Comprehensive utilization device for waste heat of oil extraction sewage in oil field

A technology for oil extraction sewage and waste heat, which is applied in water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc. Thoroughly, improve the utilization rate, and increase the effect of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

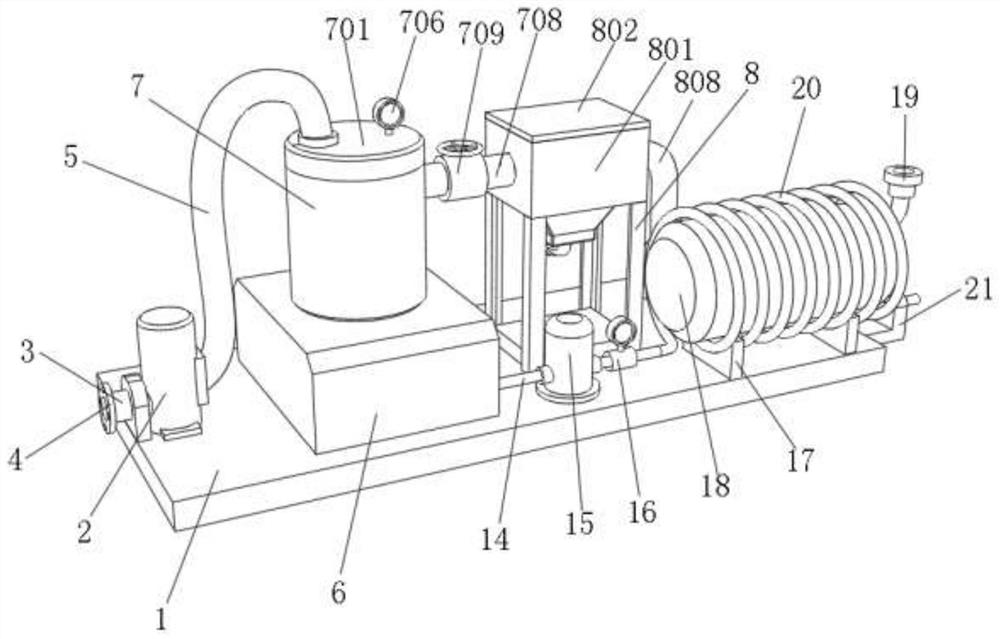

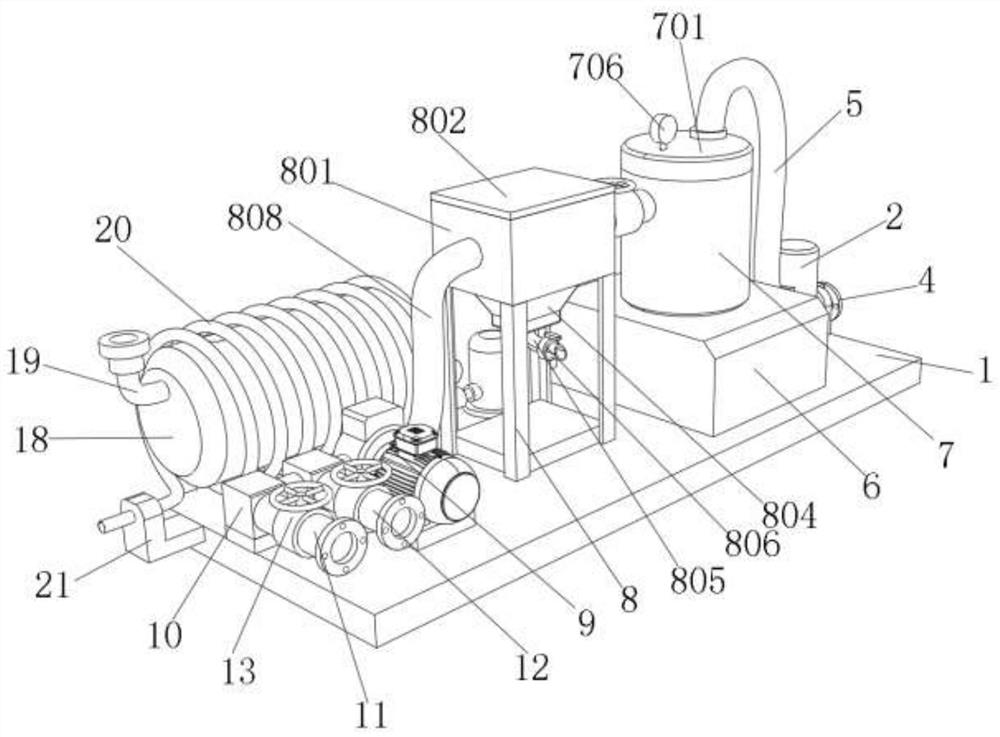

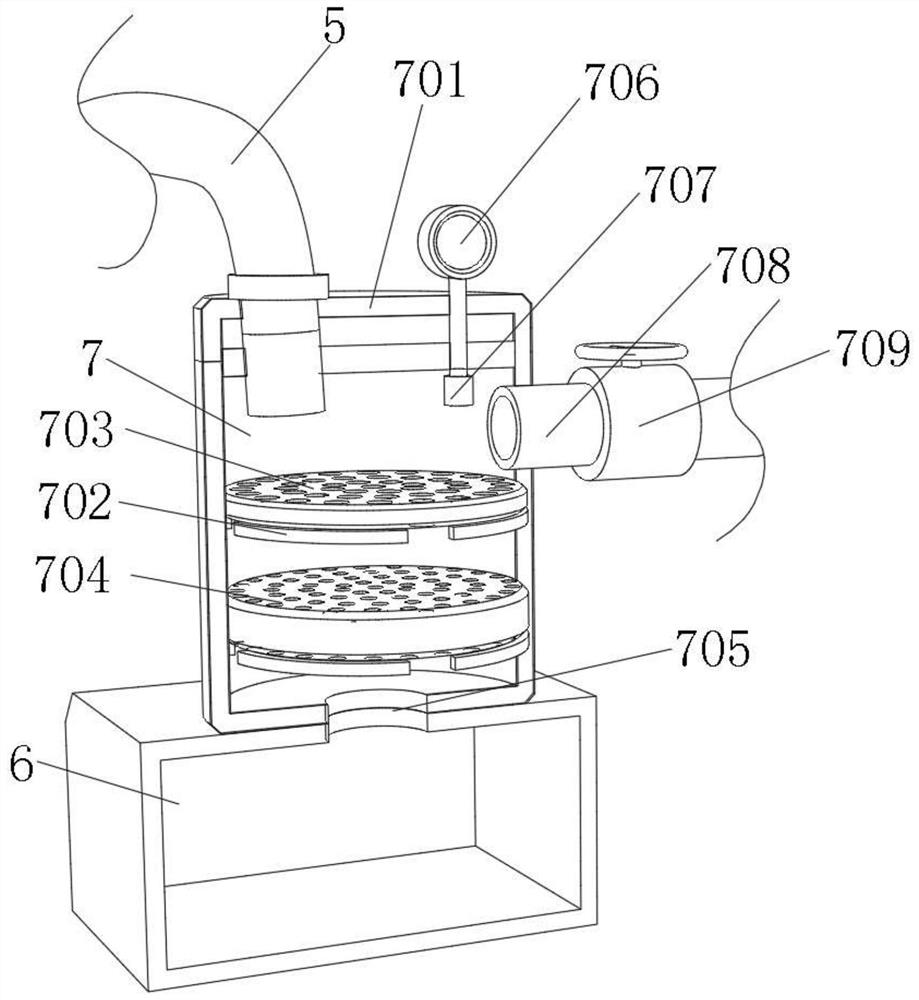

[0032] refer to Figure 1-Figure 4, a device for comprehensive utilization of waste heat from oilfield sewage, comprising a bottom plate 1, a sewage pump 2 is fixed on the upper surface of the bottom plate 1 by bolts, and a water inlet pipe 5 is plugged into the outlet end of the sewage pump 2, and a water inlet pipe 5 is inserted on the upper surface of the bottom plate 1 by bolts. The water collecting tank 6, and the upper surface of the water collecting tank 6 is provided with a filter mechanism, the upper surface of the bottom plate 1 is fixed with a support leg 8 by bolts, and the top of the support leg 8 is fixed with a condensate tank 801 by bolts, and the setting of the condensate tank 801 can prevent steam Further utilization of waste heat can solve the problem of domestic water in the mining area to a large extent while utilizing waste heat. The top of the condensate tank 801 is clamped with a cover plate 802, and the bottom of the cover plate 802 is fixed with a cond...

Embodiment 2

[0036] refer to Figure 5-Figure 6 , a device for comprehensive utilization of waste heat from oilfield oil extraction sewage, comprising a connection hose 22 plugged into one end of an outlet pipe 805, a second support seat 2201 fixed on the upper surface of the bottom plate 1 by bolts, and a second support seat 2201 fixed on the top of the second support seat 2201 by bolts The second filter barrel 2202, the setting of the second filter barrel 2202, can further filter and sterilize the condensed water, to ensure that the condensed water has a certain safety, and can solve the water problem in the mining area while also improving Utilization of waste heat from oil production sewage, the other end of the second filter barrel 2202 is plugged with a second connecting pipe 2206, and the inner wall of the second filter barrel 2202 is clamped with an activated carbon layer 2205, and the activated carbon layer 2205 will filter the water. One side of the inner wall of the filter barre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap