A Highly Sensitive Humidity Detector

A humidity detector and sensitive technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high cost and large size of humidity detection devices, and achieve high humidity detection sensitivity and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

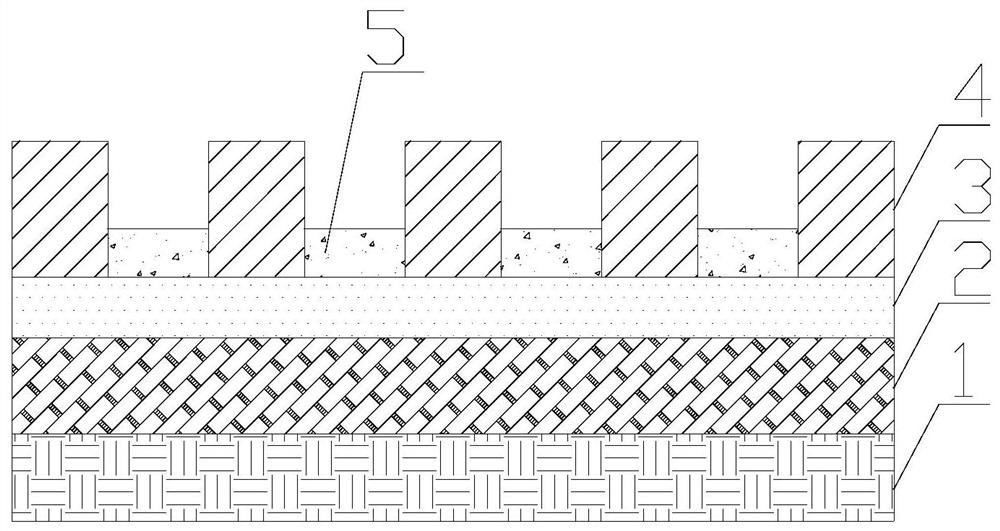

[0021] The invention provides a highly sensitive humidity detector, such as figure 1 As shown, it includes an antiferromagnetic layer 1 , a pinning layer 2 , a barrier layer 3 , a free layer 4 , and a hygroscopic expansion material part 5 . The material of the antiferromagnetic layer 1 is a hard magnetic antiferromagnetic material, specifically, the material of the antiferromagnetic layer 1 is IrMn, PtMn, FeMn. The pinning layer 2 is placed on the antiferromagnetic layer 1 . The material of the pinning layer 2 is a metal or semi-metal with high spin polarizability, specifically, the material of the pinning layer 2 is Co, Fe, CoFe, CoFeB, CoFeAl alloy. The barrier layer 3 is placed on the pinning layer 2 . The material of the barrier layer 3 is aluminum oxide or magnesium oxide. The free layer 4 is placed on the barrier layer 3 . The barrier layer 3 separates the pinned layer 2 and the free layer 4 . The material of the free layer 4 is soft magnetic material with weak magn...

Embodiment 2

[0025] On the basis of Example 1, such as figure 1 As shown, the hygroscopic swelling material portion 5 is in contact with the free layer 4 . In this way, when the hygroscopic expansion material part 5 expands, it will also squeeze the free layer 4, thereby changing the stress in the free layer 4, thereby changing the spin state of the free layer 4, thereby changing the magnetoresistance of the magnetic tunnel junction. Therefore, this embodiment can realize humidity detection with higher sensitivity.

Embodiment 3

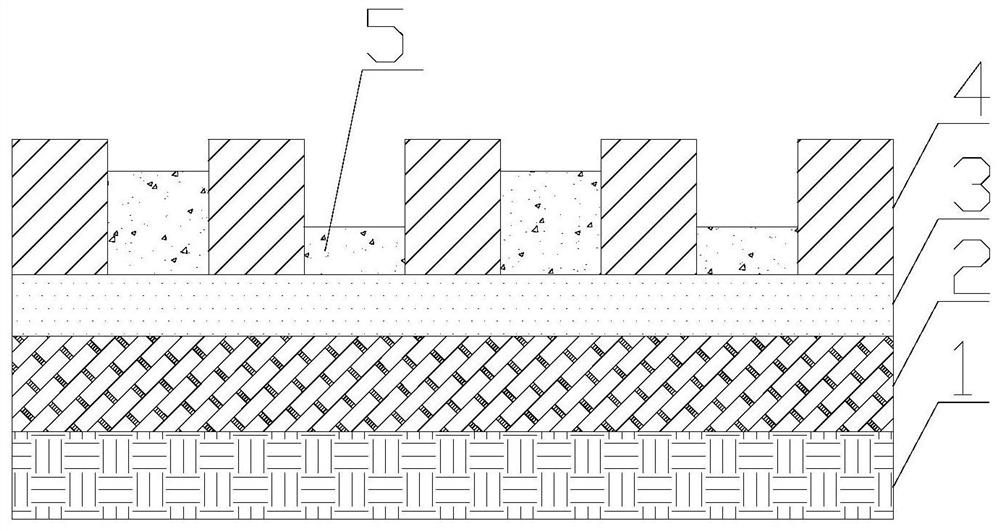

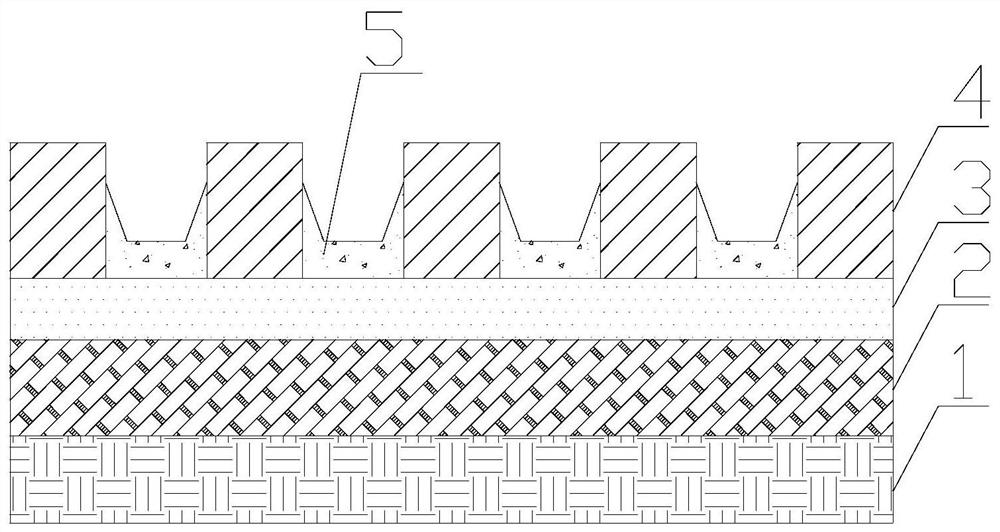

[0027] On the basis of Example 2, such as figure 2 As shown, in adjacent holes, the heights of the hygroscopic expansion material parts 5 are different. In this way, the compressive forces exerted by the hygroscopic expansion material parts 5 in adjacent holes on the free layer 4 are different, thereby causing the effect of twisting stress on the free layer 4, thereby changing the spin in the free layer 4 more. state, thereby changing the magnetoresistance of the magnetic tunnel junction more, thereby achieving higher sensitivity humidity detection.

[0028] Furthermore, the holes are arranged non-periodically. That is, the distances between the holes are not equal. In this way, it is easier to cause inhomogeneous stress distribution inside the free layer 4, thereby changing the spin state of the free layer 4 more, thereby changing the magnetoresistance of the magnetic tunnel junction more, thereby achieving higher sensitivity to humidity probing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com