Floor brush and cleaning machine

A ground brush seat and rolling brush technology, which is applied in the direction of cleaning machinery, carpet cleaning, floor cleaning, etc., can solve the problems of residual water stains on the ground, long drying time, wet ground, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

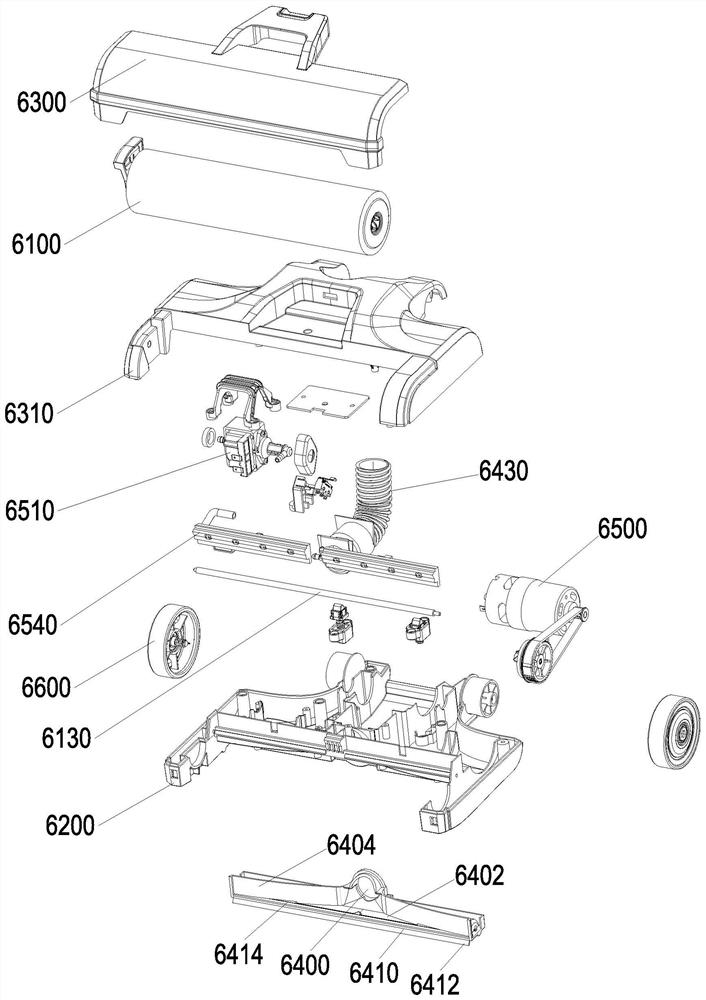

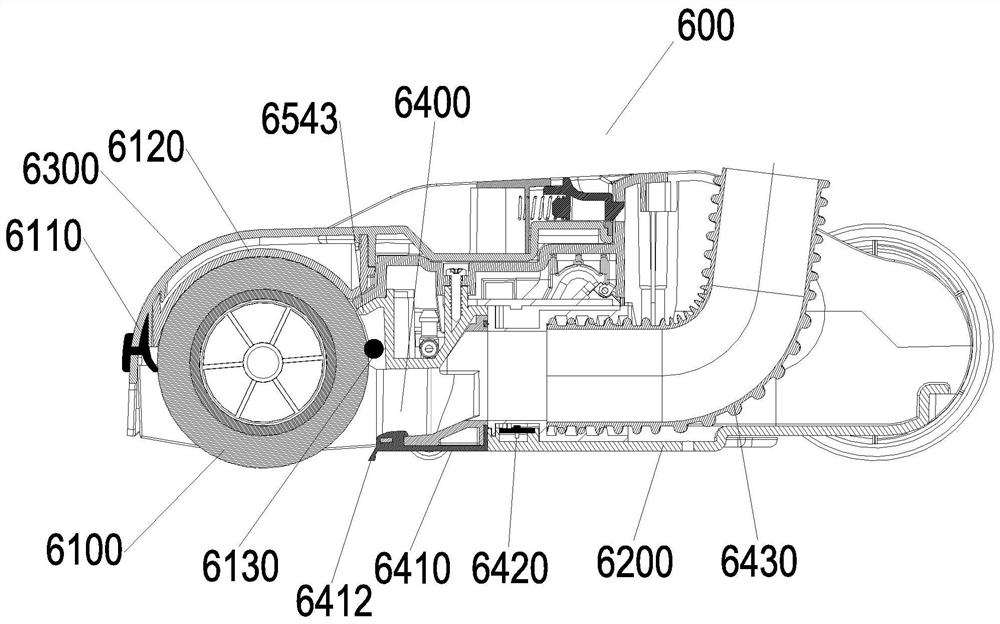

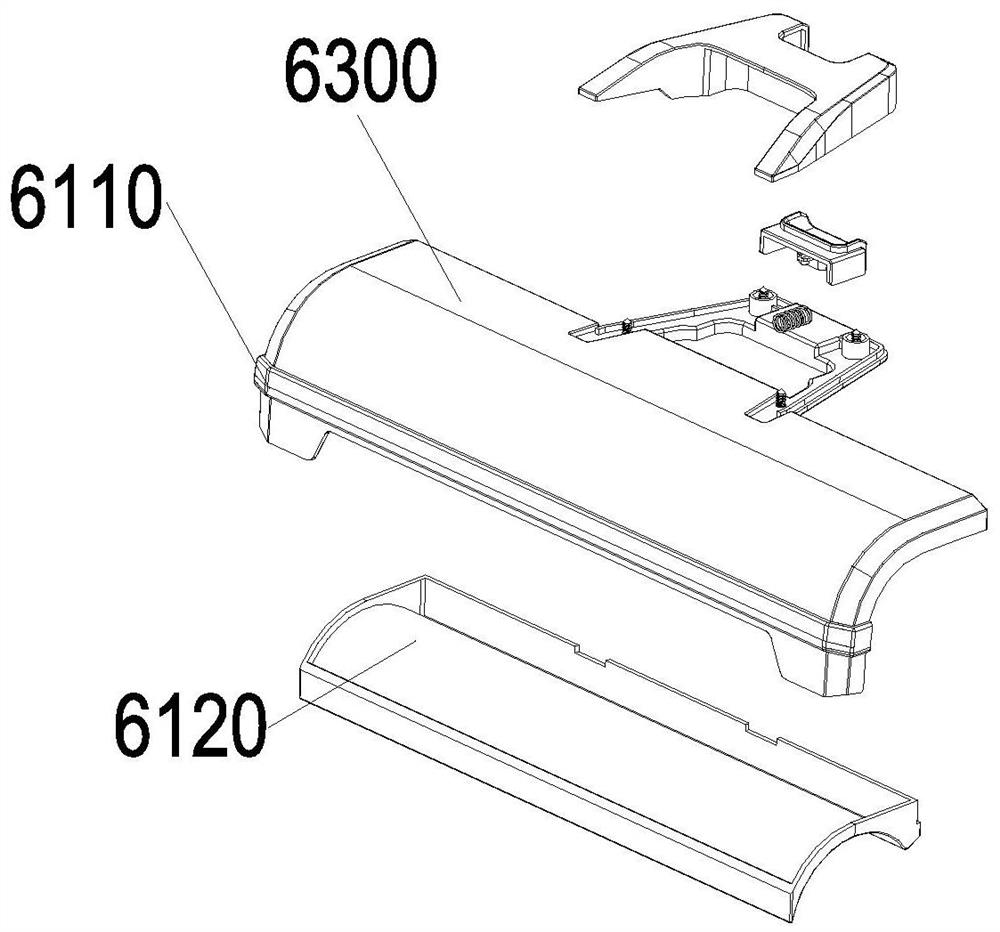

[0027] Example: such as Figure 1-7 As shown, the present invention discloses a first embodiment of a ground brush, which includes a rolling brush body 6100, a ground brush seat 6200 at least partially containing the bottom of the rolling brush body 6100, and a ground brush cover 6310 at least partially containing the top of the rolling brush body 6100 , the cleaning member 6110 that is arranged at the front end of the roller brush body 6100 and can flexibly contact the roller brush body, the roller brush cover 6300 that is detachably connected with the floor brush cover 6310 and at least partially covers the roller brush body 6100, is located above the extrusion member 6130 and is in contact with the roller brush body The inner liner 6120 integrally formed inside the ground brush cover 6310 or the rolling brush cover 6300, the extrusion part 6130 arranged at the rear end of the rolling brush body 6100 and rigidly contacting the rolling brush body 6100, located between the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com