Multi-shaft adjustable support assembling device and assembling process

An assembly device and shaft technology, which is applied in assembly machines, metal processing, manufacturing tools, etc., can solve problems such as troublesome assembly process, and achieve the effect of efficient assembly, simple and easy-to-understand assembly process, and simple and fast action process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following is attached Figure 1-17 The application is described in further detail.

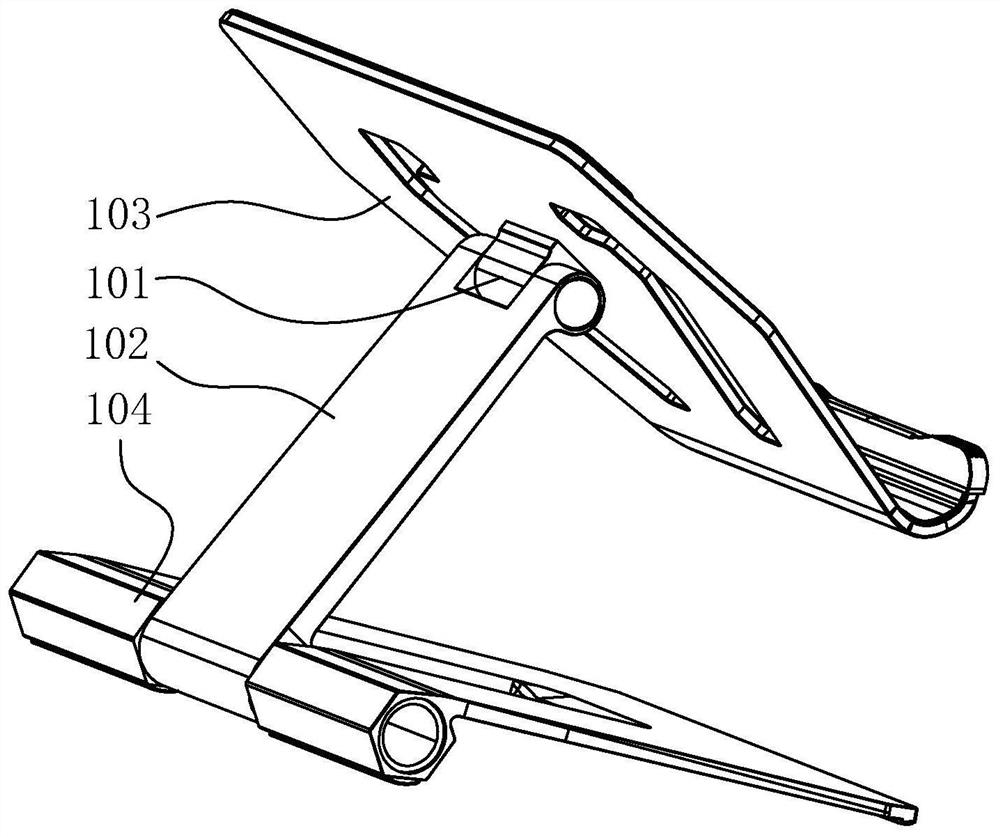

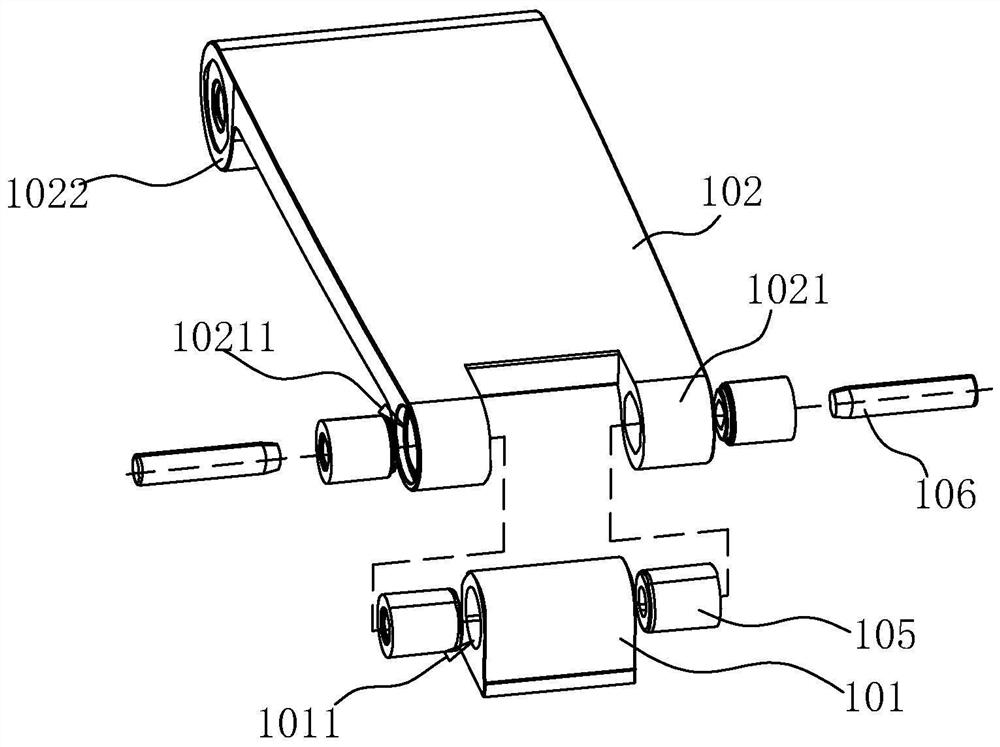

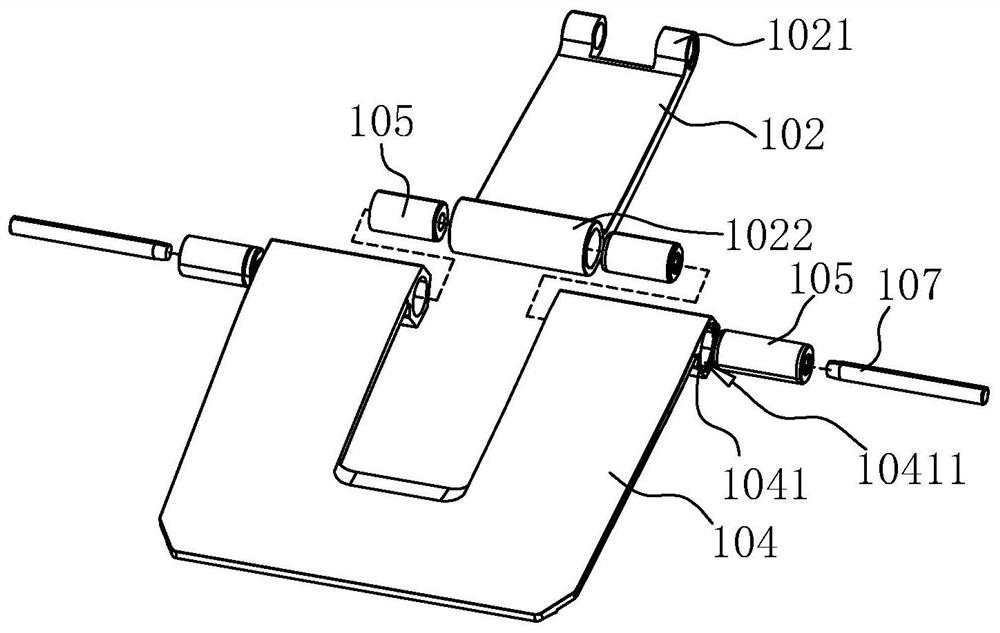

[0060] The embodiment of the present application discloses a multi-axis adjustable bracket, refer to figure 1 and figure 2 , the bracket includes a connecting block 101, a support arm 102, a supporting plate 103, a base 104, a bushing 105, a first shaft 106 and a second shaft 107, the supporting plate 103 is fixedly mounted on the connecting block 101, and the supporting plate 103 can be The electronic equipment is supported and placed; among them, in order to realize the assembly of various components, a first installation hole 1011 is provided through the connection block 101, and two shaft sleeves 105 can be filled in the first installation hole 1011; in addition, the support arm 102 is arranged in the shape of a long strip. One end of the support arm 102 is integrally connected with two first installation parts 1021. The first installation part 1021 is provided with a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com