Dustproof type hot runner temperature control box for injection mold

An injection mold and dust-proof technology, which is applied in the field of dust-proof hot runner temperature control box, can solve the problems of blocking the external heat dissipation of electrical components, achieve the effect of improving the cooling effect and accelerating the heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

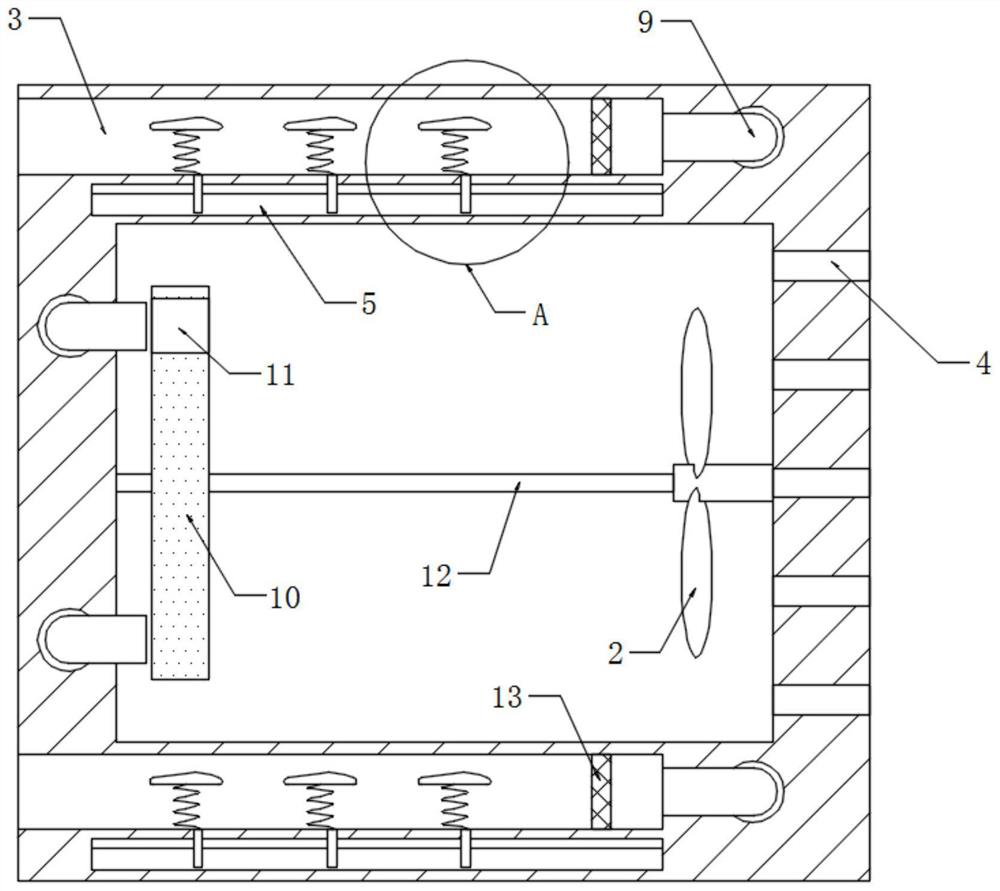

[0023] refer to Figure 1-2 , a dust-proof hot runner temperature control box for injection molds, including a box body 1, a cooling fan 2 is installed in the box body 1, it should be noted that the cooling fan 2 adopts an axial flow fan, so that the box body 1 The air flow inside is horizontal.

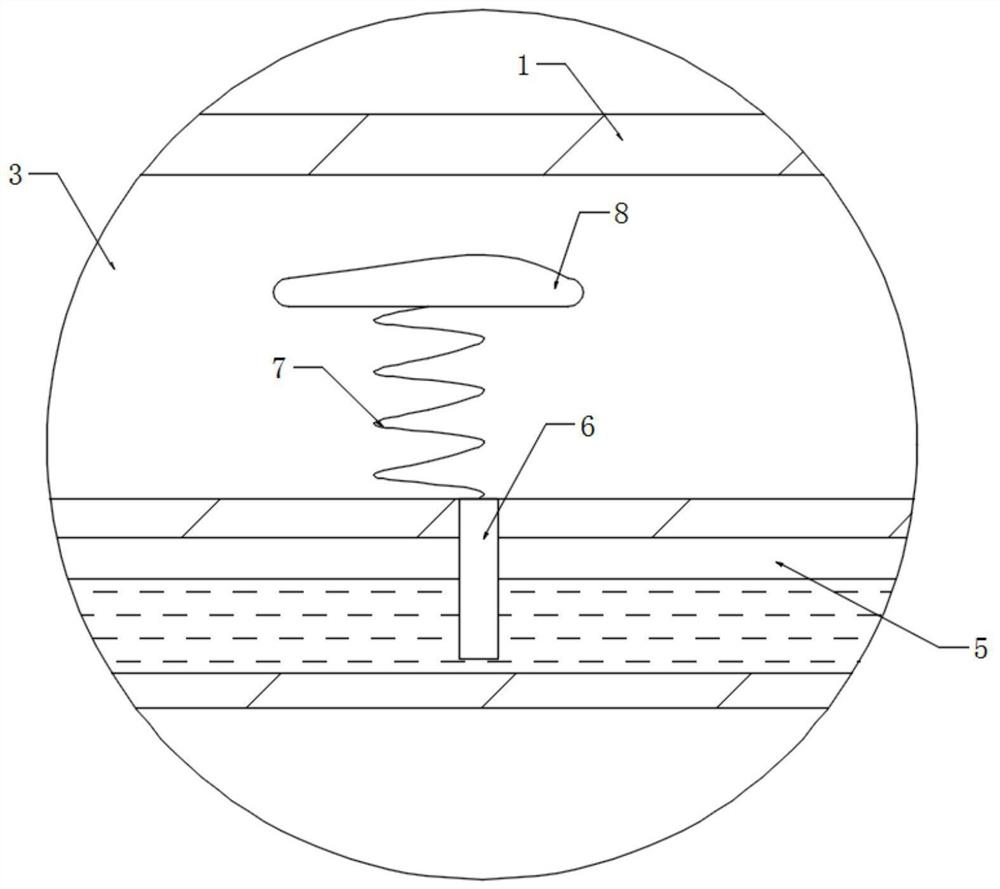

[0024] The upper and lower ends of the box body 1 are provided with air-introduction grooves 3, and the side walls of the box body 1 are provided with air outlets 4. The air-induction grooves 3 communicate with the inside of the box body 1 through copper pipes 9, and the air-induction grooves 3 are embedded with The filter screen 13, the filter screen 13 can block part of the volume of impurities and dirt, and prevent it from entering the inside of the box body 1 to form pollution. And the filter screen 13 is arranged on one side close to the air inlet end of the copper pipe 9 . A plurality of vibrating springs 7 are fixedly connected to the inner bottom of the air induction groove...

Embodiment 2

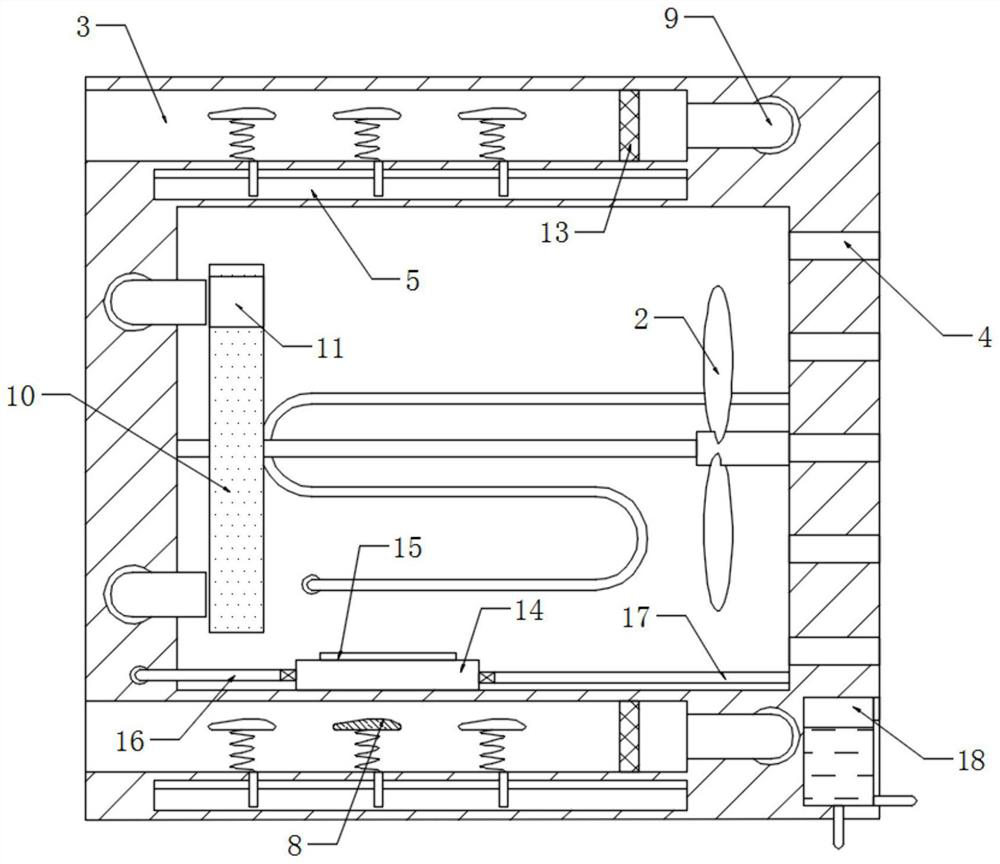

[0032] refer to image 3 , different from Embodiment 1, the bottom of the box body 1 is fixedly connected with an elastic cylinder 14, the side wall of the box body 1 is provided with a second liquid storage tank 18, and the elastic cylinder 14 communicates with the second liquid storage tank 18. The one-way liquid inlet pipe 16 and the one-way liquid outlet pipe 17, the one-way liquid inlet pipe 16 only allows the cooling liquid to flow from the second liquid storage tank 18 to the elastic cylinder 14, and the one-way liquid outlet pipe 17 only allows the cooling liquid to flow from the elastic cylinder 14 To flow to the second liquid storage tank 18, specifically, a check valve can be installed in the pipeline.

[0033] It should be noted that, if figure 2 As shown, the one-way liquid inlet pipe 16 is arranged in the box body 1 in a serpentine shape, which can increase the contact area with the electrical equipment in the box body 1, thereby increasing the heat dissipation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com