A flexible mold applied to creep aging forming and creep aging forming method

A creep aging forming, flexible mold technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost, low production efficiency, low mold applicability, etc., to facilitate adjustment, avoid instability, The effect of improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

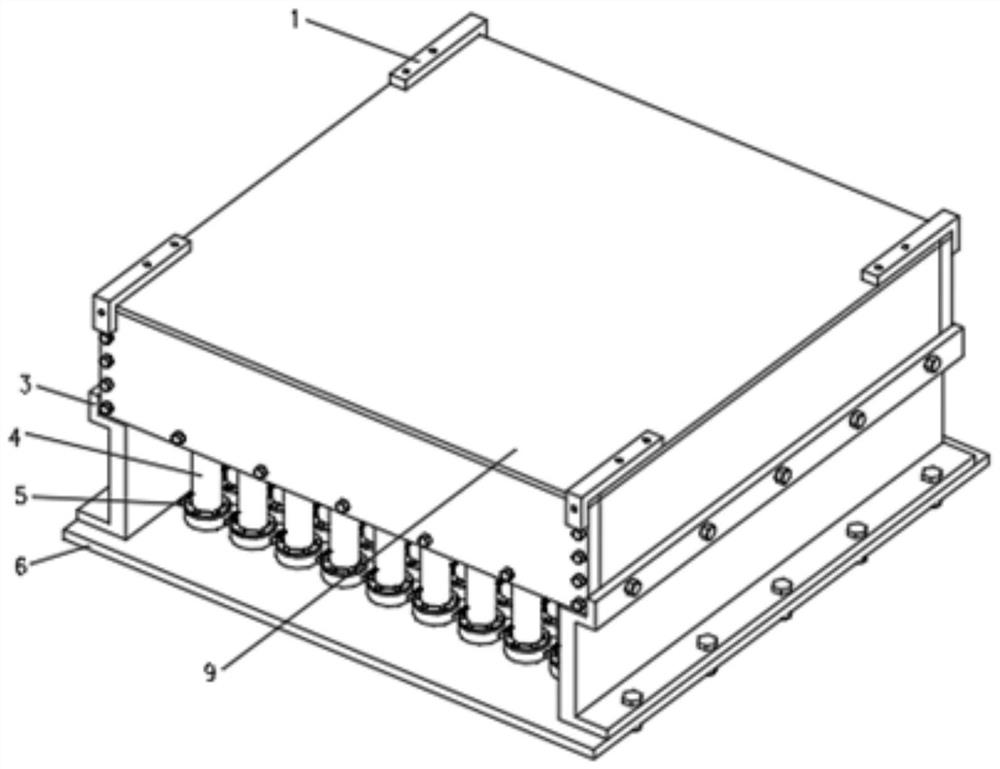

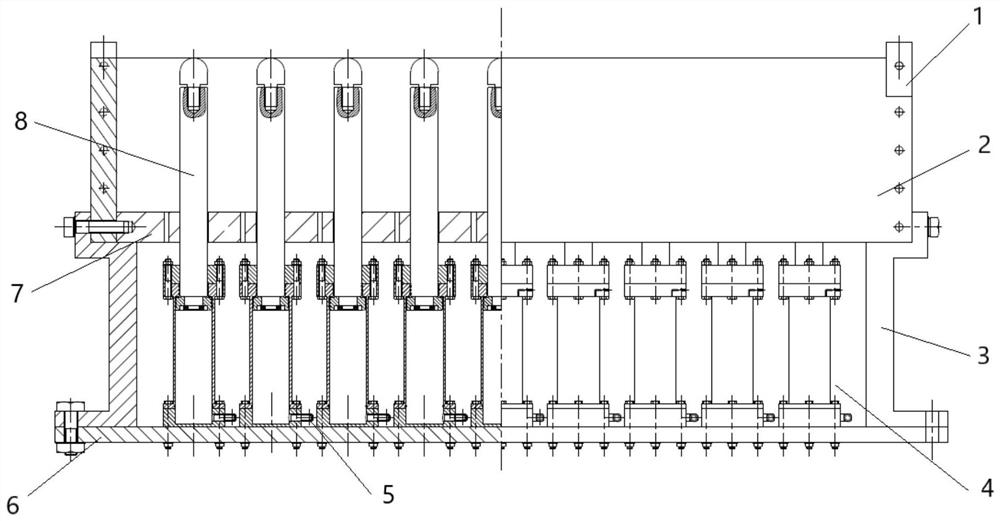

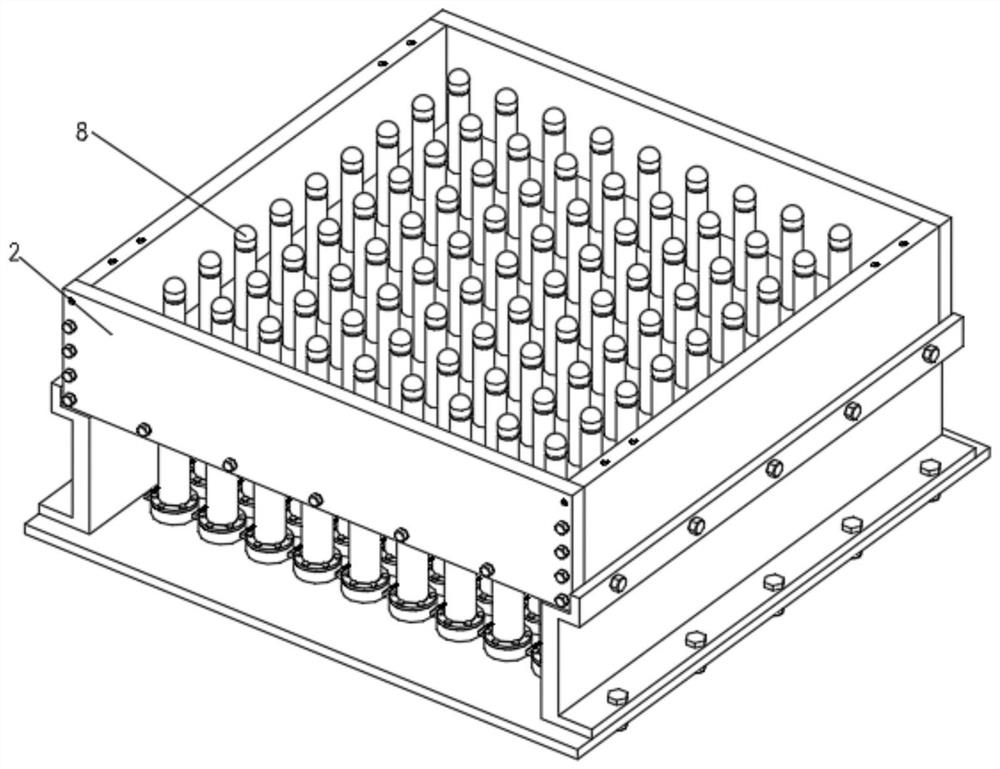

[0040]A flexible mold for creep aging forming according to the present invention, comprising edge holder 1, unit body 8, side wall 2, fixing plate 7, hydraulic cylinder 4, base 6, bracket 3, hydraulic control system, hydraulic oil Take over 5,

[0041] The bracket 3 and a plurality of hydraulic cylinders 4 distributed in a dot matrix are all arranged on the base 6, the bracket 3 is arranged on the outer periphery of the hydraulic cylinder 4, and four side walls 2 are erected on the bracket 3 in a rectangular shape, The fixed plate 7 is horizontally arranged on the bracket 3, and the fixed plate 7 is provided with a through hole corresponding to the position of the hydraulic cylinder 4. The unit body 8 includes a unit body body and a spherical end, and the unit body body matches through the fixed plate 7. The through hole opened, the lower end of the main body of the unit is connected with the piston of the hydraulic cylinder 4, and the edge strip 1 is arranged on the four side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com