Low-temperature fragrance-fixing hotpot condiment and preparation method thereof

A hot pot base material and aroma-fixing technology, which is applied in the fields of ultra-high pressure food processing, food science, application, etc., can solve the problems of poor flavor and insufficient aroma of hot pot base material, avoid the loss of fat flavor, increase product yield, The effect of reducing the frying temperature and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

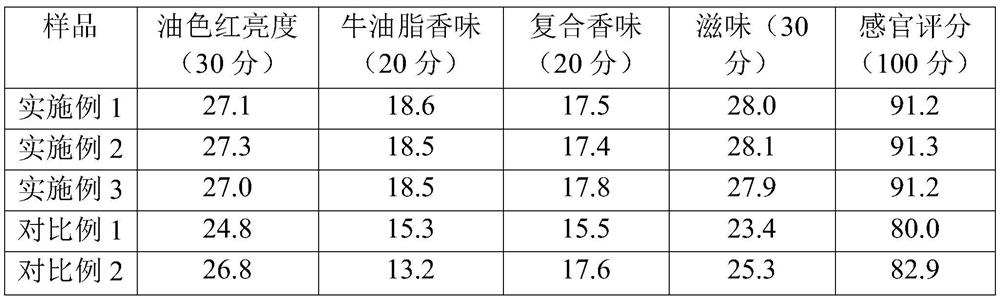

Examples

Embodiment 1

[0028] A low-temperature solid fragrance hot pot bottom material, the preparation method of which comprises the following steps:

[0029] (1) Mix glutinous rice cake chili, Chinese prickly ash powder, spice powder, minced garlic, red palm oil and 1 / 3 of butter, and process it under ultra-high pressure at 350MPa and 80°C for 18 minutes to obtain Mixture 1;

[0030] (2) Heat 1 / 3 of the butter to 138°C, add scallion and ginger paste and fry for 4 minutes to get Mixture 2;

[0031] (3) Cool down the mixture 2 obtained in step (2) to 130°C, then add bean paste, tempeh, shiitake mushrooms and rock sugar in sequence, mix and fry at 130°C for 3 minutes to obtain mixture 3;

[0032] (4) Cool the mixture 3 obtained in step (3) to 102°C, then add the mixture 1 obtained in step (1), then add the remaining butter, onion powder and pork rib powder, and fry for 20 minutes to obtain mixture 4;

[0033] (5) Cool the mixed material 4 obtained in step (4) to 85°C, then add flavoring agent, edib...

Embodiment 2

[0037] A low-temperature solid fragrance hot pot bottom material, the preparation method of which comprises the following steps:

[0038] (1) Mix glutinous rice cake chili, Chinese prickly ash powder, spice powder, minced garlic, red palm oil and 1 / 3 of butter, and process it at 380MPa and 70°C for 17 minutes under ultra-high pressure to obtain Mixture 1;

[0039] (2) Heat 1 / 3 of the butter to 140°C, add scallion and ginger paste and fry for 3 minutes to get Mixture 2;

[0040] (3) Cool down the mixture 2 obtained in step (2) to 132°C, then add bean paste, fermented soy beans, shiitake mushrooms and rock sugar in sequence, mix and fry at 132°C for 3 minutes to obtain mixture 3;

[0041] (4) Cool the mixture 3 obtained in step (3) to 104°C, then add the mixture 1 obtained in step (1), then add the remaining butter, onion powder and pork rib powder, and fry for 23 minutes to obtain mixture 4;

[0042] (5) Cool the mixed material 4 obtained in step (4) to 85°C, then add flavorin...

Embodiment 3

[0046] A low-temperature solid fragrance hot pot bottom material, the preparation method of which comprises the following steps:

[0047] (1) Mix glutinous rice cake chili, Chinese prickly ash powder, spice powder, minced garlic, red palm oil and 1 / 3 of butter, and process it under ultra-high pressure at 400MPa and 80°C for 18 minutes to obtain Mixture 1;

[0048] (2) Heat 1 / 3 of the butter to 145°C, add scallion and ginger paste and fry for 5 minutes to get Mixture 2;

[0049] (3) Cool down the mixture 2 obtained in step (2) to 135°C, then add bean paste, tempeh, shiitake mushrooms and rock sugar in sequence, mix and fry at 135°C for 5 minutes to obtain mixture 3;

[0050] (4) Cool down the mixture 3 obtained in step (3) to 106°C, then add the mixture 1 obtained in step (1), then add the remaining butter, onion powder and pork rib powder, and fry for 25 minutes to obtain mixture 4;

[0051] (5) Cool the mixed material 4 obtained in step (4) to 90°C, then add flavoring agent,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com