Safe vehicle locking method

A safety lock and card lock technology, applied in the field of locks, can solve problems such as safety hazards, throwing out, damage, etc., and achieve the effect of reducing safety hazards and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

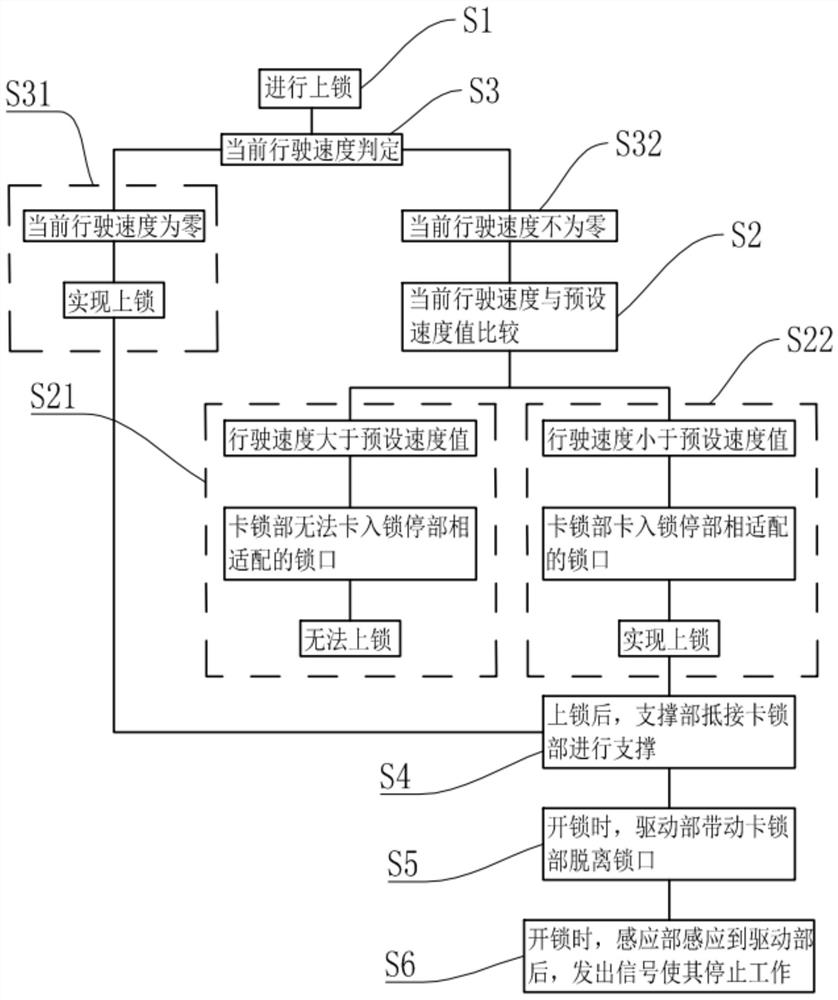

[0042] like figure 1 as shown, figure 1 It is a flow chart of the method for safely locking the car in Embodiment 1. A method for safely locking a car in this embodiment includes

[0043] S1: Perform a locking operation; the locking operation may be performed after receiving a locking instruction, or may be performed manually.

[0044] S2: compare the current driving speed with the preset speed value;

[0045] S21: If the current driving speed is greater than the preset speed value, the locking part 2 will not be able to snap into the locking opening 111 provided on the locking part 1 and matched with the locking part 2, so locking cannot be realized;

[0046] S22: If the current driving speed is lower than the preset speed value, the locking part 2 will be locked into the locking opening 111 provided on the locking part 1 and matched with the locking part 2 to realize locking.

[0047] It should be noted that the preset speed value in this embodiment is not a fixed value,...

Embodiment 2

[0067] This embodiment is a specific structure for implementing the method mentioned in Embodiment 1. Of course, this is only one embodiment, and it is not limited to this one, and it can also be realized by other structures.

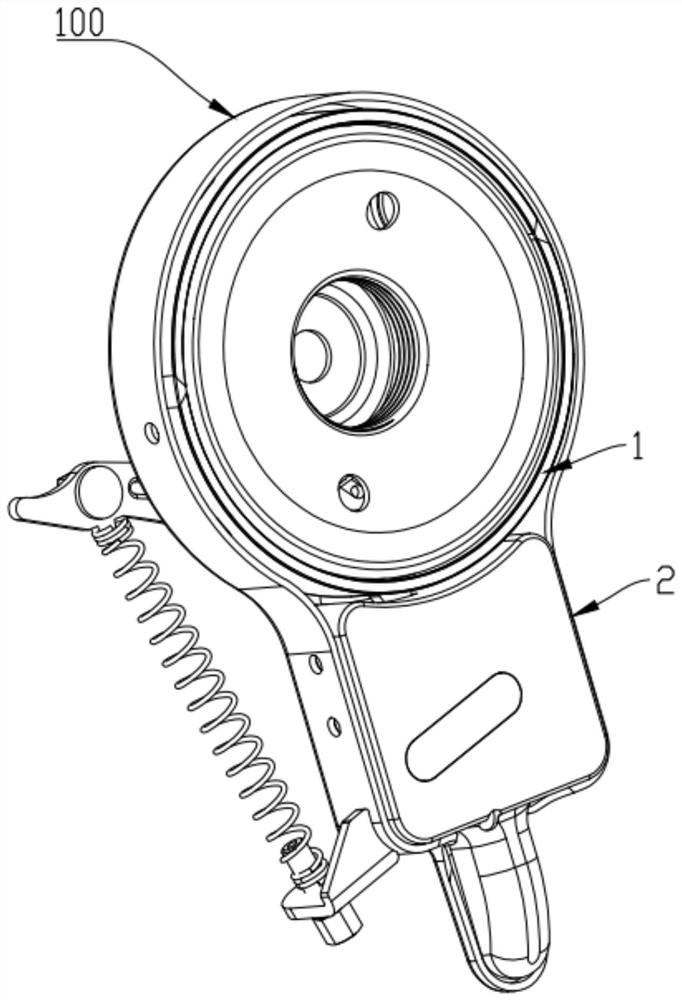

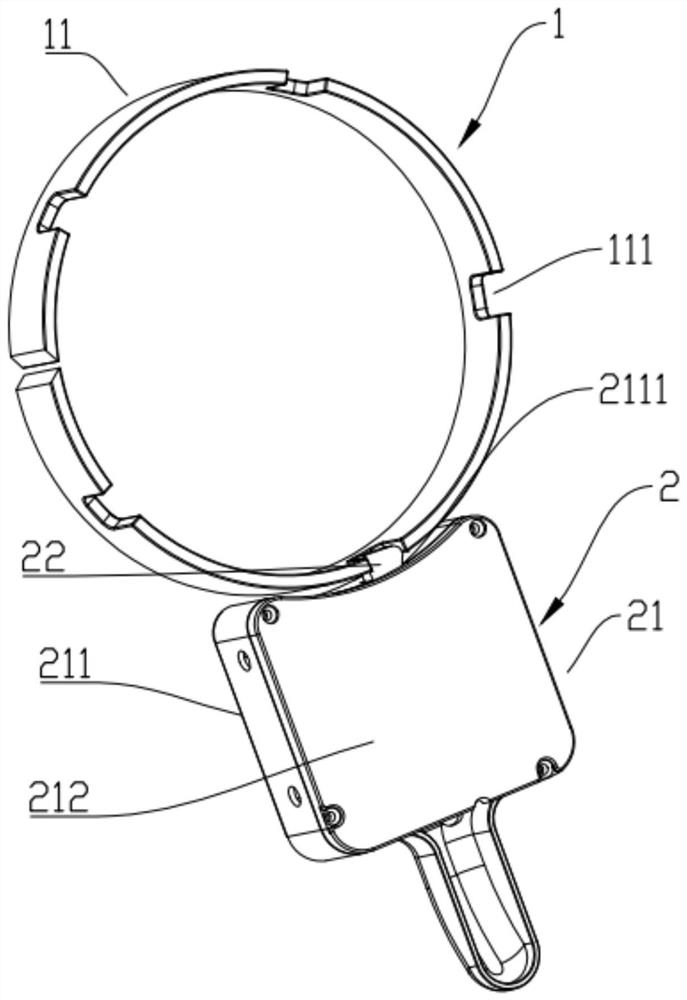

[0068] like Figure 2-Figure 4 as shown, figure 2 It is a schematic diagram of the use of the lock in Embodiment 2; image 3 It is a three-dimensional structure diagram of the lock in embodiment two; Figure 4 It is another three-dimensional structure diagram of the lock in the second embodiment. The locking part 1 includes a lock body 11 . The lock body 11 is inserted into the hub 100 and rotates together with the hub 100 . The lock opening 111 is opened on the lock body 11 . The locking part 2 includes a first carrier 21, a locking member 22 and a first elastic member 23, the first carrier 21 is arranged adjacent to the lock body 11, the locking member 22 is arranged on the first carrier 21, and the locking member 22 rotates Set on the first carr...

Embodiment 3

[0084] like Figure 10-Figure 12 as shown, Figure 10 It is the three-dimensional structure diagram of the third gear set 31223 in the third embodiment; Figure 11 It is the explosion schematic diagram of the third gear set 31223 in the third embodiment; Figure 12 It is another explosion schematic diagram of the third gear set 31223 in the third embodiment. The structure of this embodiment is similar to that of Embodiment 1, the difference is that the third gear set 31223 of this embodiment has a clutch function, and its specific structure is as follows:

[0085] Please also refer to Figure 4 and Figure 5 , the third gear set 31223 includes a wheel shaft 312231, a first sub-teeth 312232, a second sub-teeth 312233 and a third elastic member (not marked in the figure), the wheel shaft 312231 is rotatably set on the second carrier 311, and the first sub-teeth 312232 sets Set on the wheel shaft 312231, and the first sub-teeth 312232 mesh with the second gear set 31222; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com