Internal combustion engine and method for determining leaks at fluid-conducting components thereof

A technology of internal combustion engine and fluid, which is applied in the leakage field of components, and can solve problems such as expensive and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

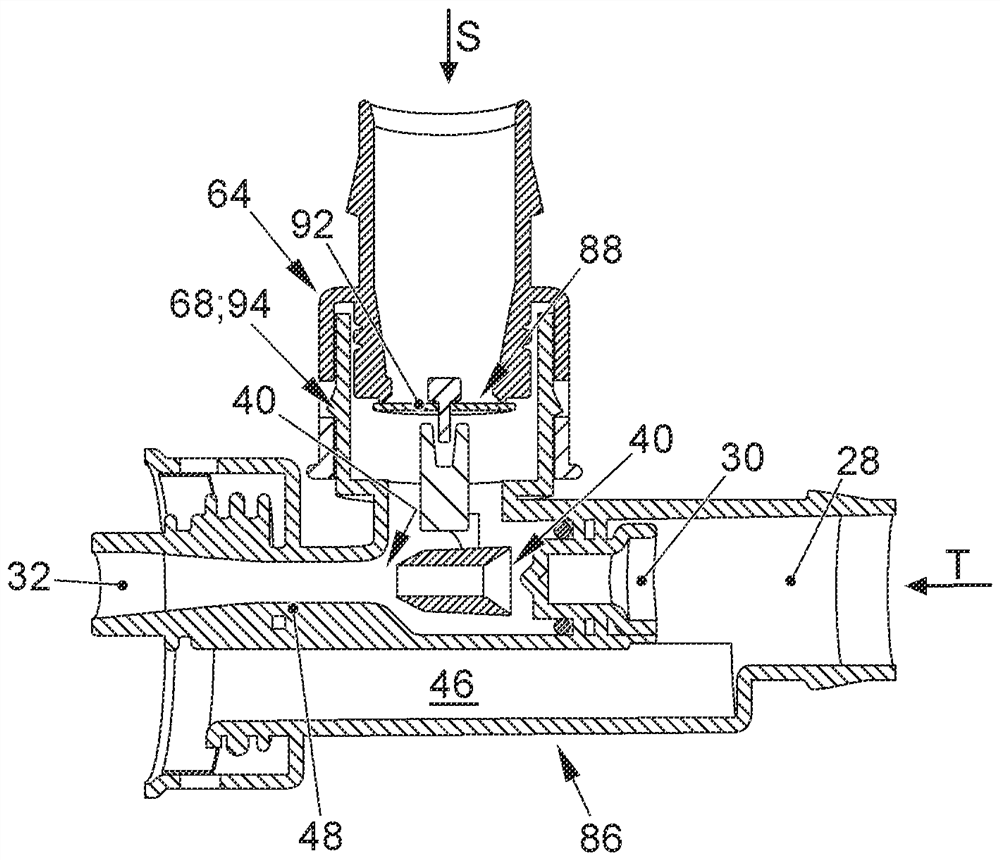

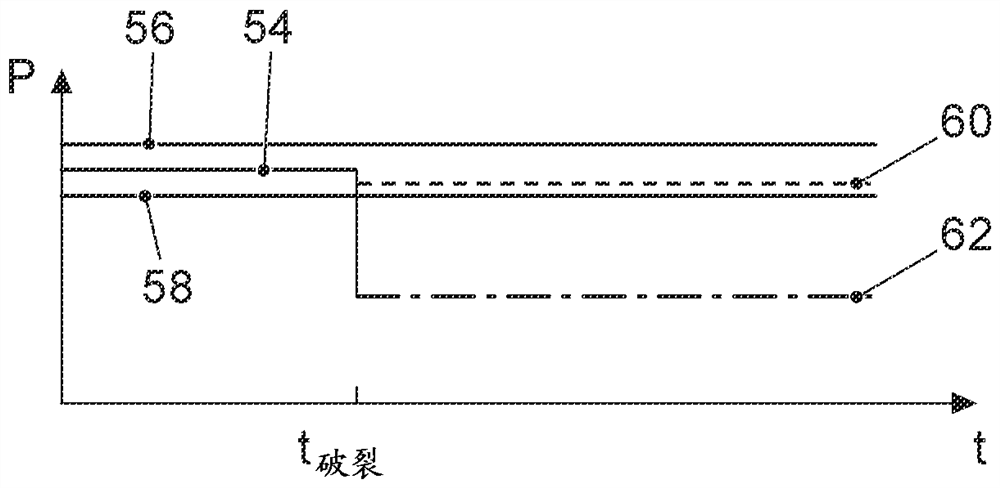

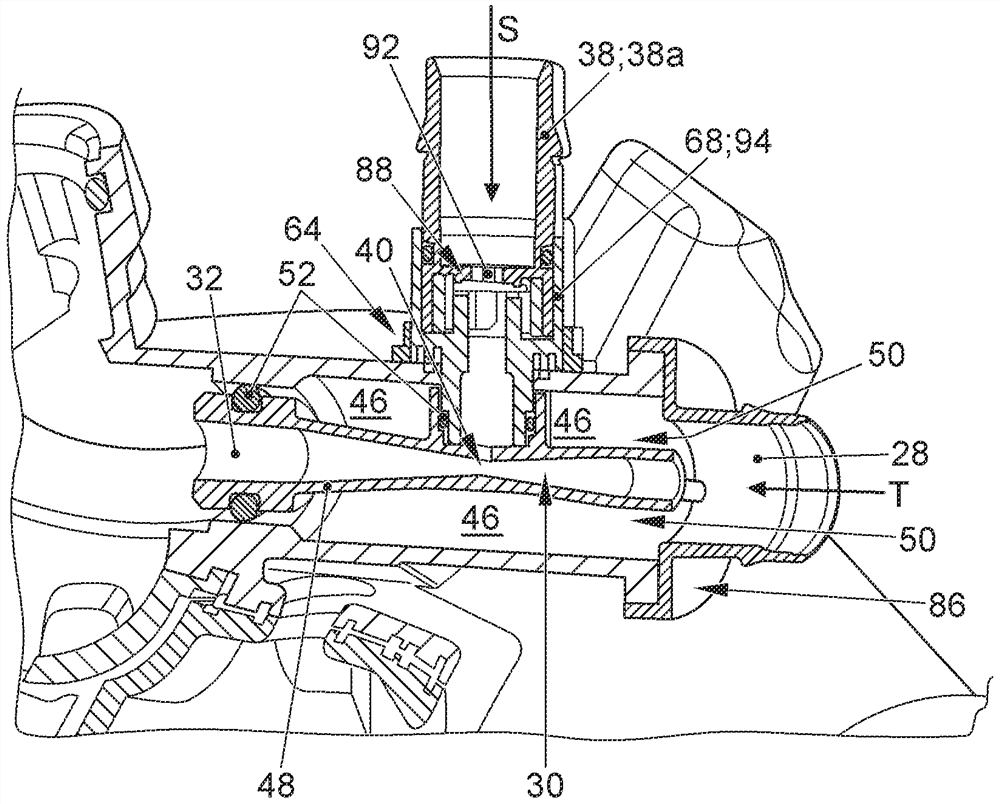

[0035] figure 1 An internal combustion engine 10 according to the invention is shown schematically, wherein only those elements which may be relevant in connection with the invention are explained in detail below.

[0036] An intake section 12 is provided in internal combustion engine 10 , via which fresh air from the atmosphere can be conveyed to combustion chambers 14 . An intake air guide hood 18 is provided as the fluid-guiding component 16 of the intake section 12 . A compressor of an exhaust gas turbocharger 20 and a throttle valve 22 follow downstream of the intake air guide bell 18 .

[0037] The area downstream of the compressor is called pressure pipe 24 . At a branch 26 downstream of the exhaust gas turbocharger 20 , a partial flow T branches off from the pressure line 24 , wherein the partial flow T is conducted as drive flow into the inflow channel 28 of the Venturi nozzle 30 . The outflow channel 32 of the Venturi nozzle 30 is led back into the intake hood 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com