Manufacturing and machining method for communication iron tower building assembly type steel structure

A processing method and steel structure technology, which is applied in the field of communication equipment, can solve the problems of irregular shape of single-layer steel structure, difficulty in ensuring the inclination angle and inclination direction of the main pole, and difficulty in ensuring the docking of the ends of the main pole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

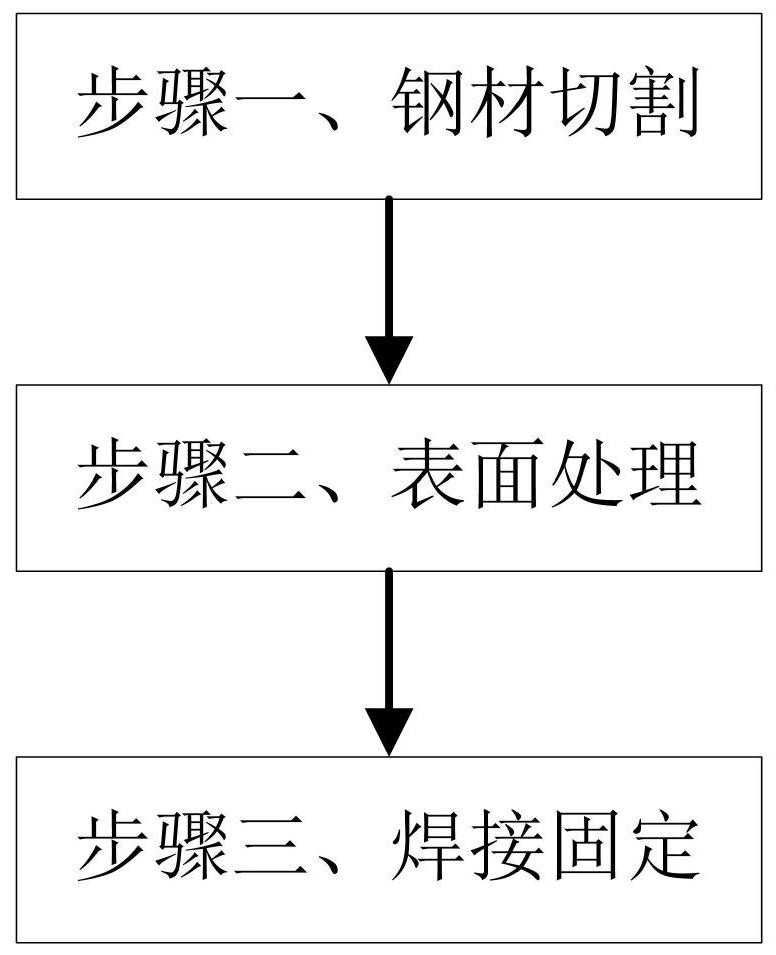

[0033] Such as figure 1 , the present embodiment provides a method for manufacturing and processing a communication tower to construct an assembled steel structure, comprising the following steps:

[0034] Step 1. Steel cutting: Cut the angle steel into four main rods of equal length, and cut the round pipe into four auxiliary rods of equal length.

[0035] Step 2, surface treatment: hot-dip galvanized anti-corrosion treatment is performed on the surface of the main rod and the auxiliary rod.

[0036] Step 3. Welding and fixing: Weld the surface-treated main rod and auxiliary rod together to obtain a single-layer steel structure.

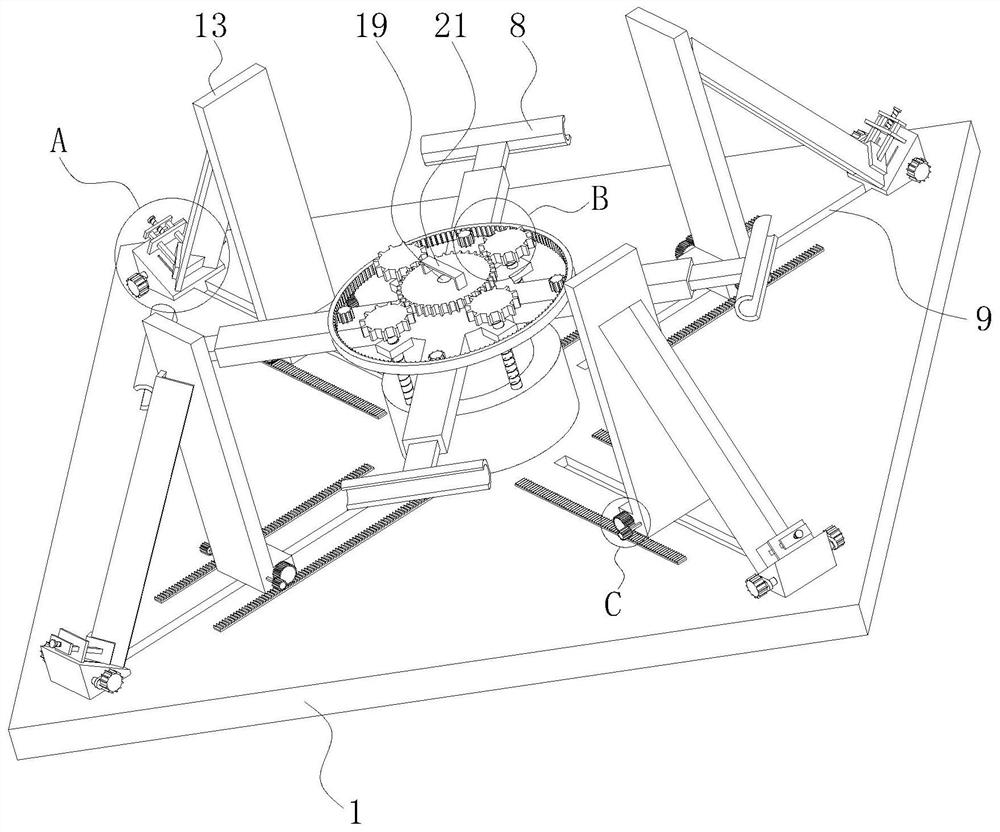

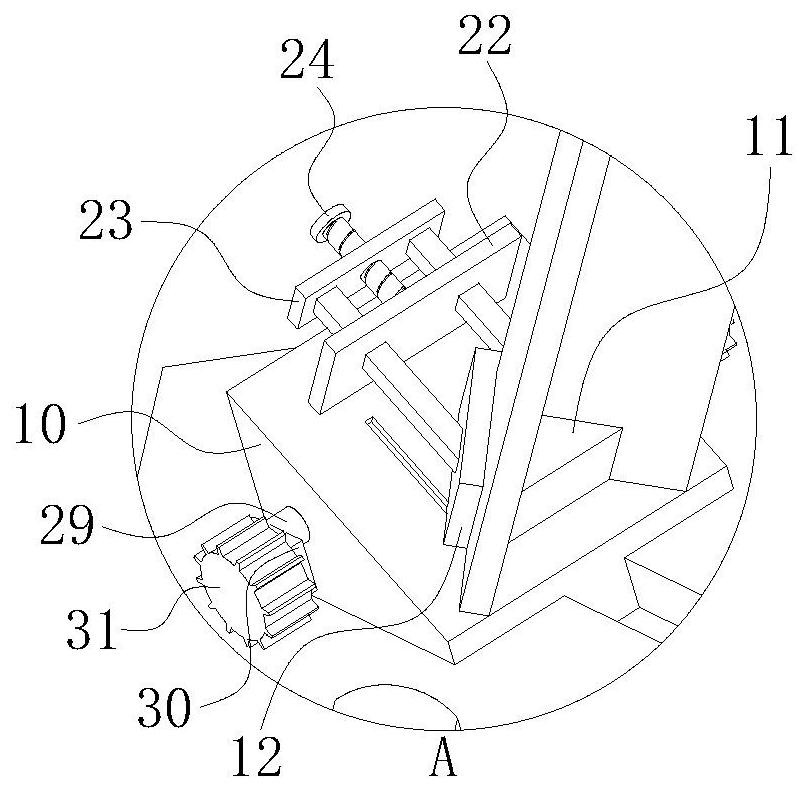

[0037] Among them, step three uses such as Figure 2 to Figure 7 The assembly-type steel structure manufacturing and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com