, the bracket 202 is in a vertical state.

[0049] In the above structure, when in use, first move the device to a suitable position, then rotate the bracket 202 so that the bracket 202 is in a vertical stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com