Non-turning making method of medium-high temperature Daqu

A medium-high temperature Daqu and medium-high temperature technology is applied in the field of Daqu production, which can solve the problems of easy breeding of Penicillium, poor stability of koji medicine, and high labor intensity for turning koji, so as to prevent Penicillium infection, improve the quality of Daqu, and stabilize koji medicine quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

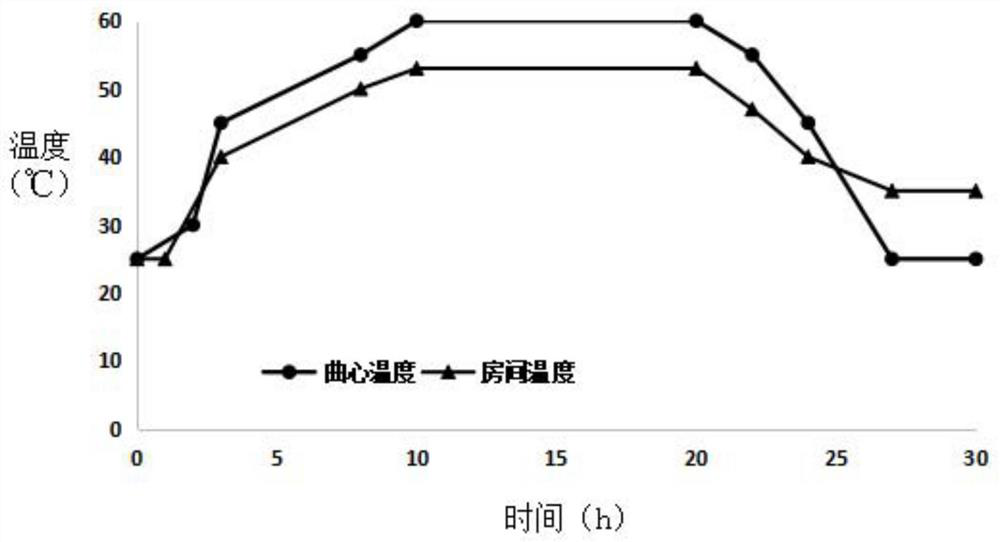

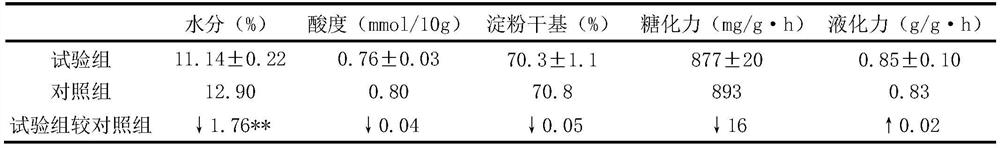

[0025] The pilot koji room of the koji-making workshop was selected as the test room to carry out the experiment of the method of making koji with medium and high temperature Daqu without overturning. The koji room entered at the same time was selected as the control room, and the fermentation process of the control room was carried out according to the traditional Daqu fermentation method. After the fermentation starts, the fan is turned on to ensure that the whole fermentation process of the test room is in a state of air circulation.

[0026] According to the room temperature and humidity, carbon dioxide and Daqu temperature changes in the test room, the researchers adjusted the fan frequency and valve opening from time to time to ensure the normal fermentation of Daqu.

[0027] The first is the constant room entry stage. When Daqu enters the room, adjust the fresh air valve to 25%, adjust the fan frequency to 20Hz, and turn on the external heating source to keep the tempera...

Embodiment 2

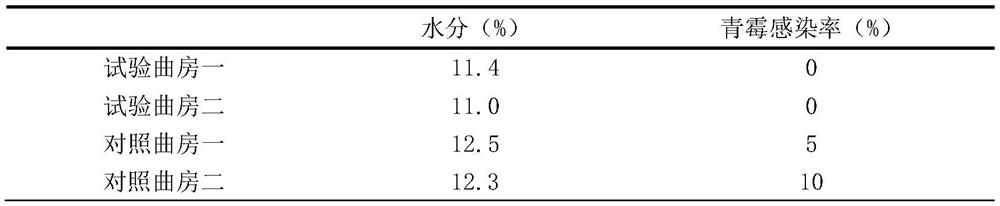

[0041] The 2 pilot-scale koji rooms in the koji making workshop of Yibin Liuchixiang Liquor Industry were selected as the test koji room to carry out the test of the method of making koji with medium and high temperature Daqu without turning over the koji. Two traditional koji rooms that entered the room at the same time were selected as the control room. trials. When the fermentation is over, the results are as follows:

[0042] Table 2: Comparison table of Penicillium infection rate in the first experiment

[0043]

[0044] Table 3: Comparison table of Penicillium infection rate in the second experiment

[0045]

[0046] From the above two tests, it can be seen that the moisture in the traditional koji room is higher than that of the test group, and Penicillium infection is prone to occur. The method of making koji with medium and high temperature Daqu without turning over the koji of the present invention has better water control, and there is basically no Penicilliu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com