Vehicle bottom plate structure

A base plate and vehicle technology, applied in vehicle energy storage, vehicle components, vehicles for freight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

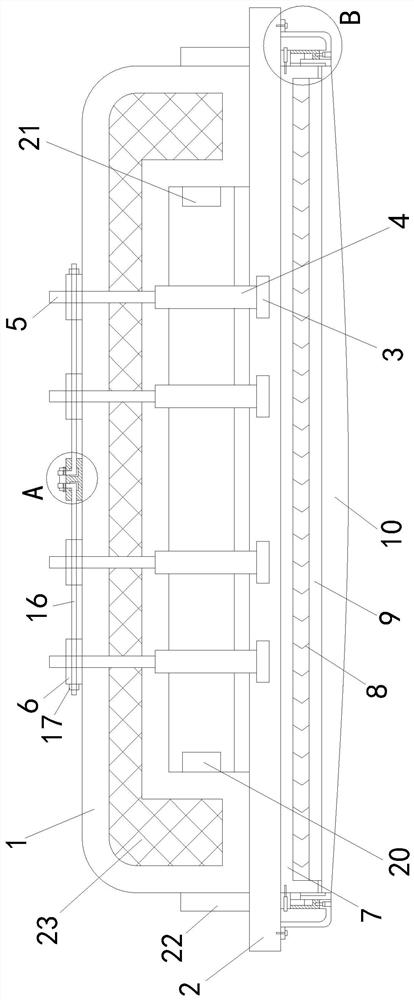

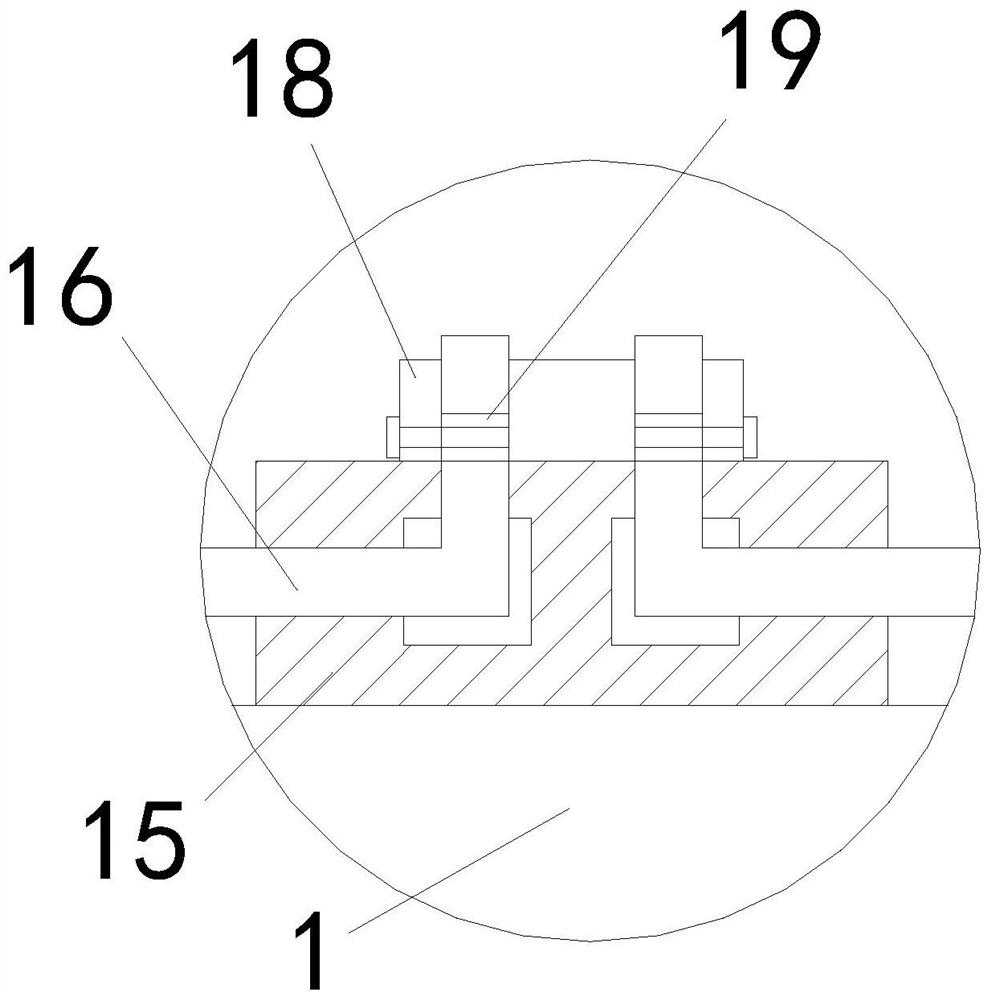

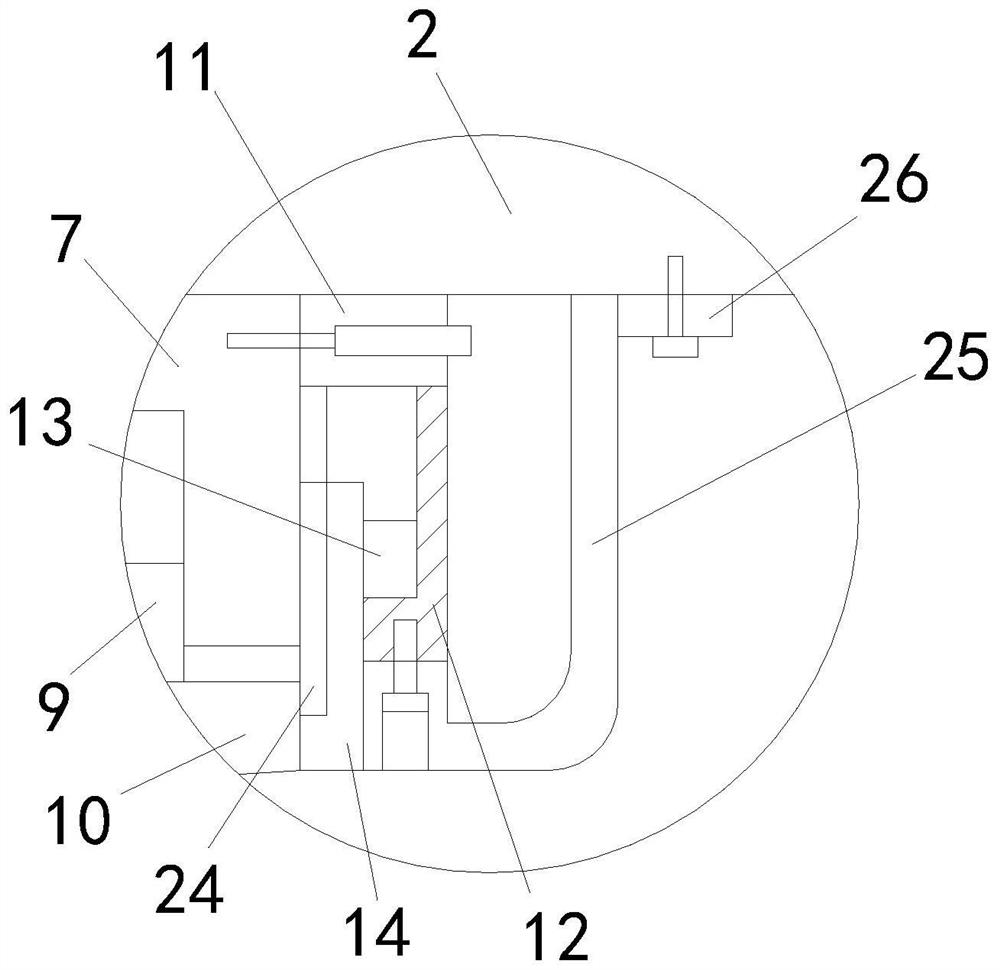

[0028] see Figure 1-6 , a vehicle floor structure, comprising a floor body 1, the interior of the floor body 1 is provided with a cavity, the interior of the floor body 1 is provided with a cushion pad 23, and the cushion pad 23 is a rubber pad; part of the impact force is buffered by the cushion pad 23, After receiving the impact force, the deformation of the base plate body 1 is reduced, and the solid base plate body 1 is replaced by the internal cavity of the base plate body 1, thereby reducing the weight of the base plate body 1. The bottom end of the base plate body 1 is provided with a transfer plate 2, the middle part of the adapter plate 2 is rotatably connected with a circular plate 3, the middle part of the adapter plate 2 is provided with round holes corresponding to each circular plate 3, and the top of each circular plate 3 is fixedly connected with a support shaft 4, each The tops of the support shafts 4 are all fixedly connected with screw rods 5, and the tops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com