Insulator cleaning device and cleaning method

A cleaning device and technology for insulators, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of cleaning insulators and other problems, and achieve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

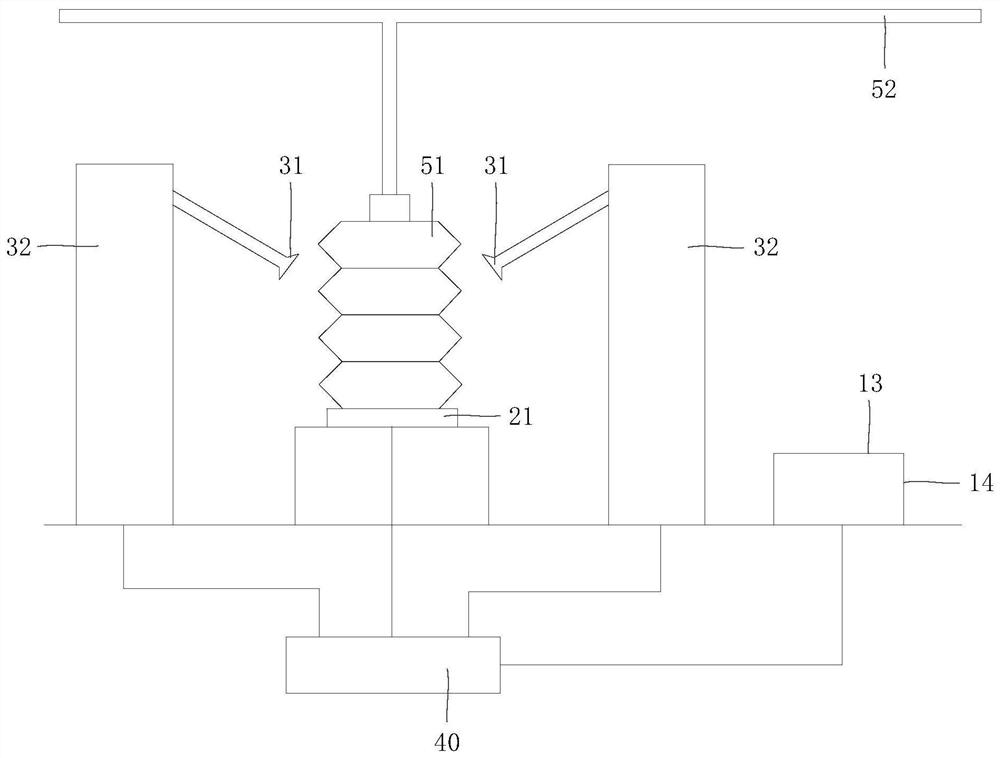

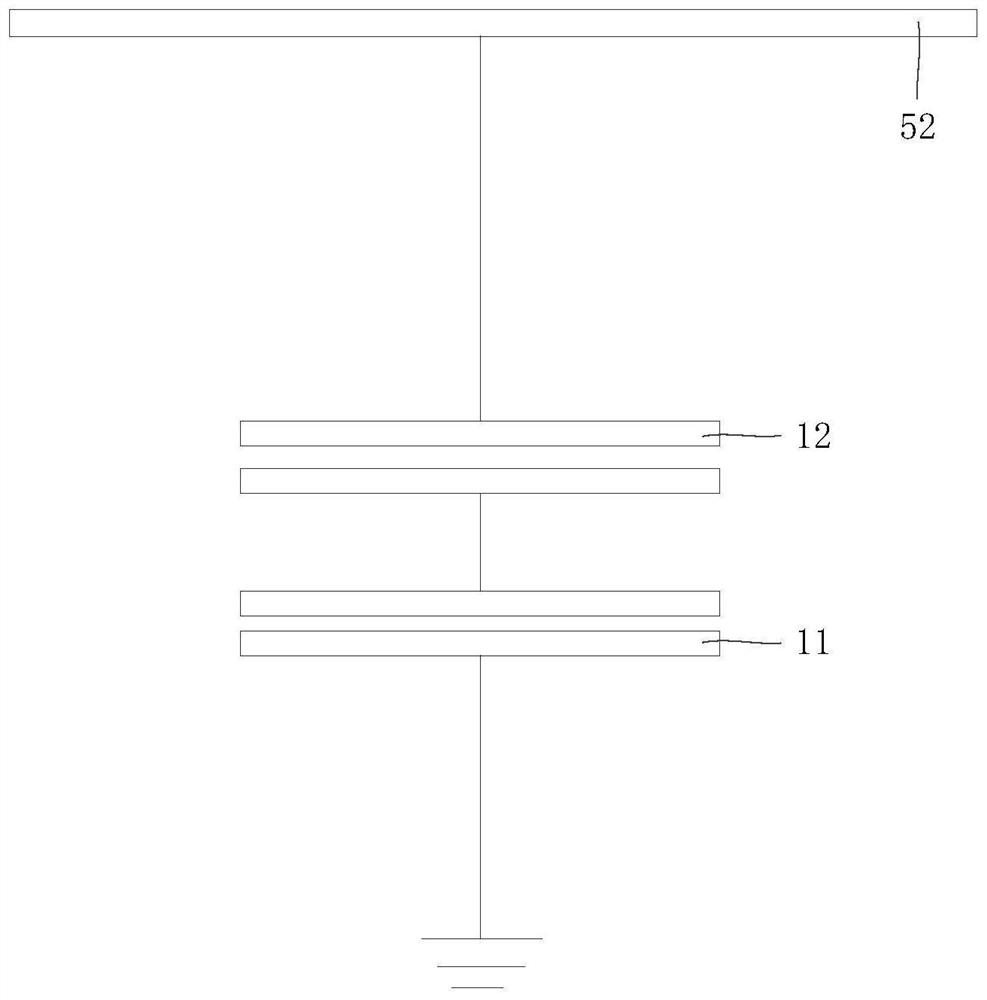

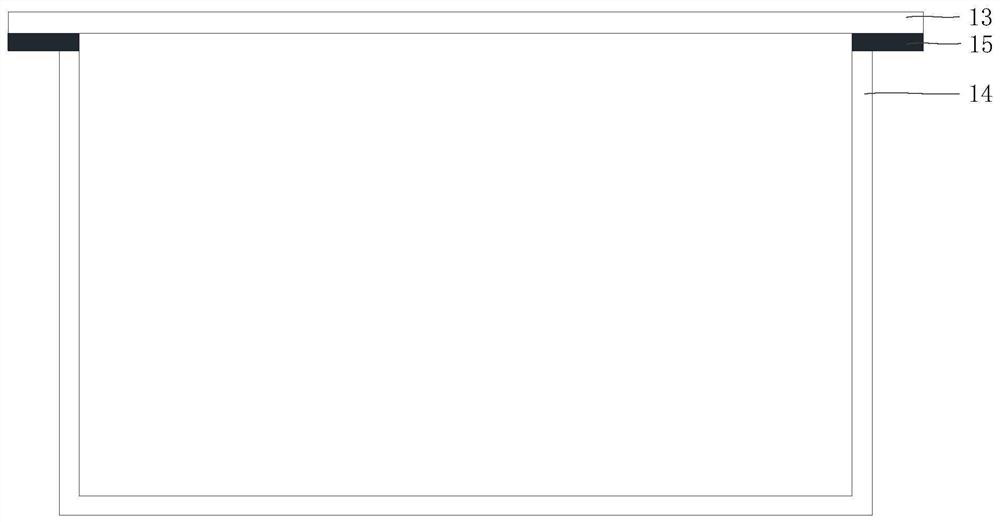

[0039] In order to solve the above problems, figure 1 It is a schematic structural diagram of an insulator cleaning device provided in Embodiment 1 of the present invention, figure 2 for figure 1 Schematic diagram of the structure of the induction plate and the shielding shell, image 3 For the schematic diagram of the voltage divider circuit, please refer to Figure 1 to Figure 3 , the present embodiment provides an insulator cleaning device, which includes a sampling assembly, a cleaning assembly and a controller 40; the sampling assembly includes a voltage sampling part and a current sampling part, the voltage sampling part is used to monitor the voltage of the catenary 52, and the current sampling part is used for To monitor the current passing through the insulator 51; the controller 40 is connected to the voltage sampling part and the current sampling part respectively, and the controller 40 obtains the voltage value measured by the voltage sampling part and the curre...

Embodiment 2

[0077] Figure 4For the schematic flow chart of the cleaning method provided by Embodiment 2 of the present invention, please refer to Figure 4 , this embodiment provides a cleaning method, which is applied to the insulator cleaning device of the first embodiment, including: the voltage sampling part measures the voltage value of the catenary 52, and the current sampling part measures the current value passing through the insulator 51; the controller 40 Obtain the current value and the voltage value; when the controller 40 determines that the voltage value is within the preset voltage range and the current value is greater than the preset current value, the controller 40 controls the cleaning component to clean the insulator.

[0078] It can be understood that the controller may include an analog input module, a processor module, an output module and a man-machine interface. The analog input module collects the voltage across the first capacitor 11 and the voltage across the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com