Top-attached fabricated suspended ceiling system and mounting method thereof

A prefabricated, suspended ceiling technology, applied in the direction of ceilings, building components, buildings, etc., can solve the problems of high occupied floors, low floor heights, slow installation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

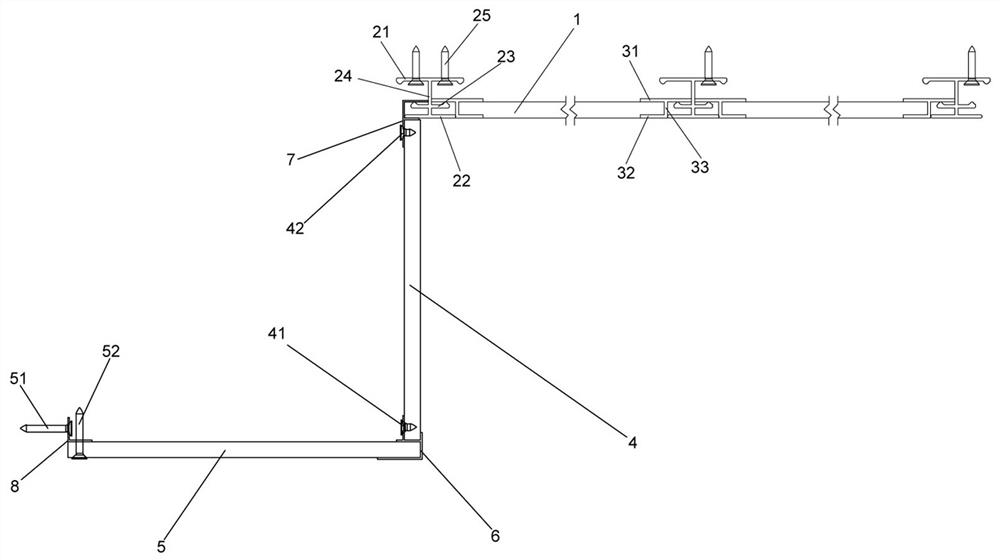

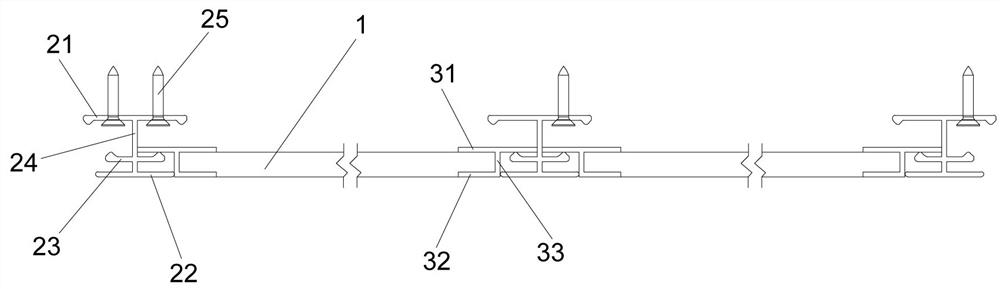

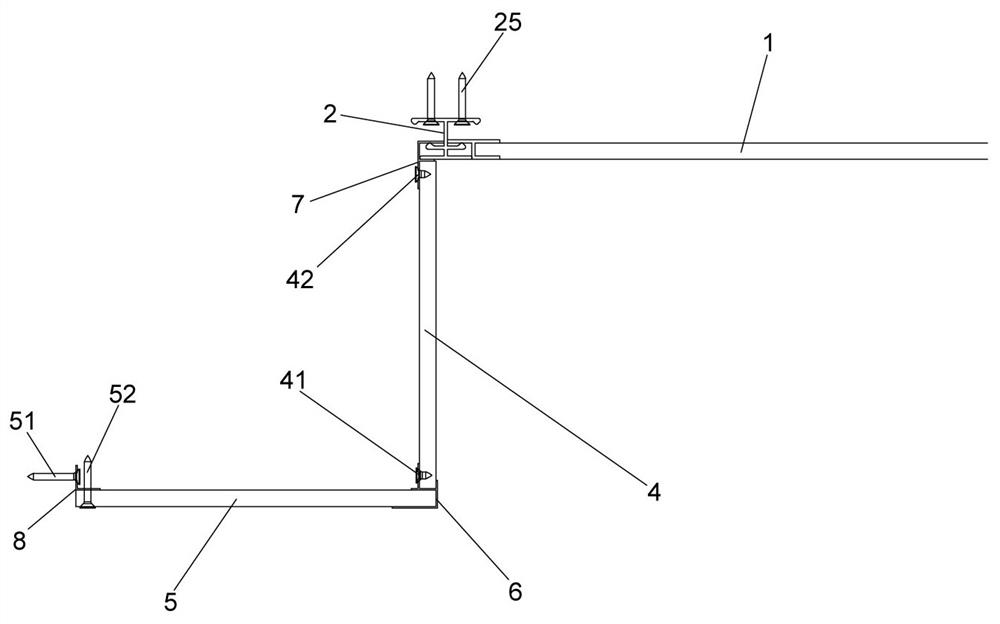

[0046] Embodiment one: if Figures 1 to 11 As shown, it is only one embodiment of the present invention, a ceiling assembly type ceiling system, including a high part and a low part, the high part includes a base plate 1 and a first mounting part for installing the base plate 1 2. The end of the base plate 1 is provided with a second mounting part 3, and the first mounting part 2 includes a vertical plate 24, a first horizontal plate 21 disposed on the end of the vertical plate 24, a first horizontal plate 21 disposed on the vertical plate 24 the second horizontal plate 22 at one end away from the first horizontal plate 21 and the third horizontal plate 23 arranged between the first horizontal plate 21 and the second horizontal plate 22, the second mounting part 3 includes An upper plate 31 connected to the upper surface of the substrate 1, a lower plate 32 connected to the lower surface of the substrate 1, and a side plate 33 for connecting the upper plate 31 and the lower pl...

Embodiment 2

[0058] Embodiment two, such as Figures 1 to 11 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in a ceiling assembly type ceiling system of the present invention, the lower surface of the end of the base plate 1 is provided with a 32 into the groove 11.

[0059] Of course, the depth of the groove 11 on the base plate 1 is equal to the thickness of the lower plate 32, and the length of the groove 11 is not less than the length of the lower plate 32. Generally speaking, the length of the groove 11 is equal to the thickness of the lower plate 32. 32, when the second mounting part 3 is installed on the base plate 1, the lower plate 32 is just inserted into the groove 11 without occupying the floor height.

[0060] In addition, the side of the second horizontal plate 22 away from the first horizontal plate 21 is flush with the side of the lower plate 32 away from the upper plate 31 , which is actually the bottom of the second ho...

Embodiment 3

[0065] Embodiment three, such as Figures 1 to 11 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in a ceiling assembly type ceiling system of the present invention, the number of the first screw 41 and the second screw 42 are at least one .

[0066] It should be noted that the lengths of the first screws 41 and the second screws 42 are not greater than the thickness of the vertical trim 4 , so as to ensure that the first screws 41 and the second screws 42 will not be separated from the vertical trim 4 . Leaking out on the other side, the aesthetics of the dropped ceiling are better.

[0067] Also, the number of the third screw 51 and the fourth screw 52 is at least one, so that the structural stability of the vertical decorative panel 4 is better.

[0068] Of course, the length of the fourth screw 52 is not less than the thickness of the horizontal trim 5 , and the fourth screw 52 needs to pass through the horizontal trim ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com