Cooling liquid circulating system of stainless steel pipe making machine

A circulating system and cooling liquid technology, applied in the direction of filtration and separation, separation method, mobile filter element filter, etc., can solve the problems of polluting the environment, wasting water resources, mixing, etc., to reduce pollution, reduce replacement frequency, and improve filtration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

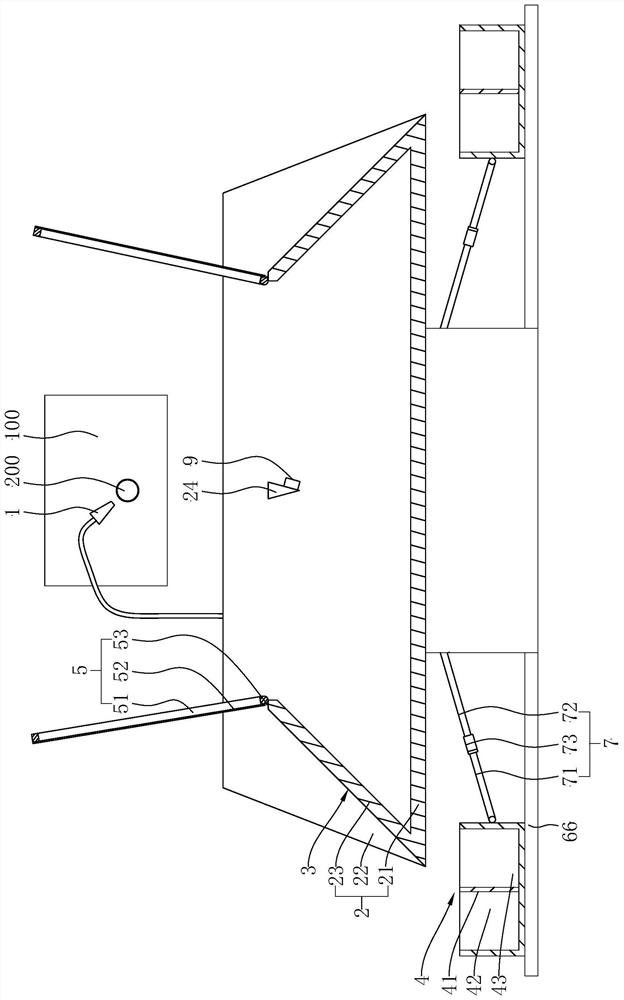

[0032] The following is attached Figure 1-5 The application is described in further detail.

[0033] The embodiment of the application discloses a cooling liquid circulation system of a stainless steel tube machine.

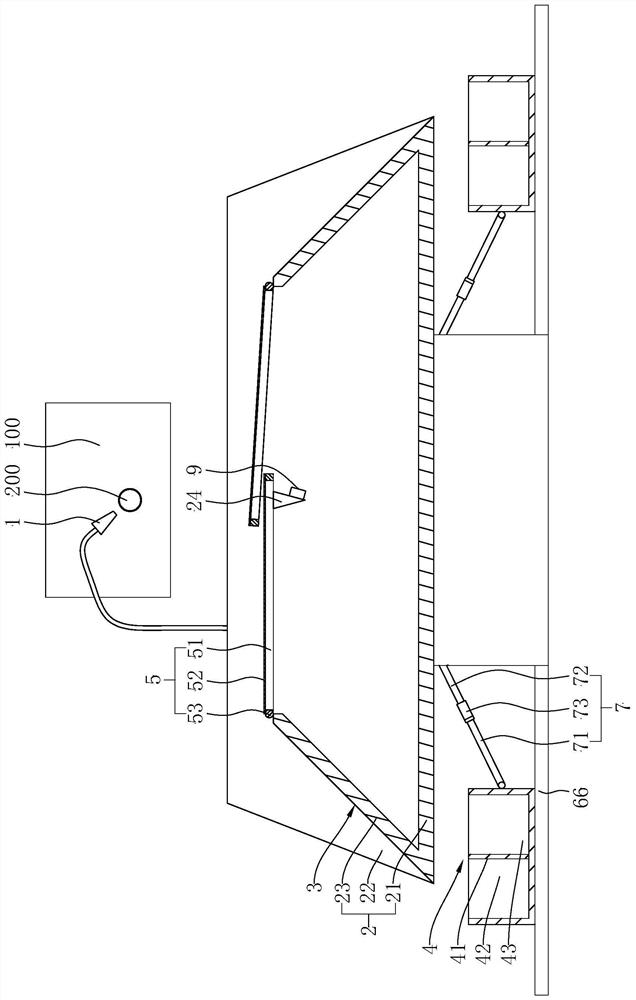

[0034] refer to figure 1 The cooling liquid circulation system of the stainless steel tube pipe machine includes a spray head 1 and a water collection tank 2, wherein the spray head 1 is installed on the pipe making machine 100 and is used to spray the coolant onto the workpiece 200, so as to realize the cooling and flushing of the workpiece 200, The water collecting tank 2 is arranged under the pipe making machine 100 and is used to receive the cooling liquid sprayed on the workpiece 200, so as to collect the cooling liquid and supply the cooling liquid to the spray head 1 through a preset water pump, so as to circulate.

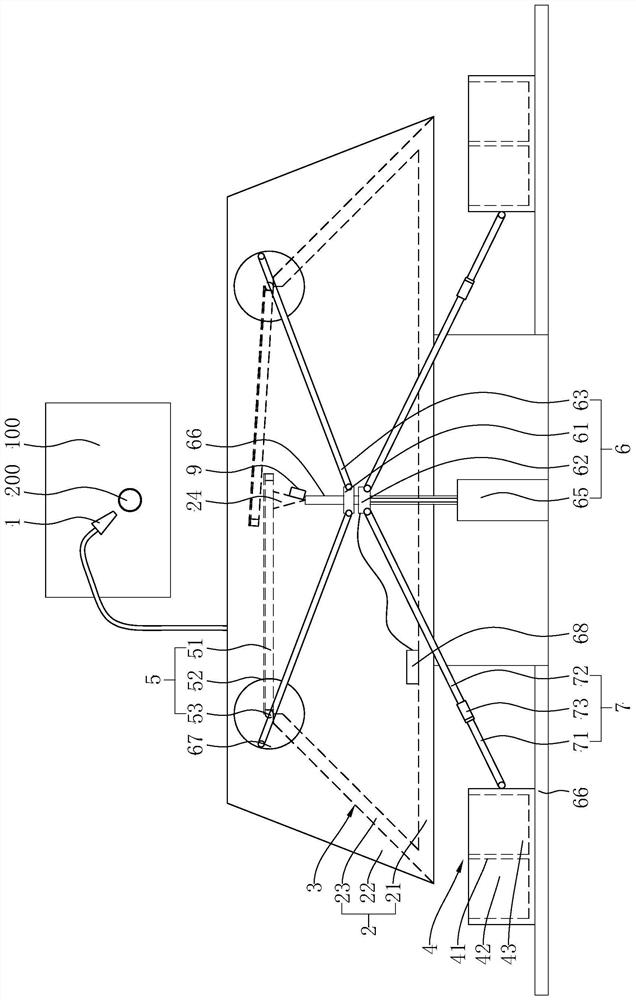

[0035] refer to figure 2 , in this embodiment, the sump 2 is provided with a filter structure 5 for intercepting debris mixed in the coo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap